Automatic butt joint machine for flue pipe production

An automatic docking and flue pipe technology, which is applied in applications, household utensils, tubular objects, etc., can solve the problems of poor contact and gaps in the docking interface, and achieve good docking, simple operation, and convenient grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

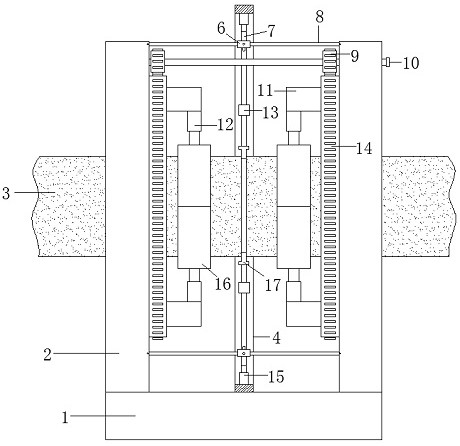

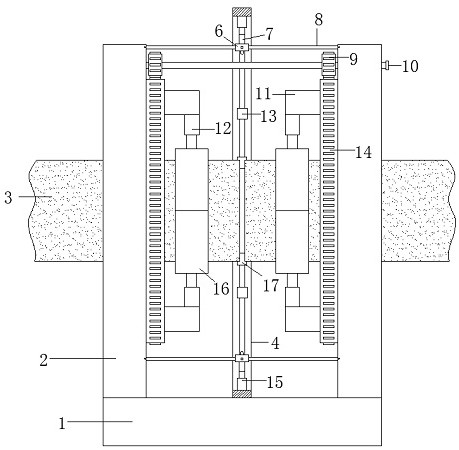

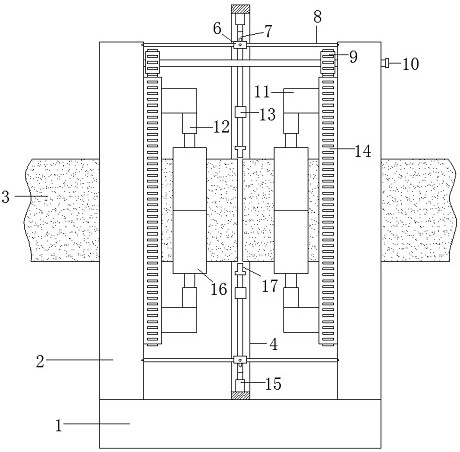

[0027] refer to Figure 1-3 : An automatic butt joint machine for flue pipe production, comprising a base plate 1, characterized in that the top of the base plate 1 is slidably connected with two support plates 2 along the length direction, and the sides of the two support plates 2 that are close to each other are rotatably connected with a transmission The upper part of the transmission device is equipped with a power device, and the sides of the two transmission devices close to each other are fixed with a clamping device. The top of the base plate 1 is fixedly connected with an arc-shaped fixing plate 4, and the upper and lower sides of the arc-shaped fixing plate 4 Both are provided with a lifting device, and the sides of the two lifting devices that are close to each other are provided with a grinding device, and the inside of the arc-shaped fixed plate 4 is provided with a welding device.

[0028] In the present invention, the power device includes a power shaft 10 that ...

Embodiment 2

[0032] refer to Figure 2-6 : An automatic butt joint machine for flue pipe production, in the present embodiment, including the lifting device including the lifting push rod motor 15 fixedly connected to the upper and lower sides of the arc fixed plate 4, two lifting push rod motors 15 close to one side The output shafts are all fixedly connected with connecting plates 7, wherein the output shaft of the lifting motor 15 shrinks and stretches out, which can move the two connecting plates 7 away from and close to each other.

[0033] In the present invention, the grinding device includes two arc-shaped T plates 17, and the sides of the two arc-shaped T plates that are far away from each other are fixedly connected with the sides of the two connecting plates 7 that are close to each other, and the inner arc of the arc-shaped fixing plate 4 is fixedly connected symmetrically. There are two reinforcing plates 13, and the connecting plates 7 are movable through the reinforcing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com