Construction method for dismounting concrete support of fabricated subway station

A technology for subway stations and construction methods, which is applied in the fields of earthwork drilling, artificial islands, underground chambers, etc., can solve the problems of low safety, low efficiency, long construction period, etc., and achieve the effect of simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

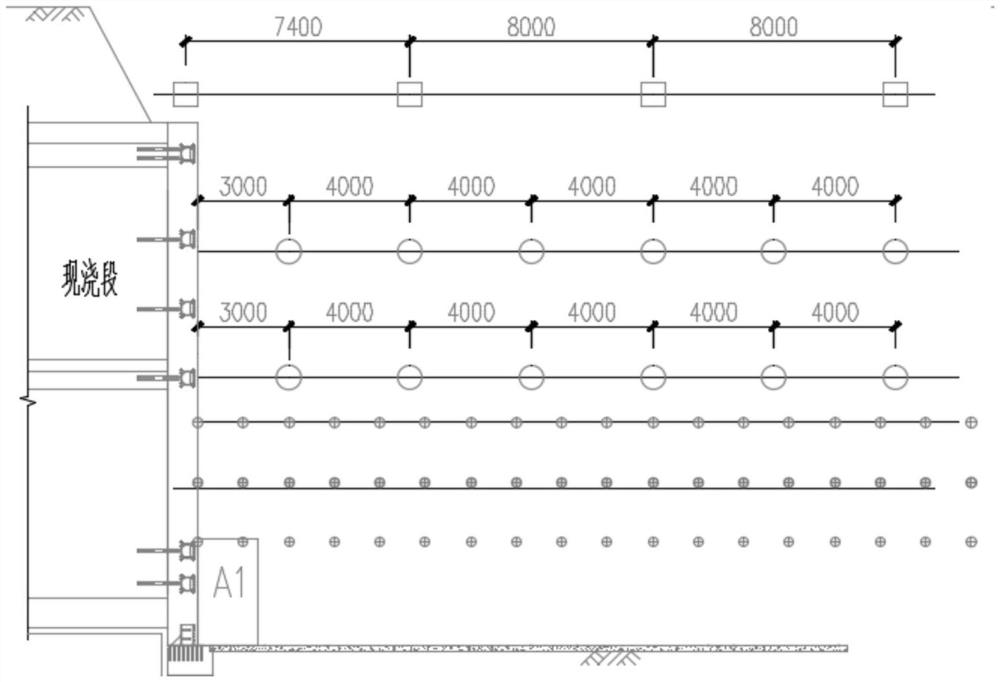

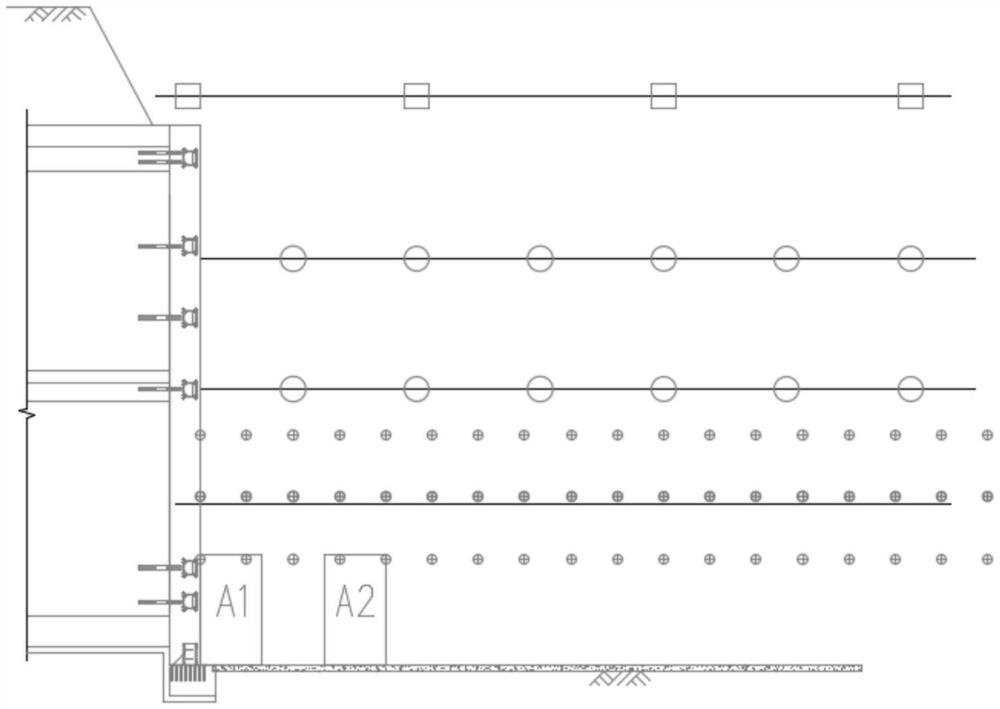

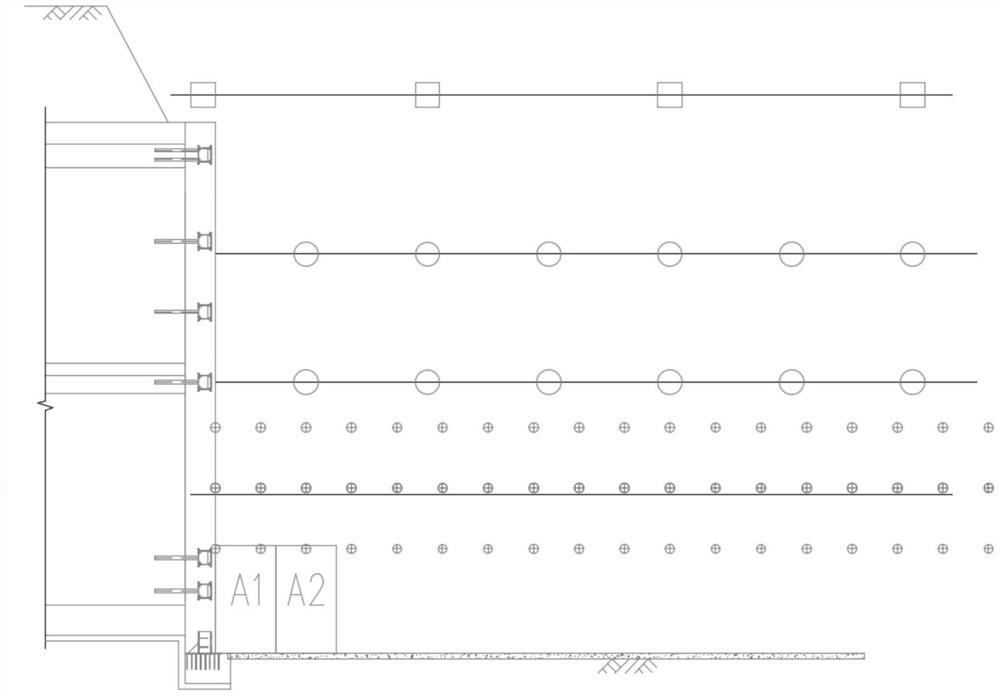

[0044] This embodiment is applied to a prefabricated subway station. In this embodiment, the foundation pit and roadway are sequentially composed of a 42m long cast-in-place section, a 148m long assembly section and a 28m long cast-in-place section. The geology of the foundation pit and roadway is mainly plain fill, silty clay, cohesive soil gravel sand, strongly weathered tuff, moderately weathered tuff and slightly weathered tuff, and the foundation pit and roadway are mainly located in silty clay and cohesive soil gravel In sand, the base is located in strong and medium weathered tuff, and the anti-floating water level elevation is 12m.

[0045] The cross-sectional size of the concrete support to be removed is 1000mm×800mm, the length is 22m, and the weight of the concrete support is about 44t. The concrete support is removed in the foundation pit and roadway from the construction to the assembly stage.

[0046] Specifically, this embodiment discloses a construction method f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com