Fabricated soil nail wall and soil nail wall construction and dismounting methods

A construction method, the technology of soil nailing walls, applied in excavation, artificial islands, sheet pile walls, etc., can solve the problems of slow construction speed and long construction process of soil nailing walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

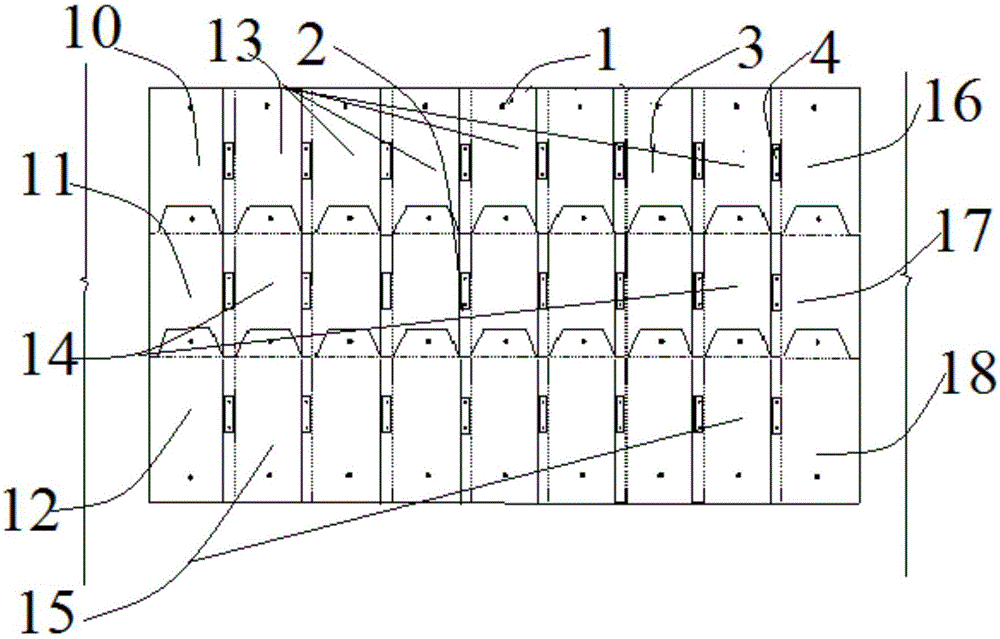

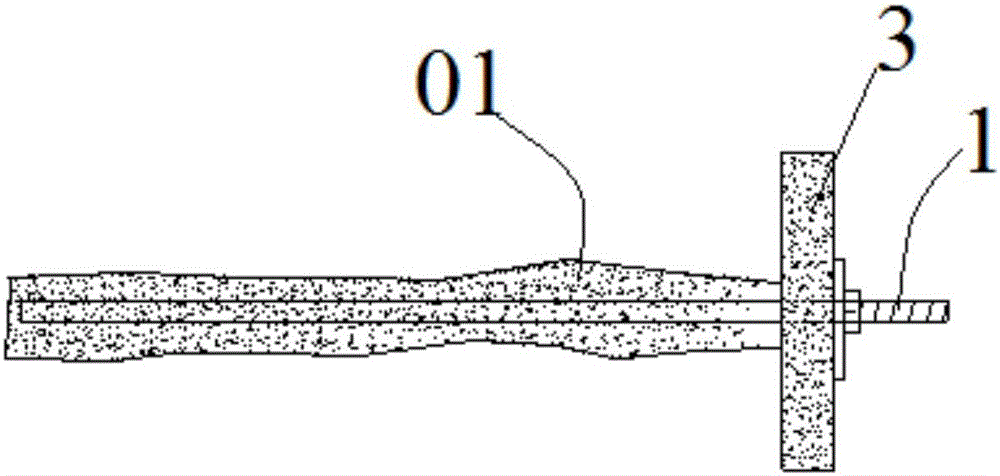

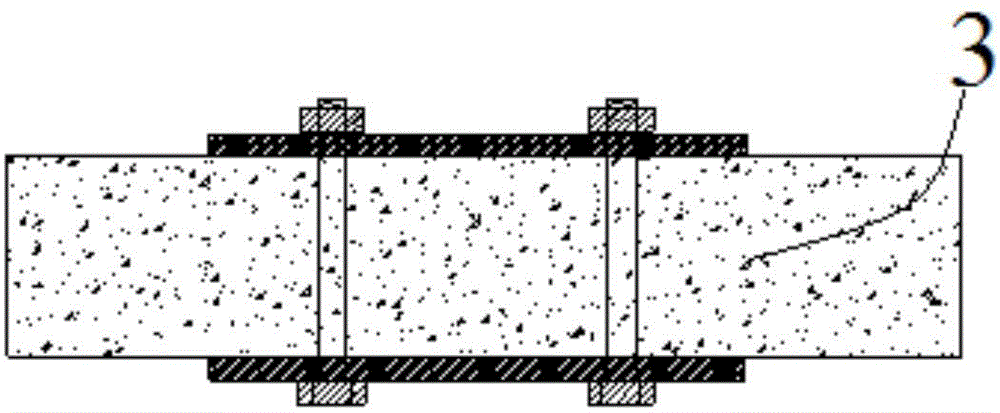

[0139] see figure 1 , figure 2 and Figure 5 As shown, the embodiment of the present invention is an assembled soil nail wall, which can be applied to slope support and foundation pit excavation support engineering. The soil nail wall includes: soil nail 1, wall body 2 and fasteners One end of the soil nail is fixed in the soil of the foundation pit slope or side slope, the other end of the soil nail is suspended outside the soil as a free section of the soil nail, and the wall includes a plurality of prefabricated panels 3, The prefabricated board 3 is provided with a connection structure 4 and soil nail holes 5, and the plurality of prefabricated boards 3 are connected horizontally and vertically to form the wall 2 through the connection structure through the connecting piece, and the wall 2 passes through the The soil nail hole 5 is inserted and hung on the soil nail 1 from the other end (free section) of the soil nail 1, and the wall 2 is fixedly connected to the soil n...

Embodiment 2

[0149] In order to clearly describe the embodiment of the present invention, some elements used in this embodiment are now described: No. 1 to No. 9 prefabricated panels mentioned below correspond to figure 1 and Figures 3 to 13 For the first prefabricated board to the ninth prefabricated board mentioned, please refer to the corresponding drawings.

[0150] see Figure 25 As shown, the embodiment of the present invention is a method for constructing a prefabricated soil nail wall, including steps: S1, installing one end of the soil nail in the soil body, and the other end is suspended outside the soil; S2, fixing the prefabricated plate to the The soil is nailed, and the adjacent prefabricated panels are fixed horizontally and vertically into a whole with connectors.

[0151] An embodiment of the present invention is a construction method for a soil nail wall, comprising: installing one end of the soil nail in the soil body, and setting the other end suspended outside the s...

Embodiment 3

[0160] An embodiment of the present invention is a method for dismantling a prefabricated soil nail wall, which includes: first removing the connecting parts between the prefabricated panels; the connecting parts need to be removed group by group from right to left; The fasteners between the slab and the soil nails; the fasteners need to be removed according to the number of prefabricated slabs, and the fasteners on one prefabricated slab are removed, and then the fasteners on the next prefabricated slab are removed; The prefabricated panels are taken out from the soil nails and recycled; the above steps are repeated until all the soil nail walls are removed.

[0161] The embodiment of the present invention provides a prefabricated soil nailing wall removal method. Since the soil nailing wall adopts a prefabricated detachable structure, it is only necessary to remove the connectors to realize the overall demolition of the soil nailing wall. The construction materials of the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com