Underwater concrete template stripping device and method

A technology for underwater concrete and concrete surfaces, which is applied in the processing of formwork, the preparation of building components on site, construction, etc., can solve the problems of easily damaged concrete surfaces, high construction strength, and slow formwork removal speed, etc. Safe construction, fast demolition speed, and the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

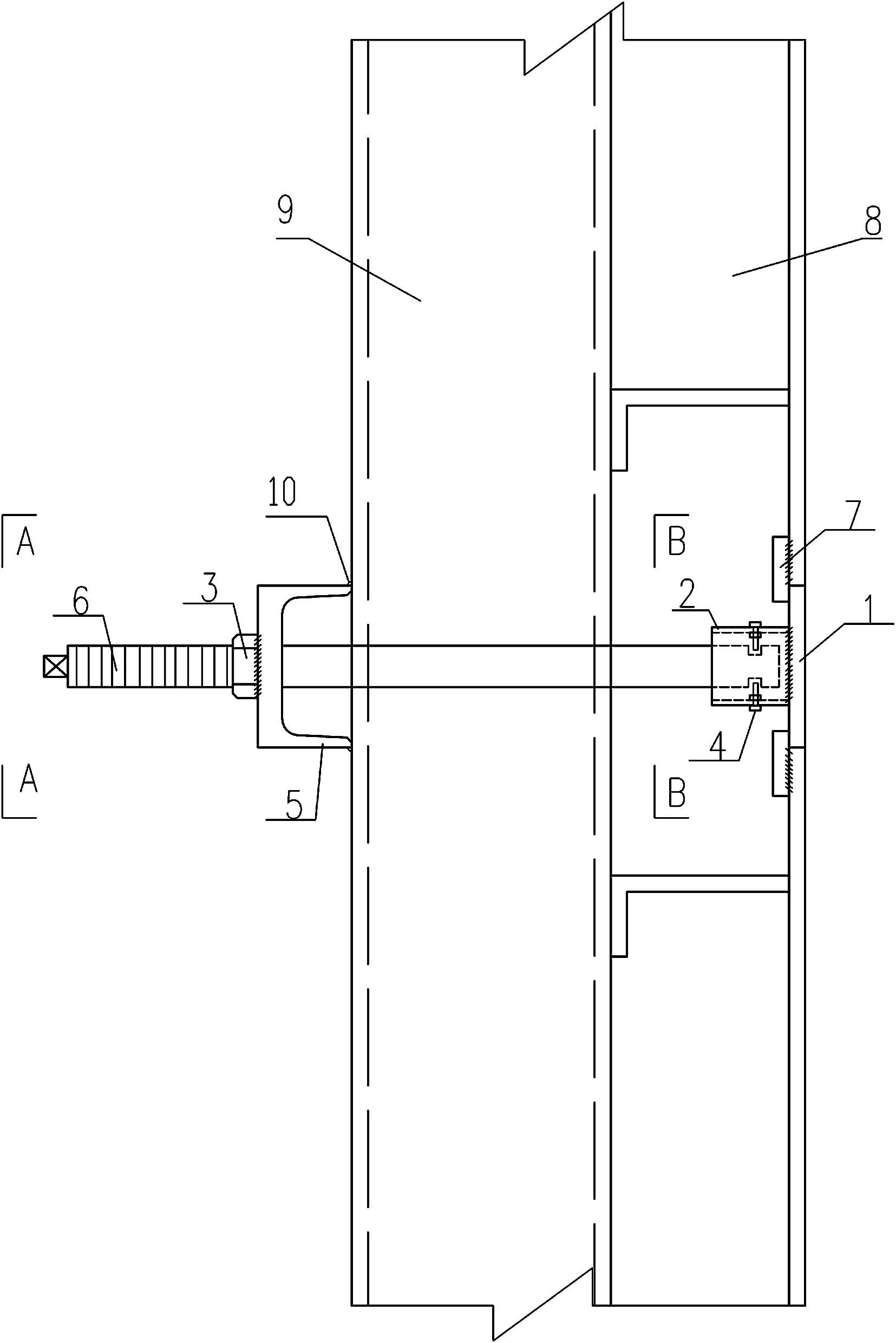

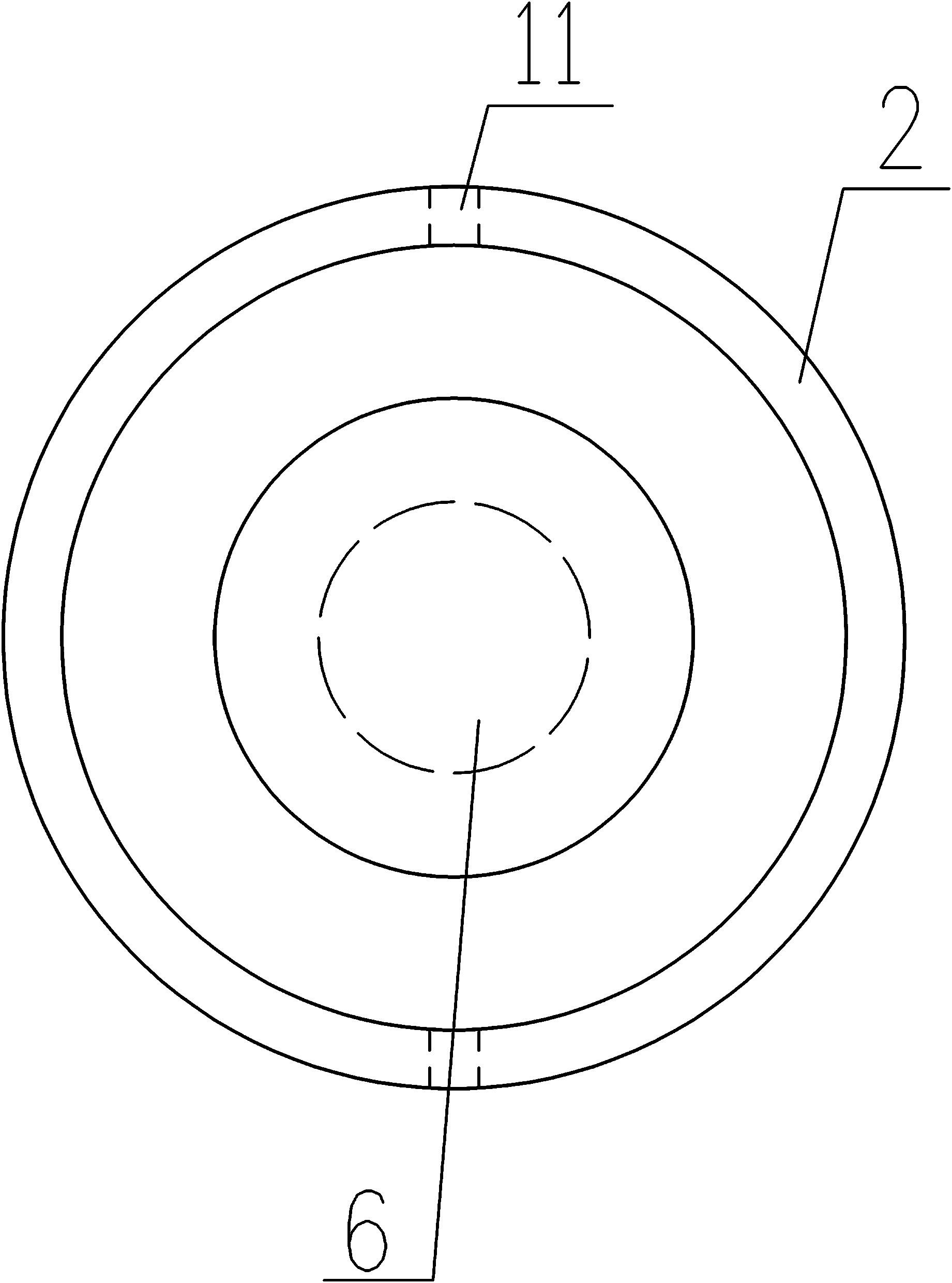

[0024] Such as Figure 1 ~ Figure 3 Among them, an underwater concrete formwork removal device includes an integral formwork 8, on which a screw rod 6 is installed through a base 5, one end of the screw rod 6 is movably connected to a steel sleeve 2, and the steel sleeve 2 is fixed to a steel panel 1 connect;

[0025] The steel panel 1 is embedded and installed on the working surface of the integral formwork 8 , and the joints are generally ensured to be as small as possible, and the working surface of the steel panel 1 is flush with the working surface of the integral formwork 8 .

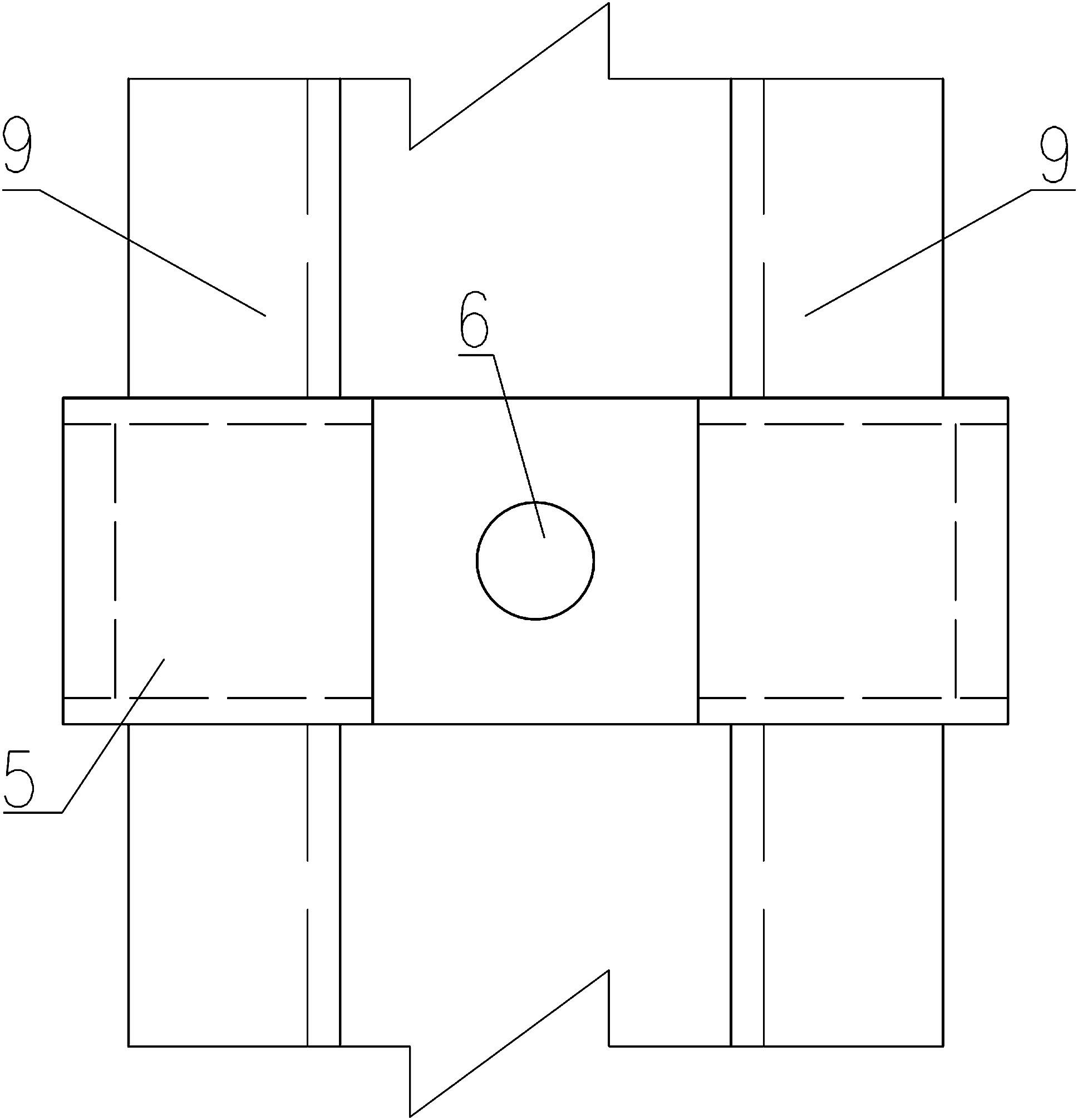

[0026] The base 5 is welded to the purlins 9 on both sides, and the base 5 is provided with internal threads.

[0027] The screw rod 6 is provided with an external thread, one end of the screw rod 6 is provided with a clamping head, and the other end is provided with an annular groove.

[0028] The steel sleeve 2 is provided with positioning pins or bolts 4 matching the annular grooves.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com