Dismantling robot for residual refractory brick in rotary kiln and dismantling method

A technology of robots and refractory bricks, applied in manipulators, lining repair, manufacturing tools, etc., can solve the problems of heavy dust, workers' personal safety cannot be guaranteed, and affecting the rotary motion of the kiln body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

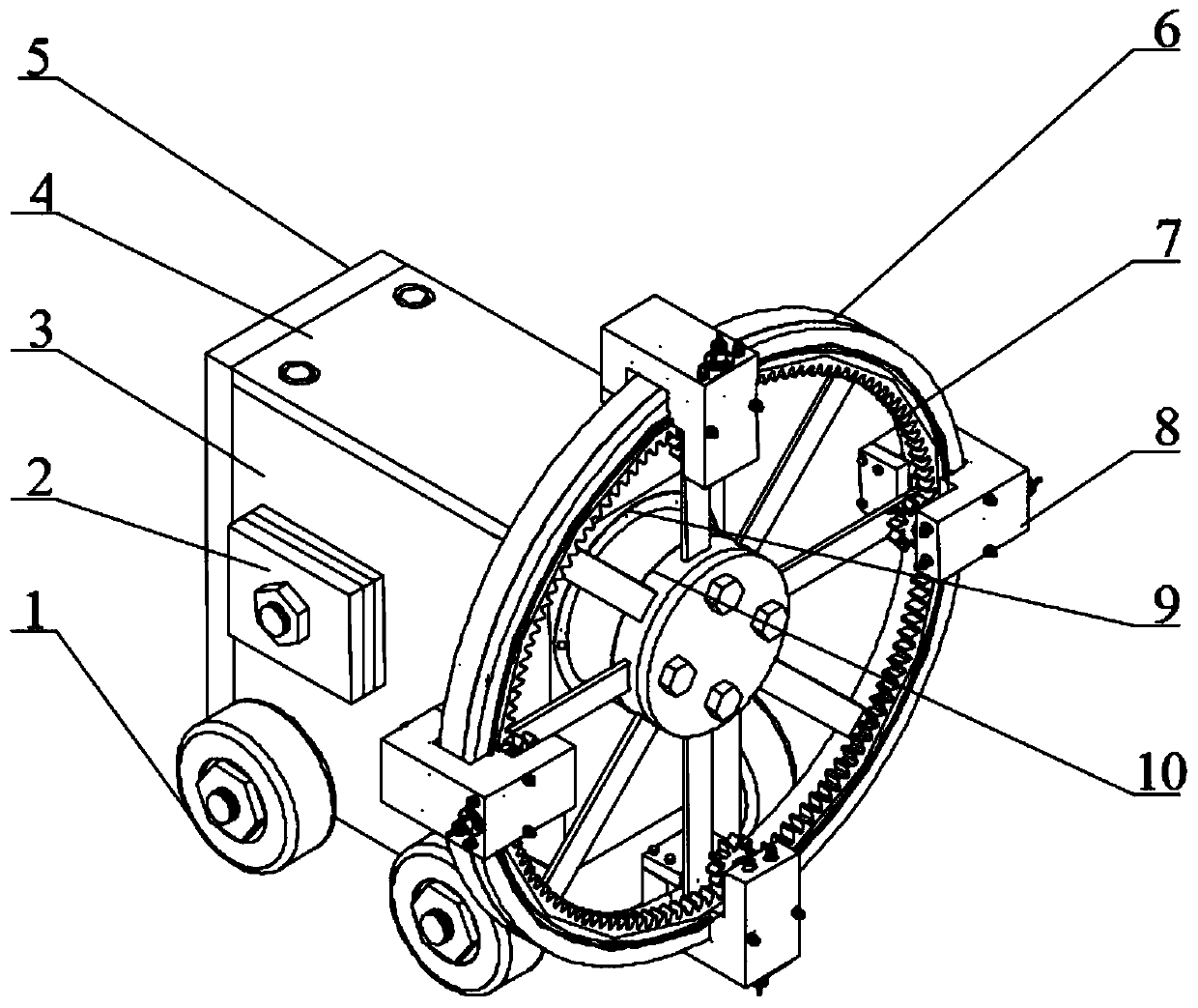

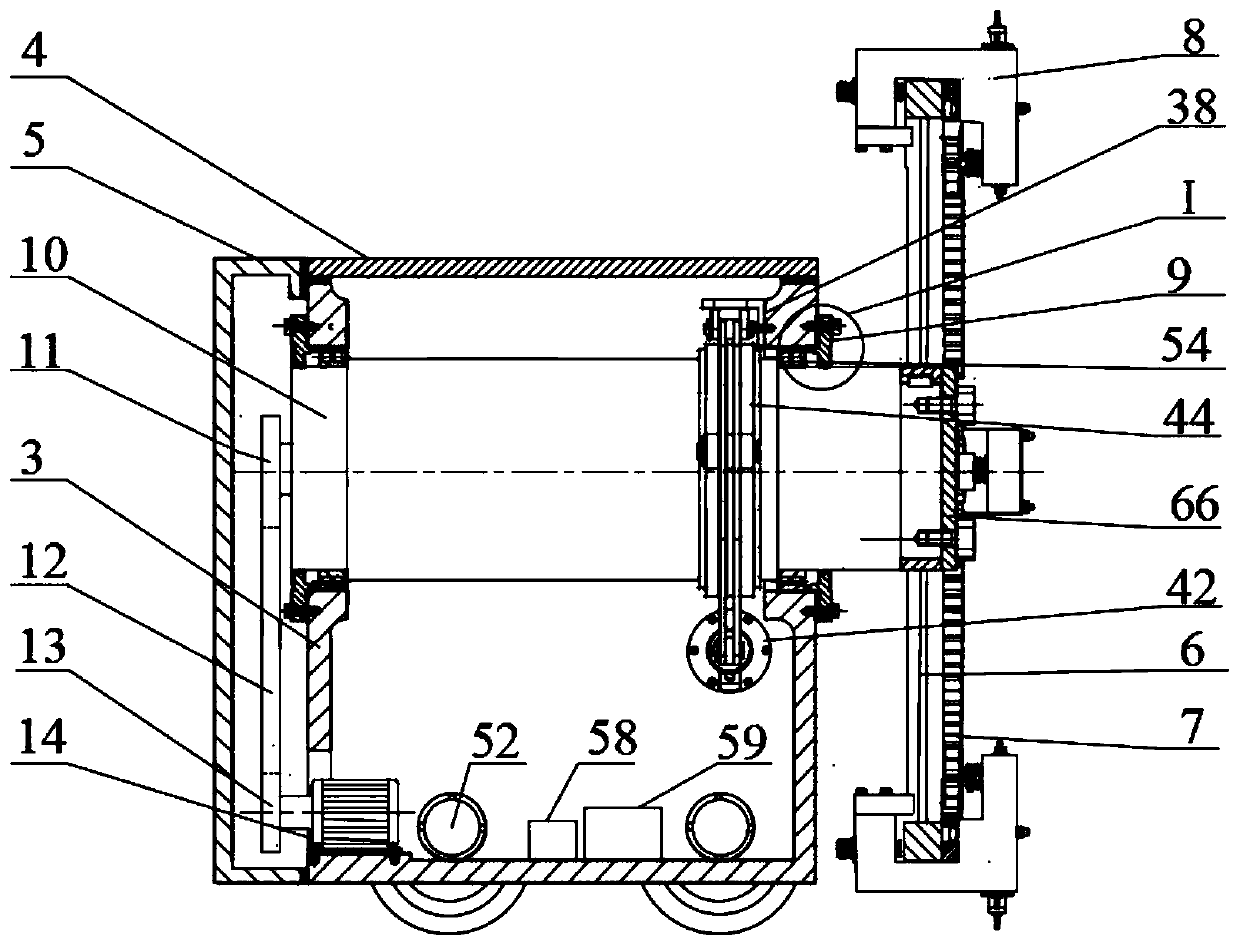

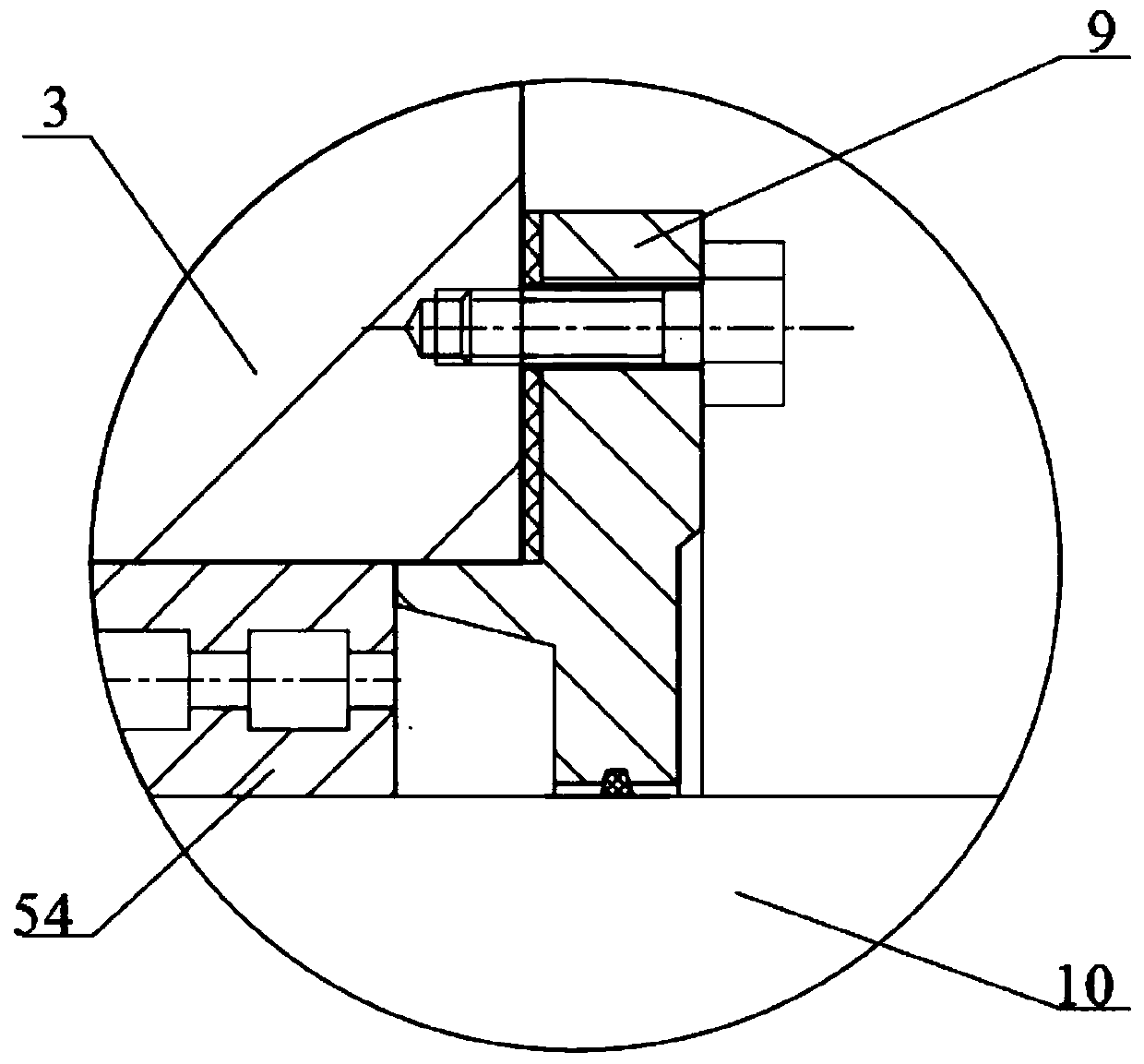

[0047] The invention provides a demolition robot suitable for the residual refractory bricks of the rotary kiln. The invention is suitable for the demolition of the residual refractory bricks of the rotary kiln. system and control system.

[0048] The load-carrying mobile system includes wheels 1, counterweight 2, lower vehicle body 3, upper cover plate 4, drive motor 52, second bearing end cover 53 and tapered roller bearing 64, upper cover plate 4 and lower vehicle body 3 pass through the submerged Head bolts are fixedly connected, and a soft gasket is installed between the upper cover plate 4 and the lower car body 3. The main function of the soft gasket is to prevent dust from entering the car body. The rotating shaft of the driving motor 52 passes through the tapered roller bearing 64, the second Two bearing end caps 53, the mounting hole on the wheel locking clamp block 50 and the wheel 1, the key provided on the keyway provided with the driving motor 52 rotating shaft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com