Method for restraining warping of asymmetric printed circuit board

A printed circuit board and warpage suppression technology, which is applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of reducing production efficiency, circuit board warping rebound, increasing production cycle, etc., and achieves the improvement of production pass rate , Inhibit warpage, reduce production cost and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

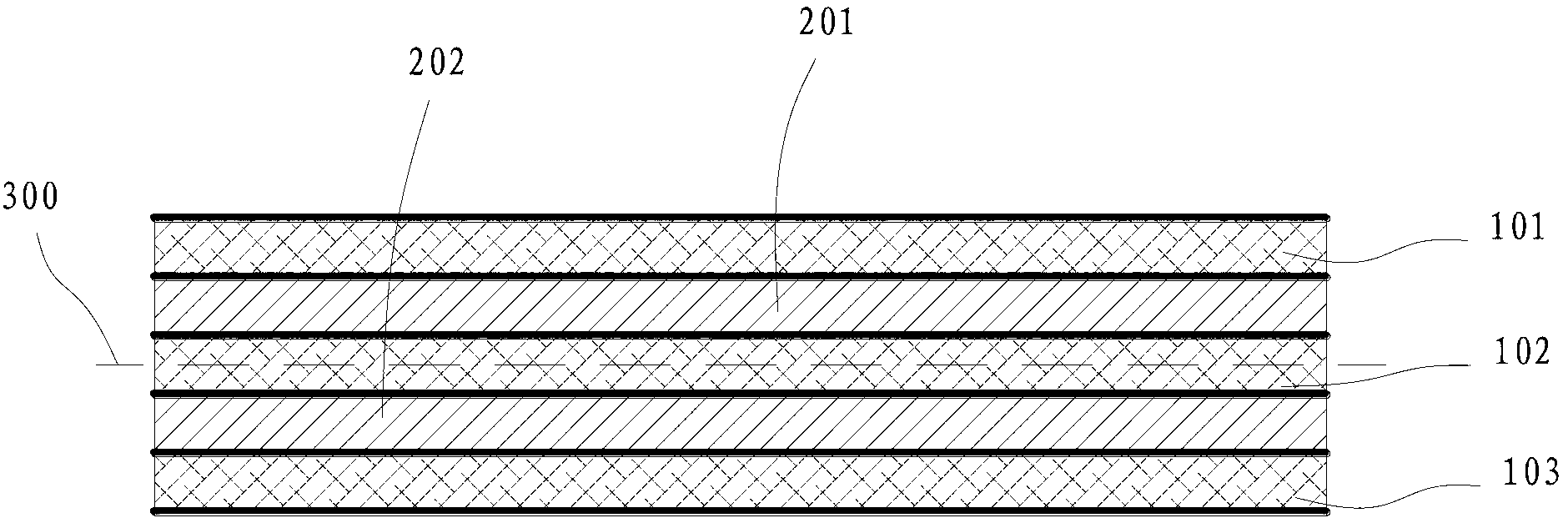

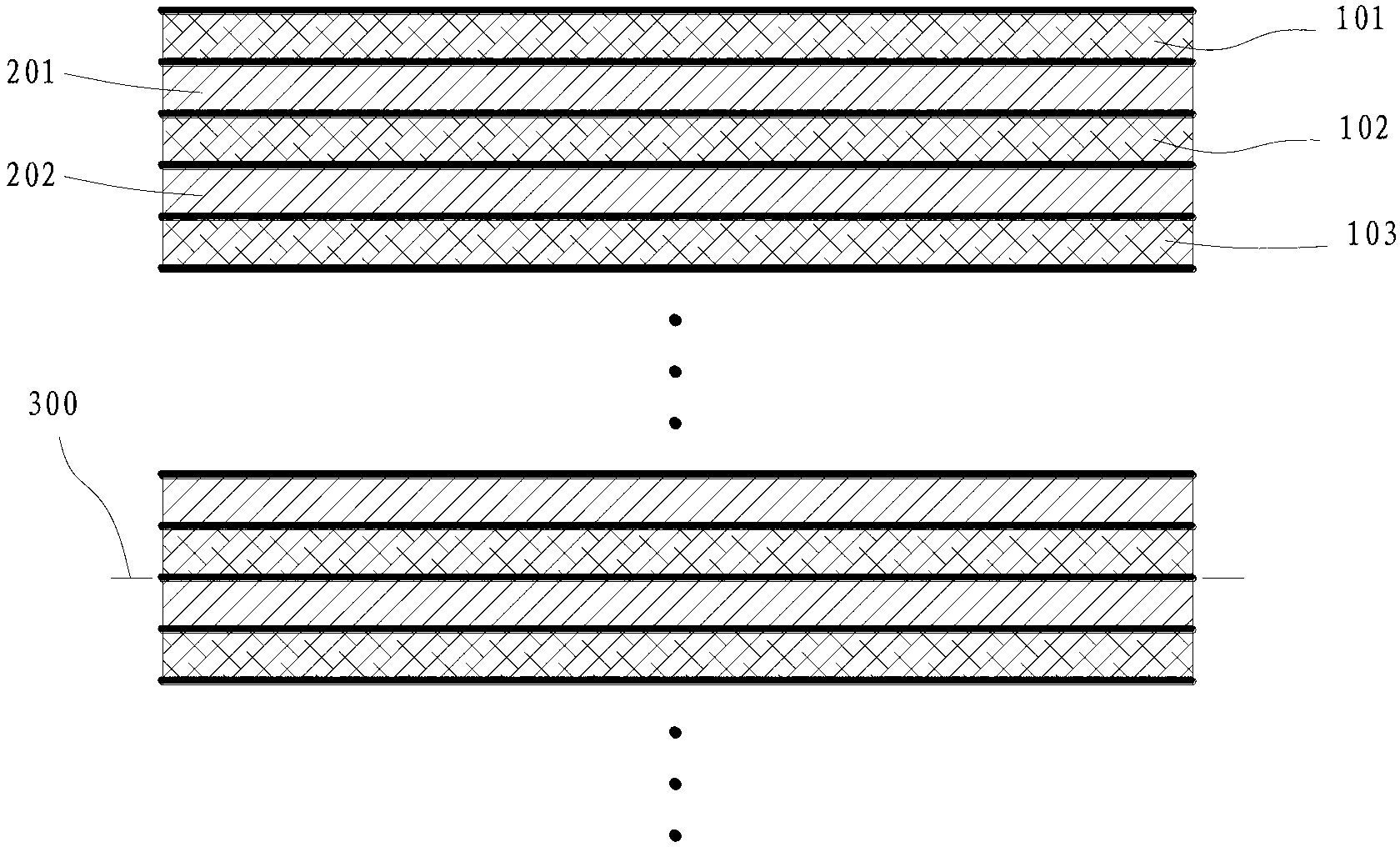

[0055] Such as image 3 As shown, this embodiment takes a six-layer printed circuit board as the design object. In this embodiment, the thickness H of the first layer core board 201 1 =0.546mm, the thickness H of the second core board 202 2 =0.136mm, the residual copper rate of each layer is between 40% and 50%, and the total plate thickness is required to be controlled at 1.4mm±10%.

[0056] Since the two layers on the outside of the printed circuit board are prepreg 100, so or due to H 1 >H 2 , and the first-layer core board 201 and the second-layer core board 202 serve as the core boards at corresponding positions on both sides of the symmetrical mirror surface 300 , so choose In this formula i=1, n=6, so Thanks to K H >1.6, so K h The value range of is [2.5,4]. In the printed circuit board of this embodiment, the first layer of prepreg 101 and the third layer of prepreg 103 are used as the prepreg 100 at the corresponding positions on both sides of the symmetri...

Embodiment 2

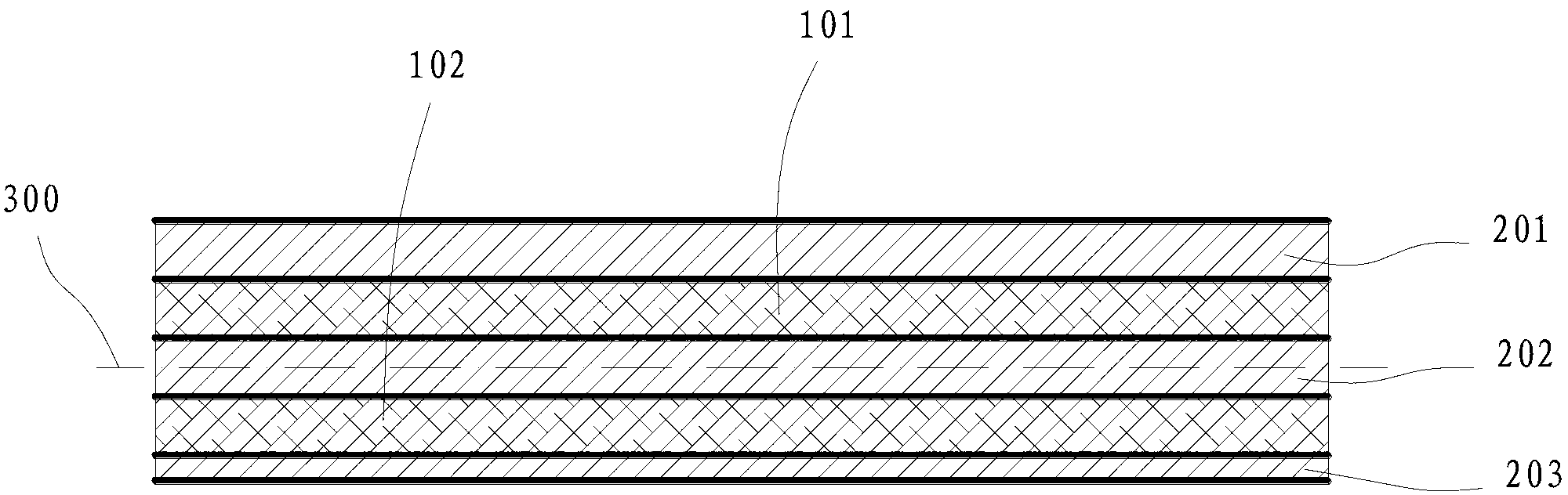

[0058] Such as Figure 4 As shown, this embodiment takes a six-layer printed circuit board as the design object. In this embodiment, the thickness H of the first layer core board 201 1 =0.746mm, the thickness H of the third core board 203 2 =0.136mm, the residual copper ratio of each layer is about 50%, and the total board thickness is required to be controlled at 2.2mm±10%.

[0059] Since the two layers on the outside of the printed circuit board are the core board 200, so or due to H 1 >H 3 , and the first-layer core board 201 and the third-layer core board 203 serve as the core boards at corresponding positions on both sides of the symmetrical mirror surface 300 , so choose In this formula i=1, n=6, so Thanks to K H >1.6, so K h The value range of is [2.5,4]. In the printed circuit board of this embodiment, the first layer of prepreg 101 and the second layer of prepreg 102 are used as prepregs at corresponding positions on both sides of the symmetrical mirror su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com