Method for correcting bending deformation of thin and long thin walled pipe under gravity force

A thin-walled tube and slender technology, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve problems such as bending deformation and bending deformation of slender tubes, and achieve low cost, simple structure, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

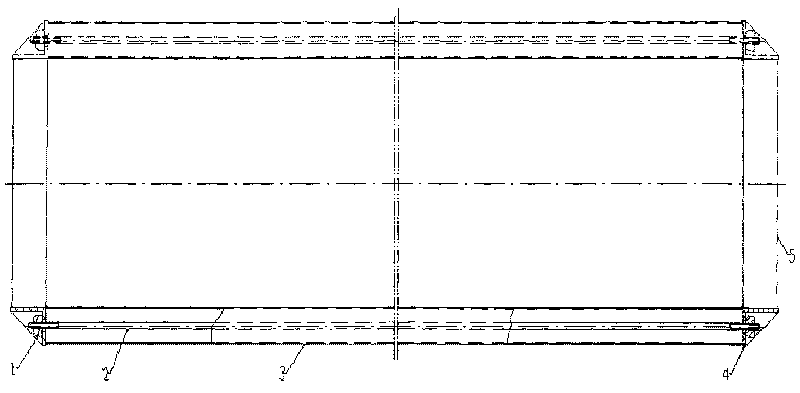

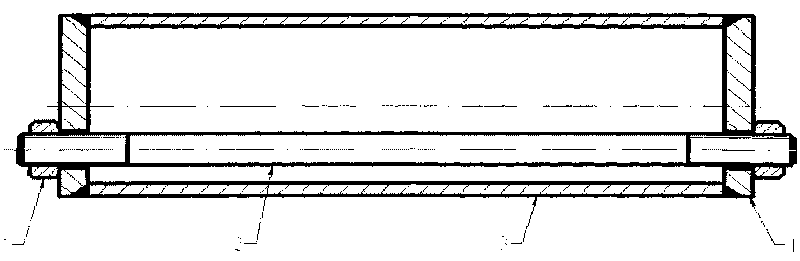

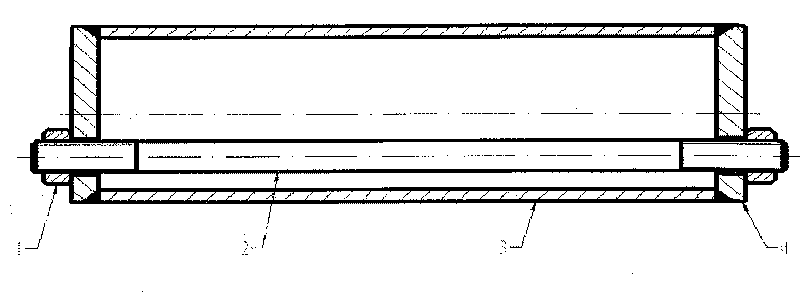

[0009] refer to figure 1 , figure 2 . figure 1 An embodiment of a rectangular bracket composed of two longitudinally elongated rectangular thin-walled tubes and two end beams is described. figure 2 Embodiments are described in which a single slender thin-walled tube corrects for buckling deformation. At least one rigid round steel 2 with threads at both ends runs through the bottom of the rectangular section wall of the elongated thin-walled tube 3; the round steel 2 is close to the bottom surface of the inner cavity of the rectangular thin-walled tube. Each of the sealing flanges 4 fixedly connected to the two ends of the slender thin-walled pipe 3 has a fastening hole through which the round steel 2 can pass through. The flange fastening hole is corrected by tightening the nuts 1 at both ends.

[0010] Because the deflection of the slender and thin-walled rectangular tube beam is related to the load condition, support condition, span length, sectional moment of inertia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com