Method and system for continuously producing aluminium/stainless-steel compound material

A composite material and stainless steel technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of low thickness accuracy of aluminum/stainless steel composite materials, difficult matching of punching gaps, and large overall dimensional deviation, so as to shorten the production cycle, High yield and the effect of solving deformation and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation manners of the present invention will be described in more detail below in conjunction with the accompanying drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

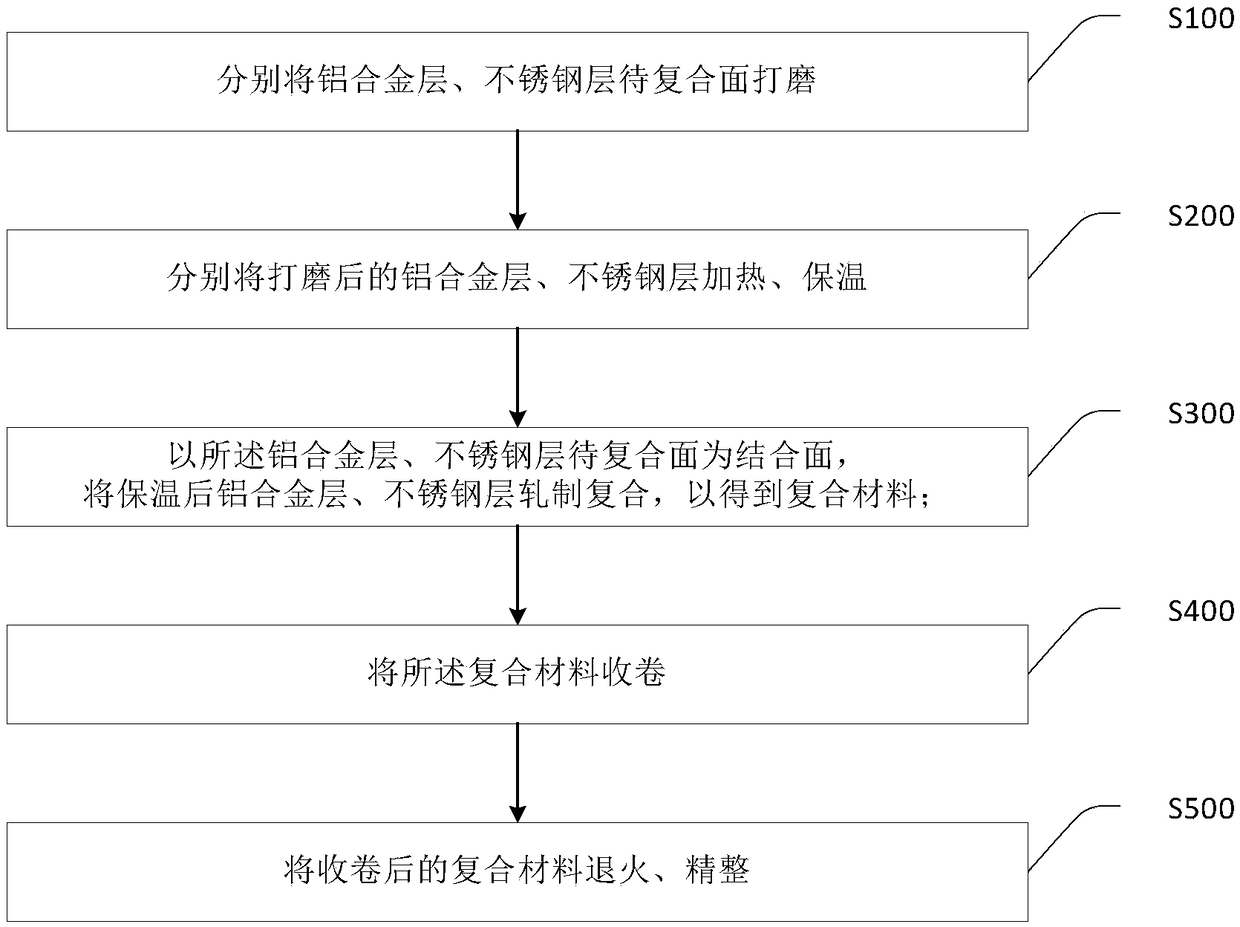

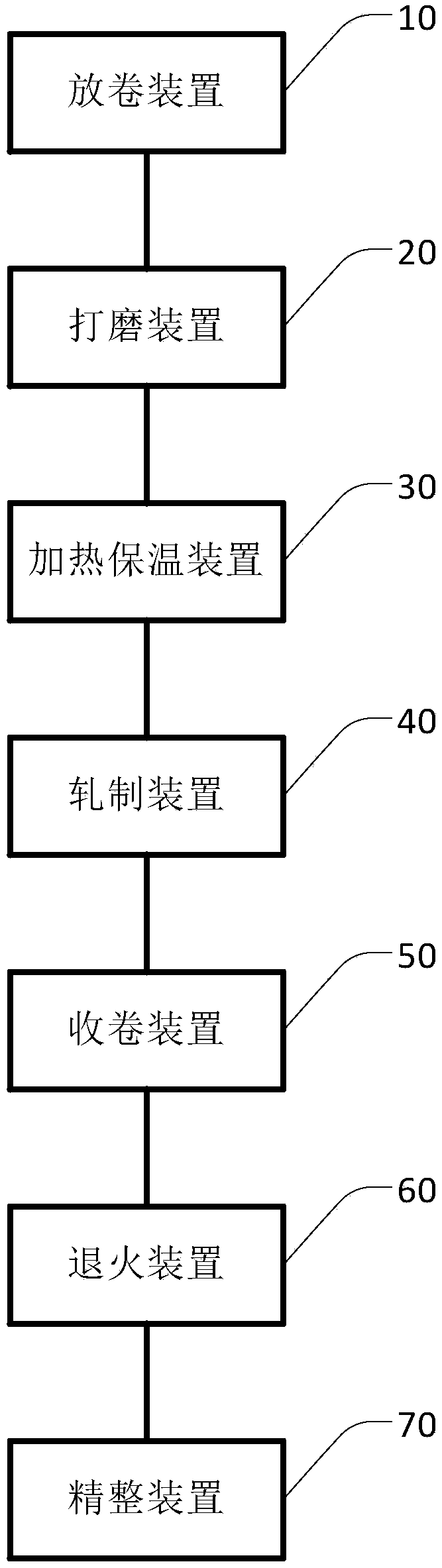

[0059] In the embodiment of the method for continuously producing aluminum / stainless steel composite materials provided by the present invention, the produced aluminum alloy-stainless steel composite materials are mainly used for making cookware. Such as figure 1 Shown is a flow chart of a method for continuously producing aluminum / stainless steel composite materials in an embodiment of the present invention. In this embodiment, the number of composite layers of aluminum alloy and stainless steel is not limited, and can be two layers, three layers or five layers,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com