Rolling deoiling device

A pair of oil-absorbing roll technology, applied in the field of strip rolling, can solve problems such as abnormal operation, emulsion spots, product surface defects, etc., to ensure long-term stable operation, improve efficiency and effect, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

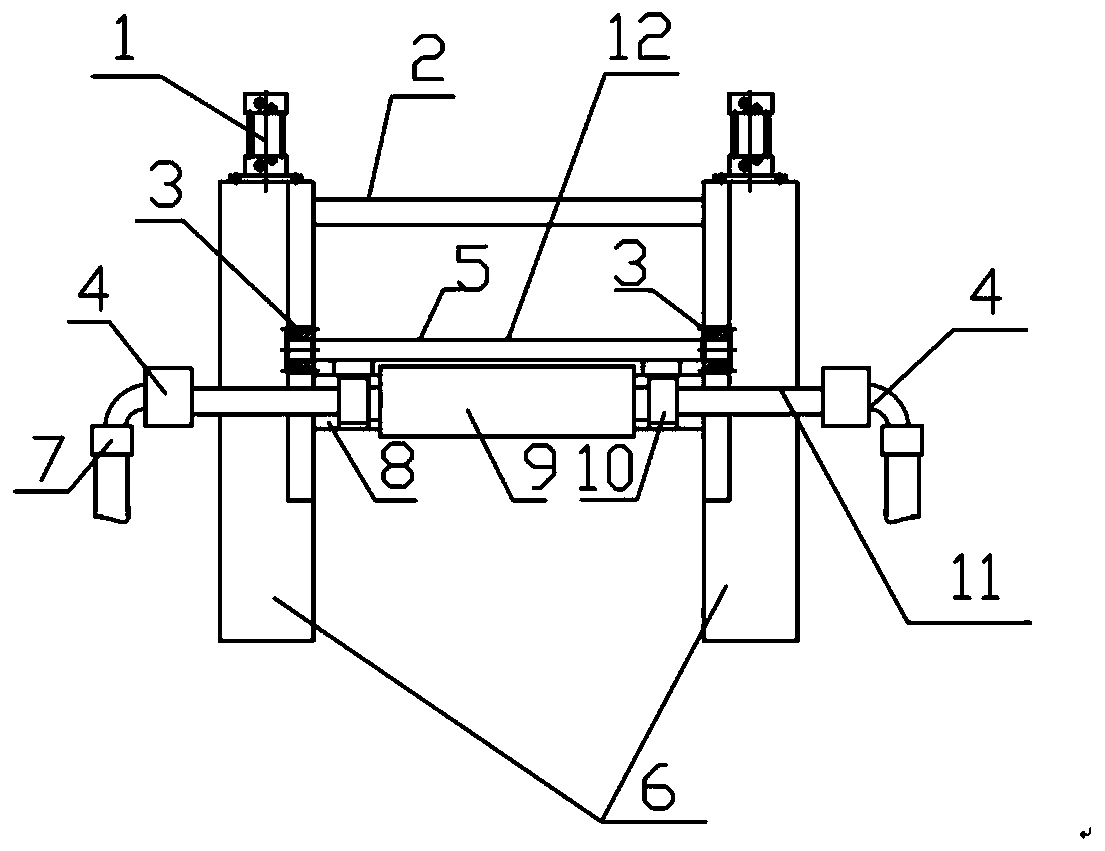

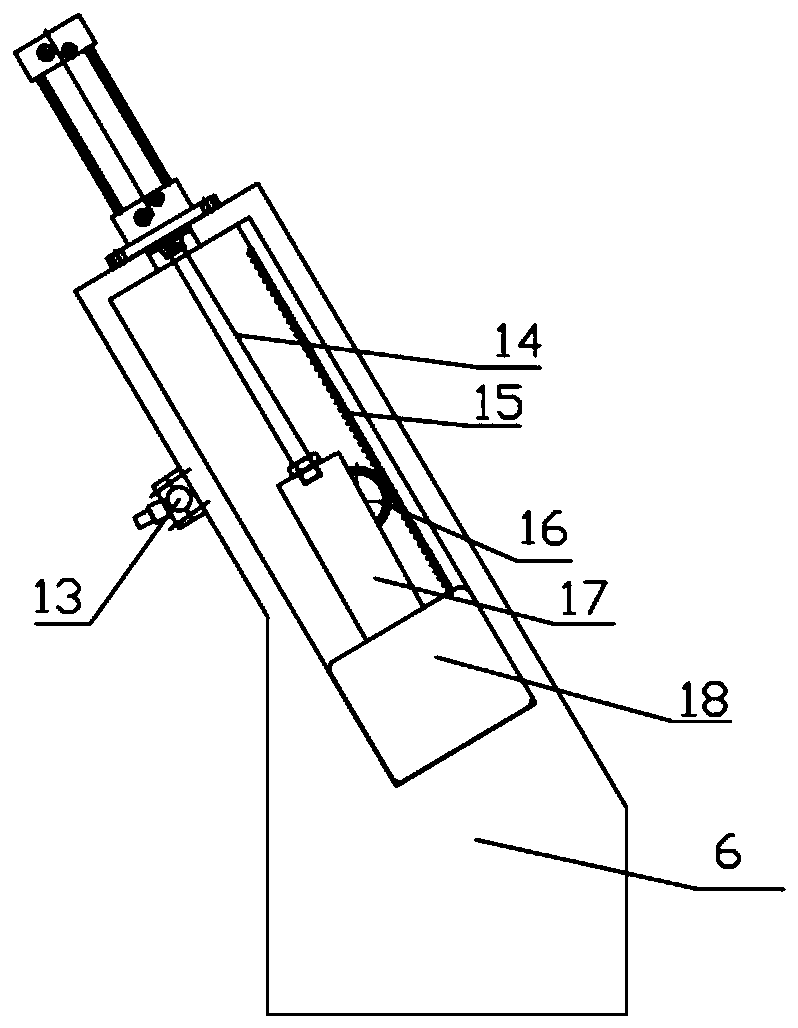

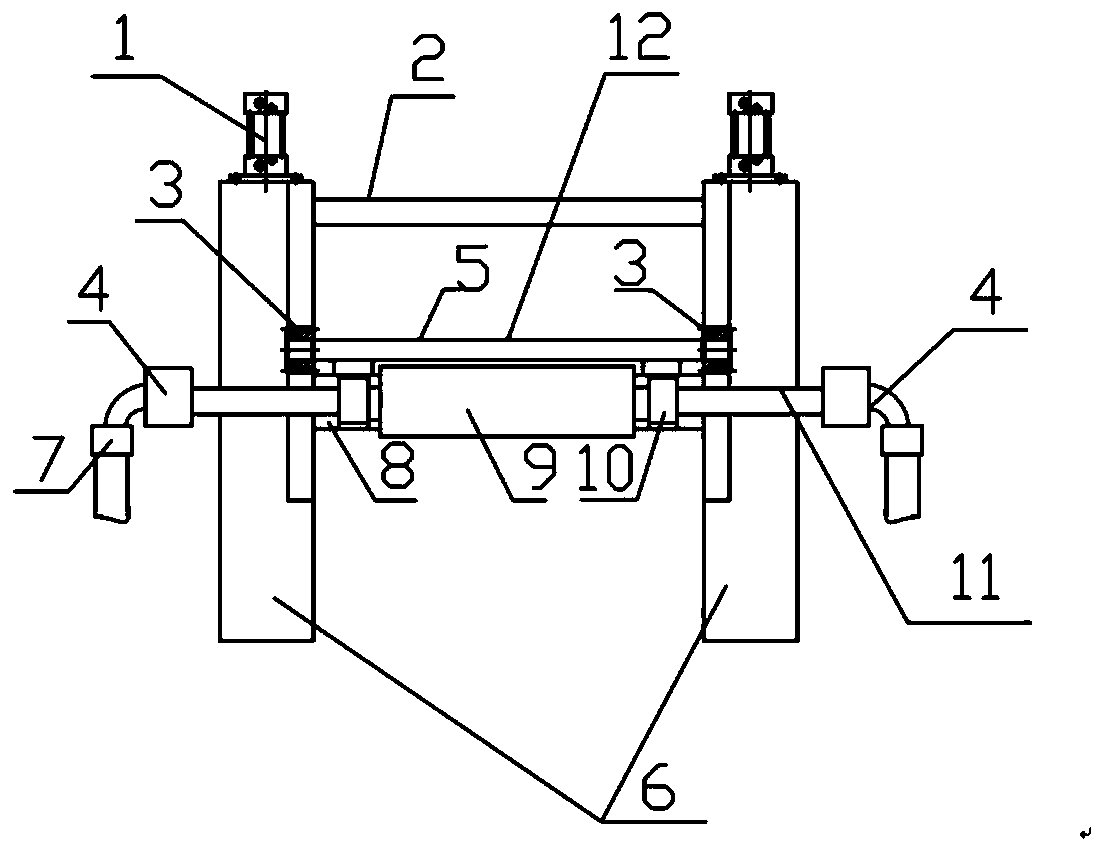

[0034] The device has two arches 6, on which other equipment components are installed and fixed, the core of which is the oil suction roller 9, which is fixed on the bottom plate 8 through the bearing seats 10 on both sides, and the bottom plate 8 passes through the sliding seats on both sides 18 is constrained in the chute on the archway 6, and the piston rod 14 of the lifting cylinder 1 installed on the archway is connected with the bottom plate slide seat 18 of the oil-suction roller through the connecting head 17; thus, under the promotion of the lifting cylinder, the oil-suction roller 9 With the sliding seat 18 to move up and down, at the same time, the sliding seats 18 on both sides are equipped with a synchronous gear 3, and the two synchronous gears 3 are connected by the synchronous connecting rod 5, and at the same time, synchronous racks are installed on both sides of the archway 6 15. When the lifting cylinder 1 pushes the sliding seat 18 to move up and down, due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com