Circuit board with high-density circuits and method for manufacturing the circuit board

A manufacturing method and high-density technology, applied in the directions of printed circuit components, electrical connection printed components, and electrical connection formation of printed components, can solve the problems of electrical failure of conductive holes, gaps cannot be filled, etc., and achieve stable electrical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the technical solution provides the circuit board with the high-density circuit and its manufacturing method with specific examples.

[0022] The manufacturing method of the circuit board of the high-density circuit provided by the embodiment of the technical solution comprises the following steps:

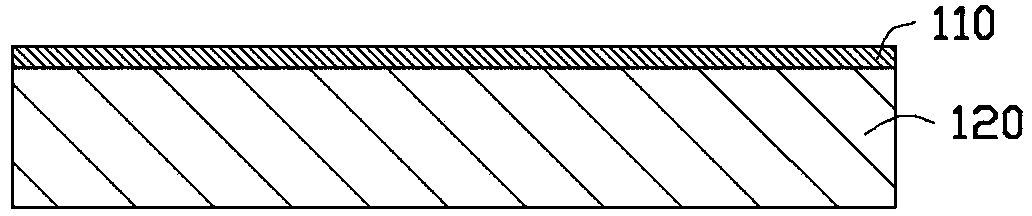

[0023] For a first step, see figure 1 , providing a first copper foil 110 .

[0024] The first copper foil 110 is a copper foil with a thickness of 5 microns to 15 microns.

[0025] In this embodiment, the first copper foil 110 is supported in order to facilitate the subsequent manufacturing process. A support plate 120 can also be detachably attached to one side surface of the first copper foil 110 . The support plate 120 can be made of metal or non-metal. The thickness of the support plate 120 is not limited, it only needs to have a flat surface and be able to support the first copper foil 110 .

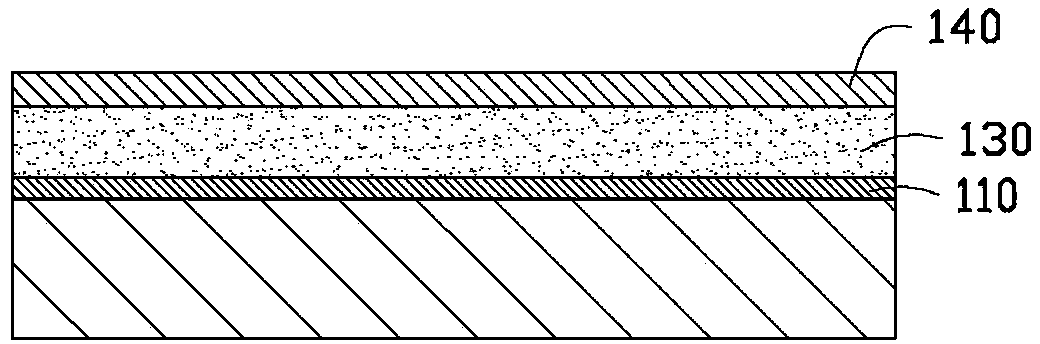

[0026] In the second step, see figure 2 , pressing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com