Rack bar reinforced structure of conveyer belt riveting machine

A technology of reinforcing structure and buttoning machine, applied in the direction of belt fasteners, belts/chains/gears, mechanical equipment, etc., can solve the problems of easy deformation and bending, low rack strength, etc., to increase strength and solve deformation and bending , the effect of improving work quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

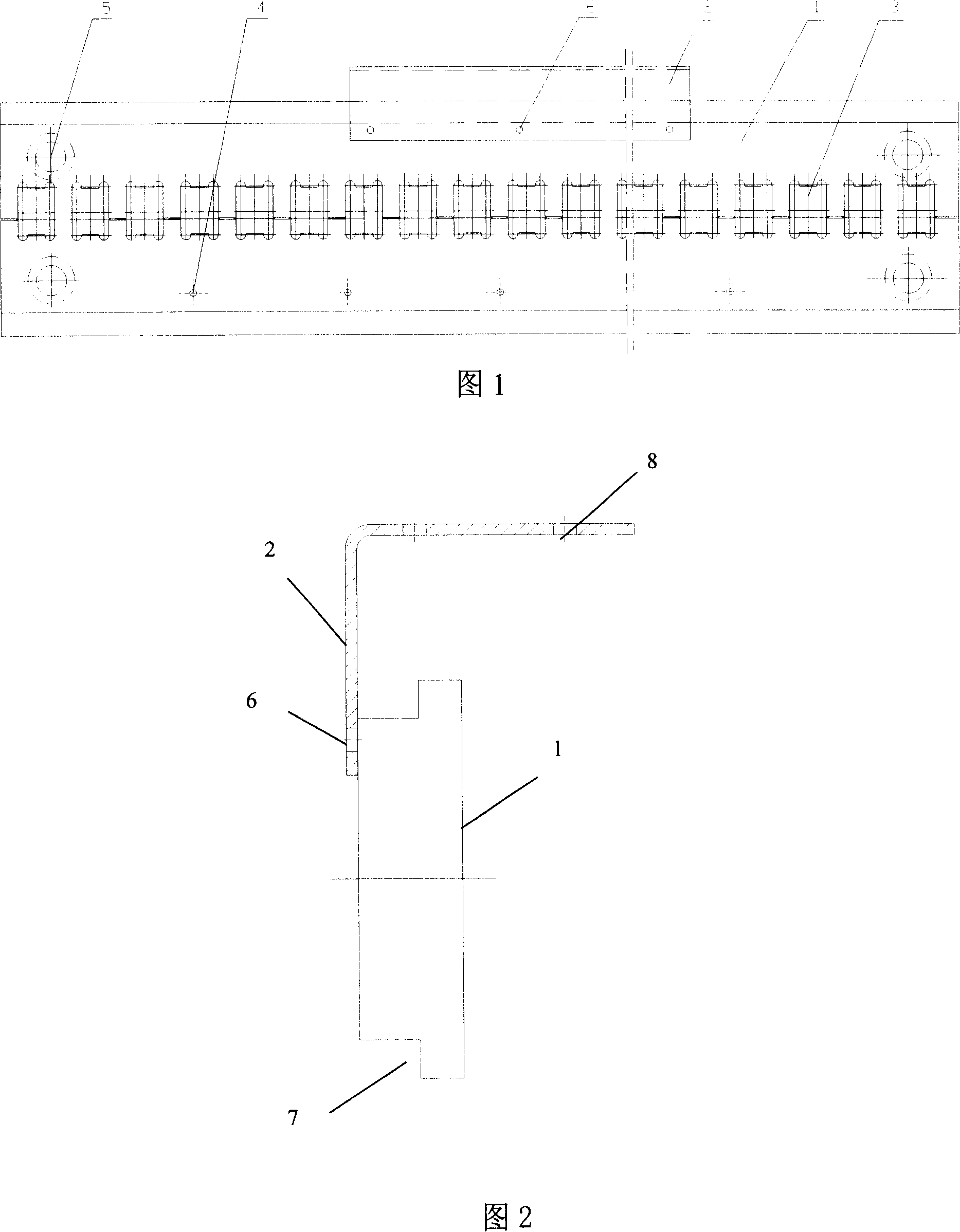

[0012] As shown in Figure 1, the rack reinforcement structure of a conveyor belt binding machine according to the present invention is composed of a rack plate 1 and a steel plate 2 with an L-shaped cross-section, wherein the rack plate 1 is above the other A plurality of holes 4 are arranged at a distance, and a plurality of holes 6 are arranged equidistantly on one side of the steel plate 2. The rack plate 1 and the steel plate 2 are connected by rivets or screws, and a plurality of holes 6 are arranged equidistantly on the other side of the steel plate 2. The holes 6 and the upper and lower sides of the rack plate 1 are provided with steps 7 .

[0013] Further, two counterbores 5 are respectively provided at both ends of the rack plate 1 .

[0014] Further, the rack plate 1 is provided with a plurality of special-shaped holes 3 .

[0015] Further, the holes are all threaded holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com