Maintenance equipment for heat exchange equipment in chemical plant

A technology for heat exchange equipment and maintenance equipment, applied in the direction of lighting and heating equipment, non-rotating equipment cleaning, cleaning heat transfer devices, etc., to achieve the effect of smooth heat transfer tubes and reduce pollution

Pending Publication Date: 2022-06-10

窦全

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]In order to overcome the manual cleaning method of using high-pressure water guns to wash down the chemical residues, not only a large amount of water is needed to clean them, but also the rinsed water and The mixture of compounds makes the water polluted. When the water flows into the heat transfer tube of the heat exchanger when the water flows into it, the dirt condenses together. And because of the high pressure of the incoming water, the splashed dirt will cause harm to the staff. The invention provides a maintenance equipment for heat exchange equipment in chemical plants.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

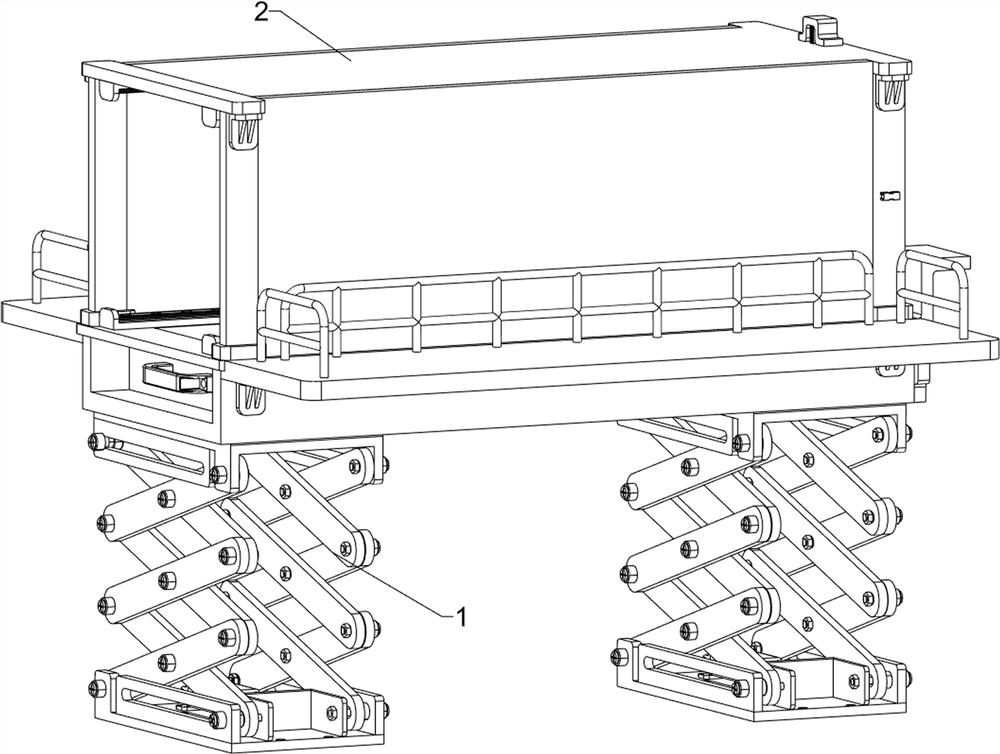

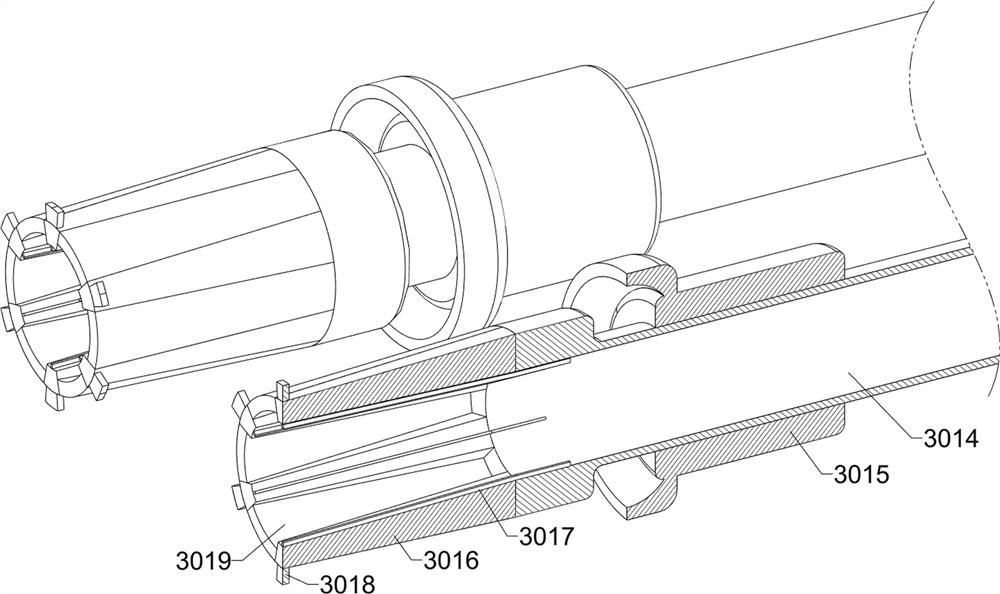

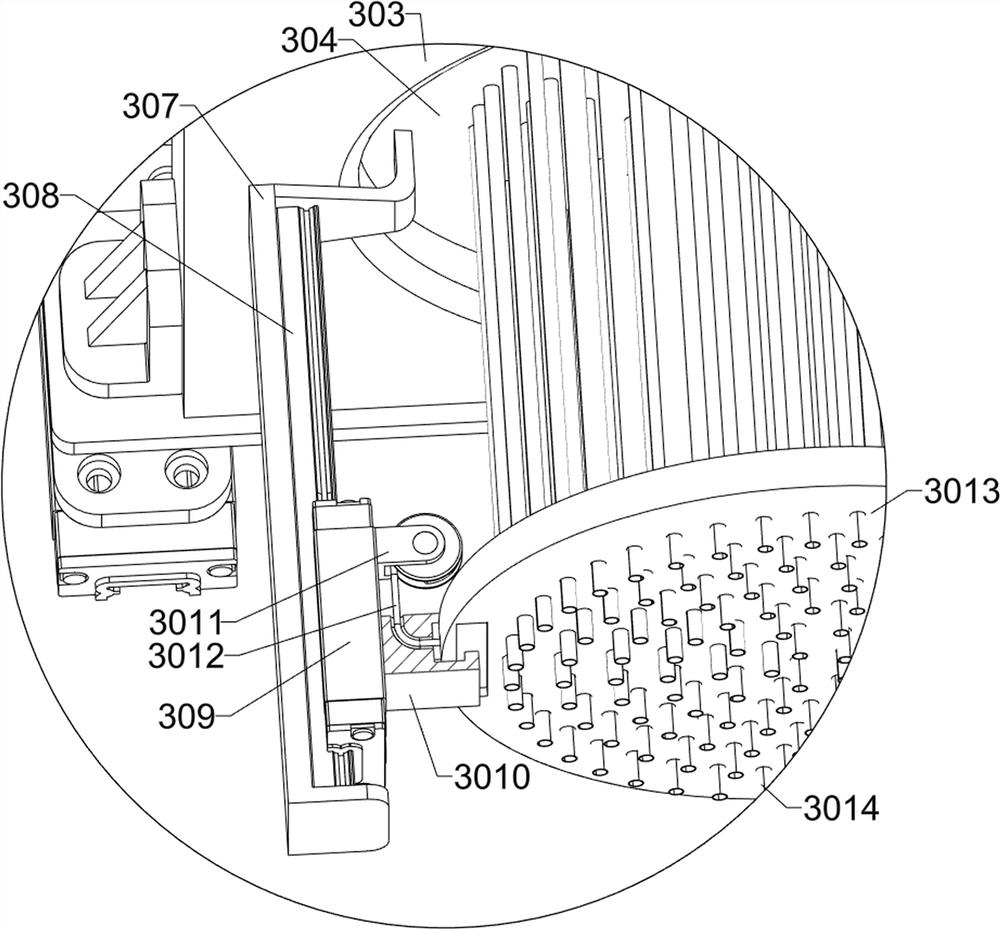

The invention relates to the technical field of chemical equipment, in particular to maintenance equipment for heat exchange equipment of a chemical plant. The technical problems that chemical residues are scoured down, when water flows into a person when a heat transfer pipe of a heat exchanger is cleaned, due to the fact that dirt is condensed together, when the person is subjected to impulsive force, the dirt which is splashed out can be splashed to the body of the person, and due to the fact that the introduced water is high in pressure, the splashed dirt can injure the worker are solved. According to the technical scheme, the maintenance equipment for the heat exchange equipment of the chemical plant comprises a lifting system, a transportation system and the like; a conveying system used for conveying the inner pipe cleaning system and the surface cleaning system is installed on the upper portion of the lifting system. According to the invention, the disassembly and maintenance of the heat exchanger are realized, the twisting force required by the disassembly of the heat exchanger is utilized, and chemical residues are firstly damaged and then washed in a twisting manner.

Description

technical field [0001] The invention relates to the technical field of chemical equipment, in particular to maintenance equipment for heat exchange equipment in chemical plants. Background technique [0002] A heat exchanger is a device that transfers part of the heat of a hot fluid to a cold fluid, also known as a heat exchanger. Heat exchangers play an important role in chemical, petroleum, power, food and many other industrial productions. In chemical production, heat exchangers can be used as heaters, coolers, condensers, evaporators and reboilers, etc., and are widely used , but in the process of working in a chemical plant, some compounds will solidify or crystallize during the heat exchange process of the compound, and it will be blocked after long-term use, making the heat exchanger unable to work, and regular maintenance of the heat exchanger is required; In the prior art, the cleaning method of manual use of high-pressure water guns is used to wash down the chemi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F28G13/00F28G1/08F28G9/00F28G15/00F28G15/02F28G15/04

CPCF28G13/00F28G9/00F28G1/08F28G15/02F28G15/04F28G15/00F28G2015/006

Inventor 窦全

Owner 窦全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com