Locating jig

A positioning jig and positioning hole technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reducing the production yield of finished products, poor positioning, damage to the protective film and frame, etc., and achieve the effect of improving efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

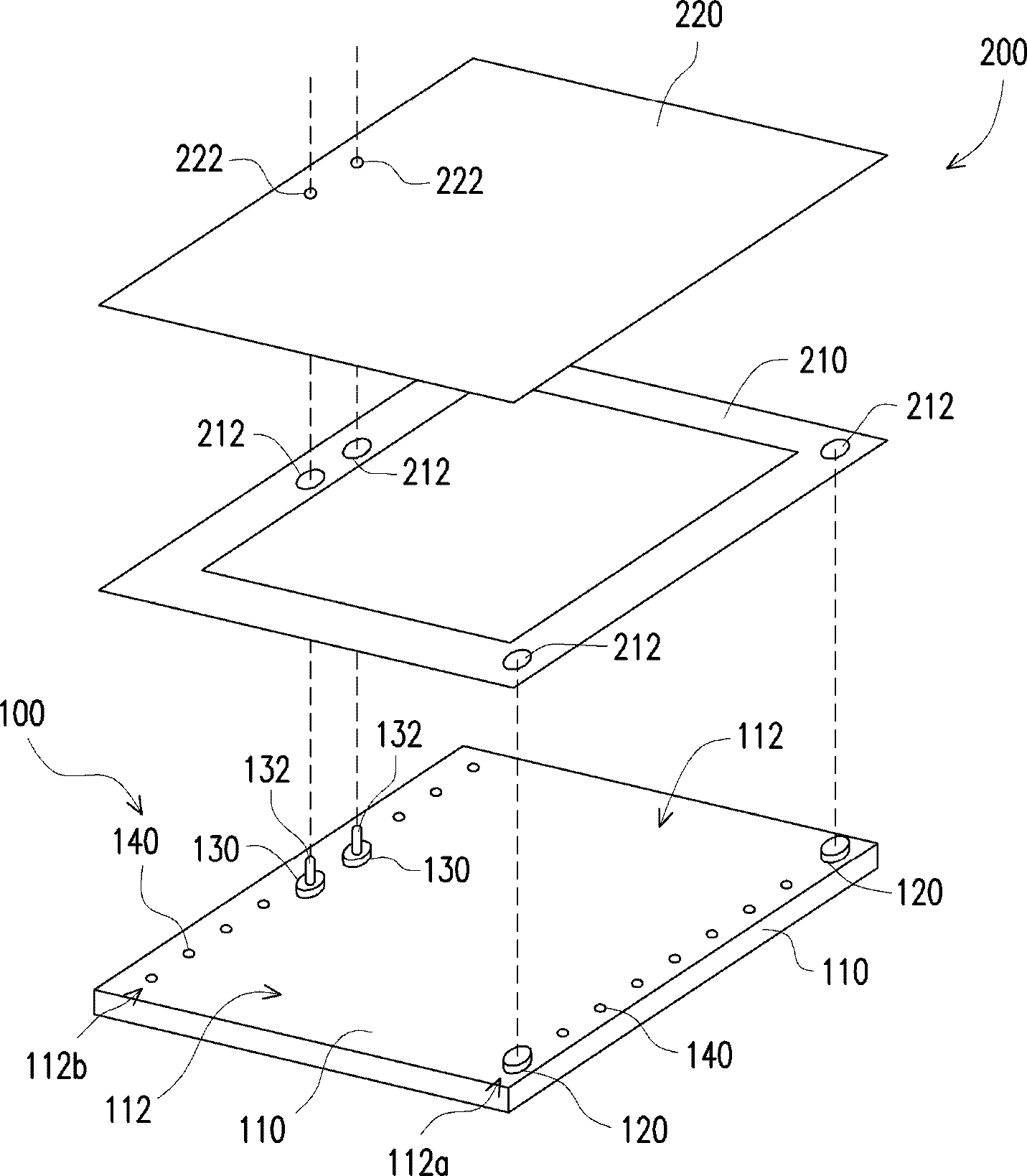

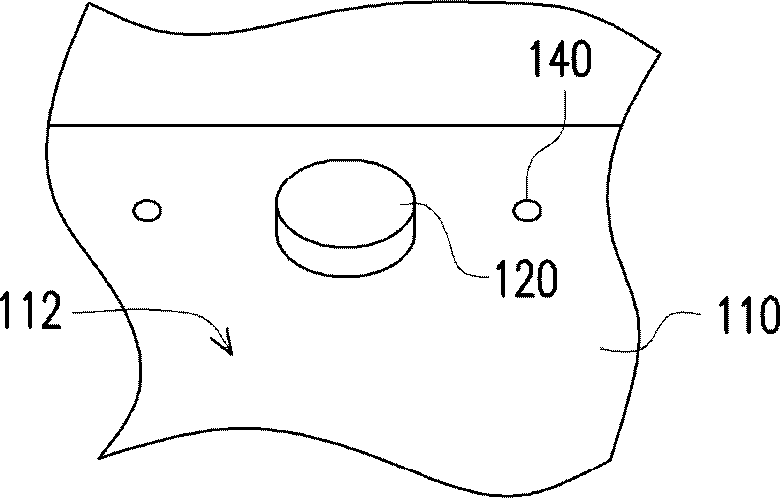

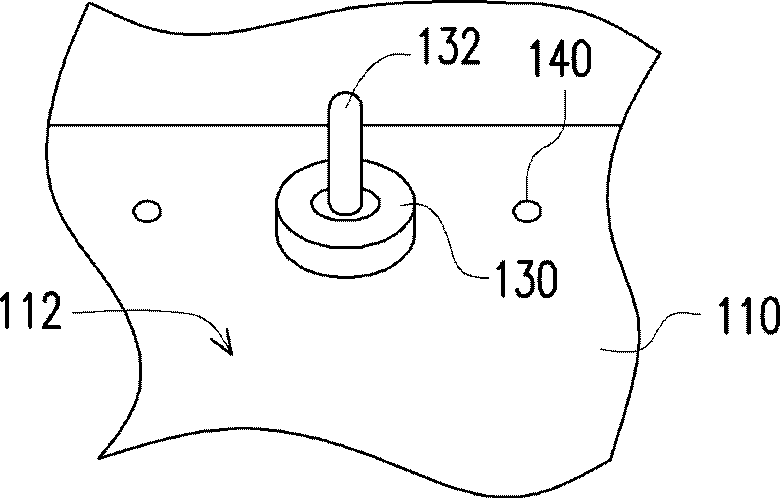

[0035] figure 1 It is an exploded schematic diagram of a positioning jig, a frame and a protective film according to an embodiment of the present invention. Please refer to figure 1 , the present invention proposes a positioning jig 100 suitable for positioning between a frame 210 and a protective film 220 of a flat panel display 200 . Wherein, the frame 210 has a plurality of first positioning holes 212 (four are shown), and the protective film 220 has a plurality of second positioning holes 222 (two are shown). The material of the protective film can be transparent materials such as acrylic and glass, and the material of the frame can be rubber. The flat panel display 200 can be a liquid crystal display, a plasma display, or an organic light emitting diode display. In this embodiment, the flat panel display 200 is a liquid crystal display. The positioning jig 100 includes a platform 110 , a plurality of first positioning seats 120 (two are shown), and a plurality of seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com