Corrugated pipe condensation heat exchanger and manufacture method thereof

A technology of condensing heat exchanger and manufacturing method, which is applied in the direction of air heater, fluid heater, energy-saving heating/cooling, etc. It can solve the problems of large smoke exhaust resistance, difficult to fix the shape, and insufficient heat exchange of pipelines, etc., to achieve Improved heat transfer efficiency, simple manufacturing process, and consistent tube spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the essence of the present invention, the specific implementation of a bellows condensing heat exchanger provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0034] Examples of condensing heat exchangers

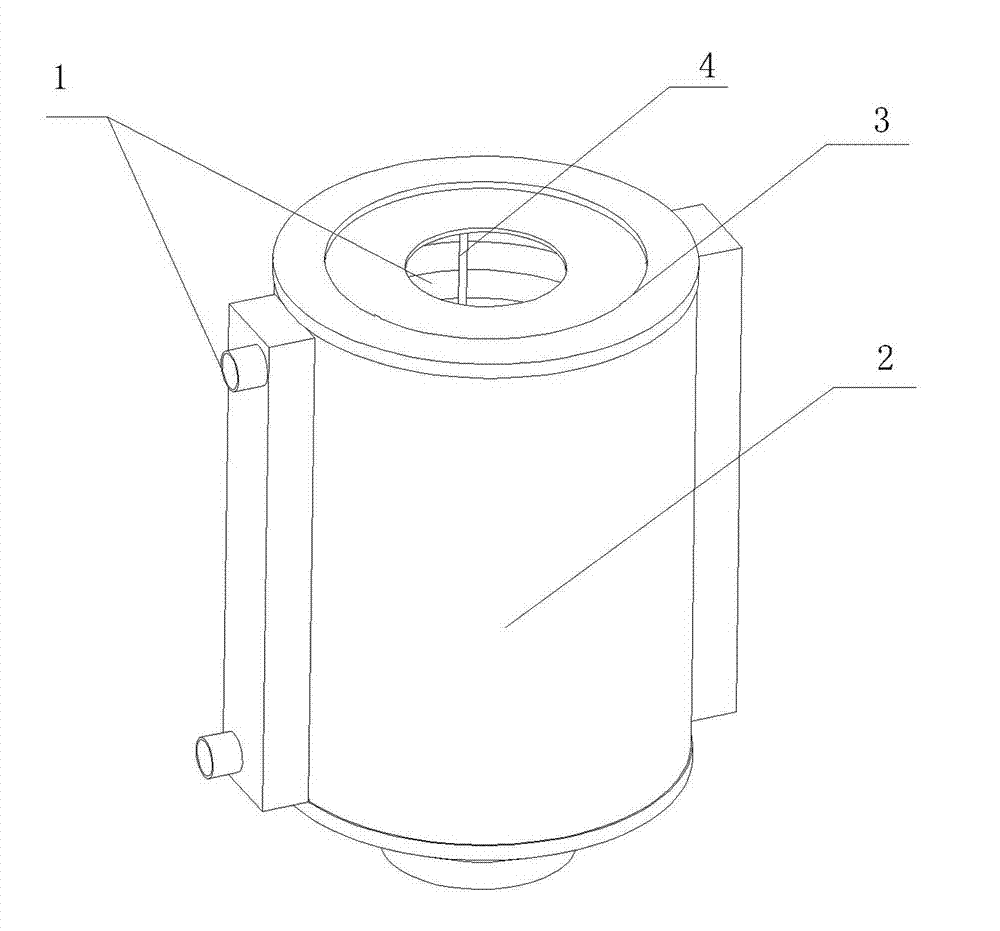

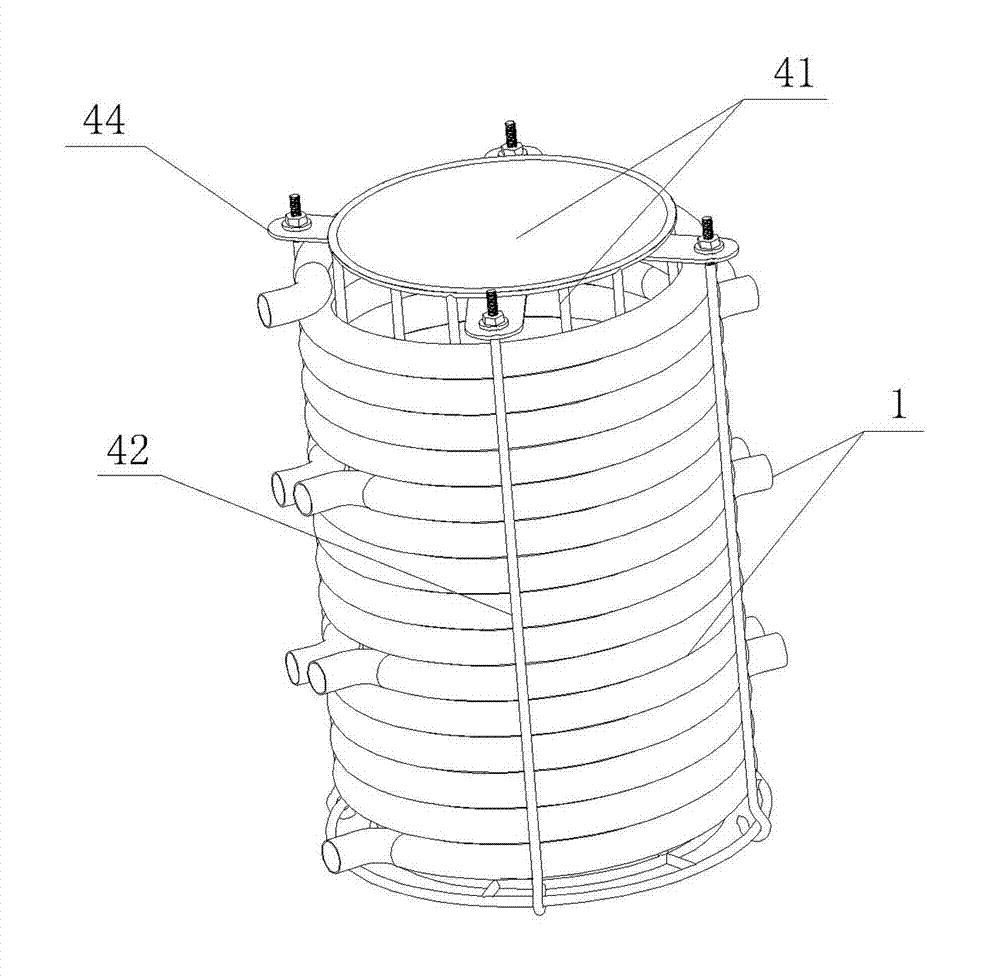

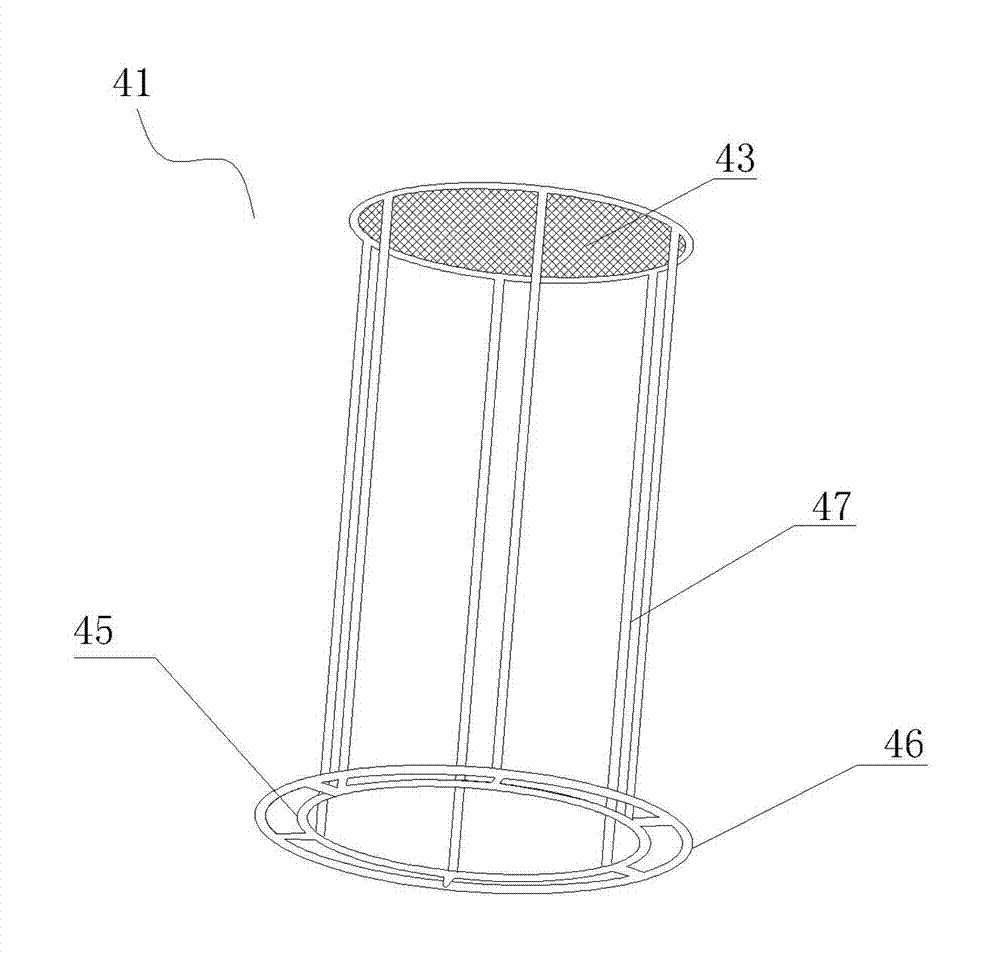

[0035] Such as figure 1 , figure 2 As shown, a bellows condensing heat exchanger includes: a bellows 1, a condensing heat exchanger shell 2 and an upper and lower end cover 3, and it is characterized in that a frame 4 is arranged inside the condensing heat exchanger shell 2, At least one group of bellows 1 is coiled and fixed on the frame 4 to form a helical structure, the pitch of the helical structure is equal, and the helical axes are the same straight line. Preferably, the bellows 1 is made of stainless steel and consists of six groups coiled continuously on the frame; the frame 4 includes: a frame body 41, a fixed rod 42 and a pressing piece 44 movably mounted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com