Low-temperature testing tank

A low-temperature test and channel steel technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as bending and deformation of the outer tank, reduce heat leakage, ensure overall strength, and reduce deformation volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0032] Specific implementations of the present invention, such as Figure 1 to Figure 6 shown.

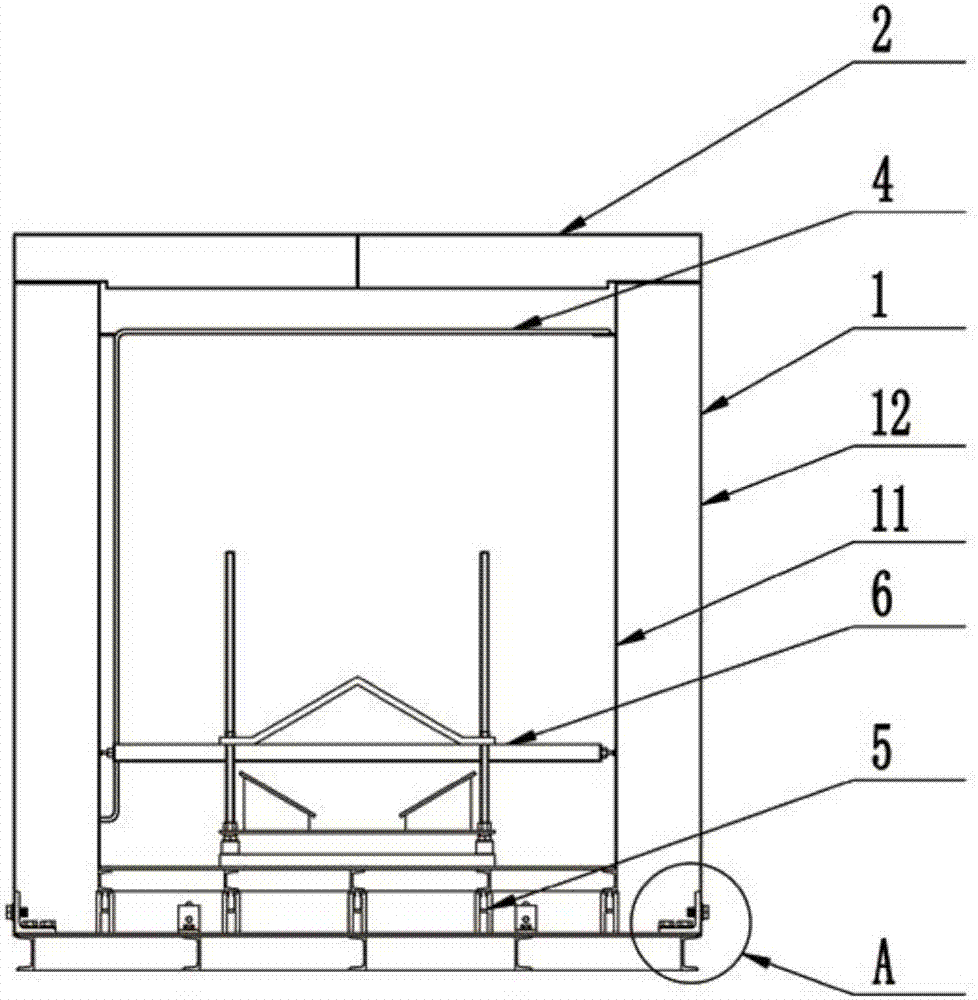

[0033] A low-temperature test tank, comprising a box body 1, a thermal insulation upper cover 2, a channel steel reinforcing rib 3, a spray device 4, an epoxy support rod 5 and a test piece fixing frame 6.

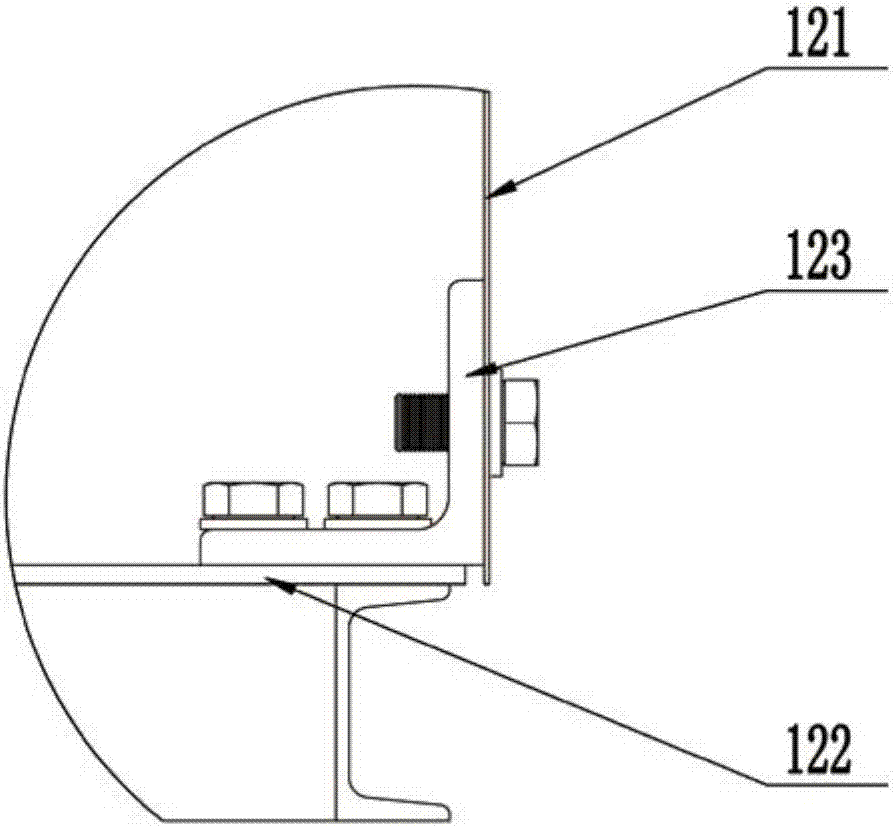

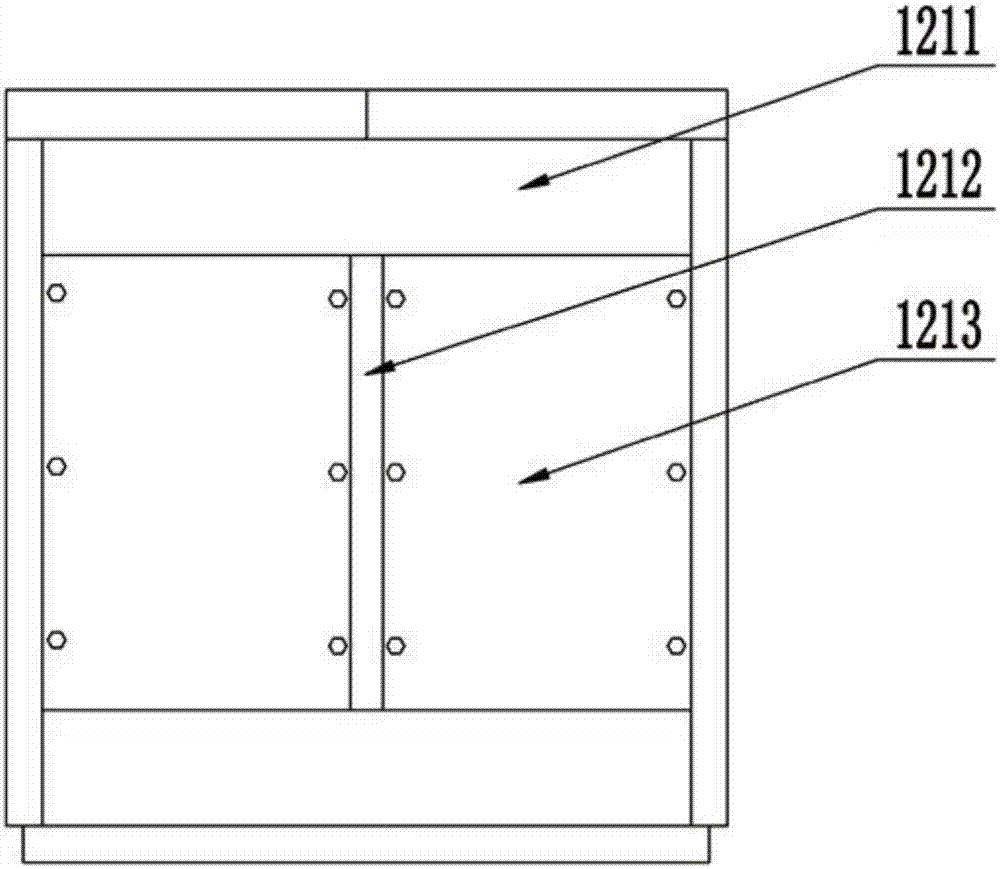

[0034] The box body 1 is opened upwards, and it includes an inner tank 11 and an outer tank 12 fitted inside and outside, and foam material is filled between the inner tank 11 and the outer tank 12 . The outer bladder 12 includes a side plate 121, a bottom plate 122 and a movable connector 123, the movable connector 123 is an L-shaped support seat, one end of the support seat is fixedly connected with the bottom plate 122, and the other end is provided with a chute extending vertically and passed through The bolt passing through the chute is movably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com