Glass guide rail structure for automobile rear door

A glass guide rail and rear door technology, which is applied to vehicle parts, engine seals, sealing devices, etc., can solve problems such as loose fixation, and achieve the effect of meeting the shape design intention, beautiful shape, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

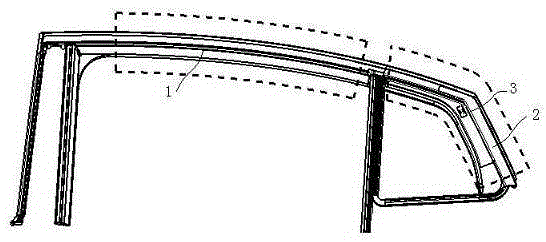

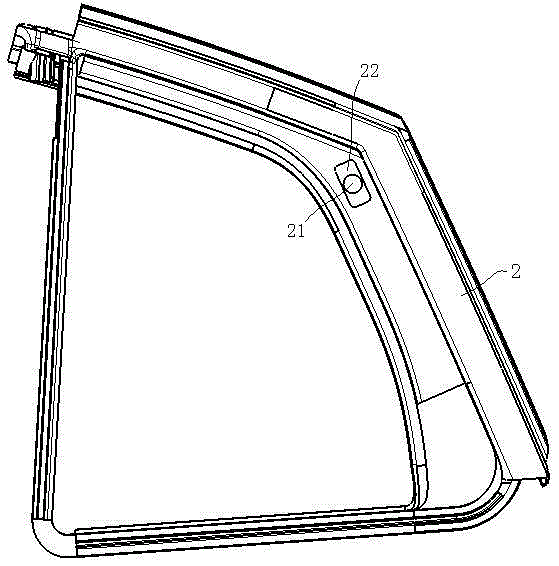

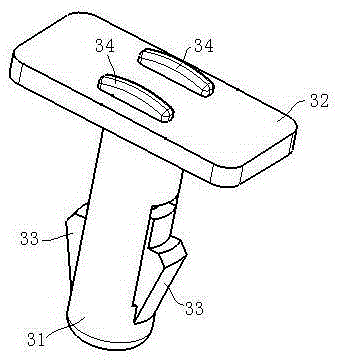

[0029] Figure 1 to Figure 5 Shown is a glass guide rail structure for the rear door of an automobile, which includes a constant-section part 1 , a variable-section part 2 and buckles 3 . The constant cross-section part 1 and the variable cross-section part 2 are combined through an injection molding process, and then fixed to the door sheet metal through a buckle 3 . The constant cross-section part 1 of the glass run channel is compounded with rubber and aluminum skeleton, and the specified cross-section and certain length are obtained by extrusion molding and cutting to length. Then, the constant cross-section part 1 is placed in an injection mold, and through injection molding, a semi-finished product having both a variable cross-section and a constant cross-section is made. The buckle 3 is directly locked on the hole reserved by injection molding of the variable sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com