Process for producing papermaking pulp by taking corn straws as raw materials

A technology of corn stalks and technology, applied in the field of technology, can solve the problems of insufficient plant fiber raw material resources, unreasonable application of fiber characteristic structure, dependence on imports of pulp for papermaking, etc., to solve the problem of resource utilization, realize resource utilization, The effect of considerable economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

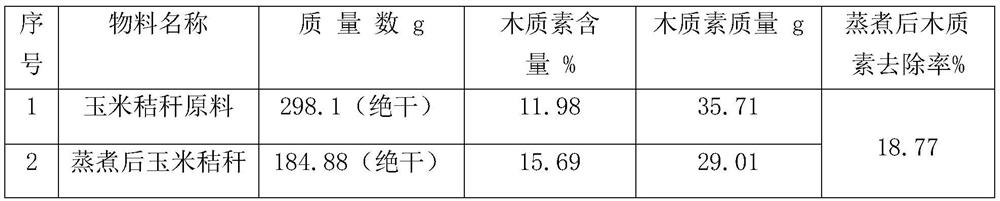

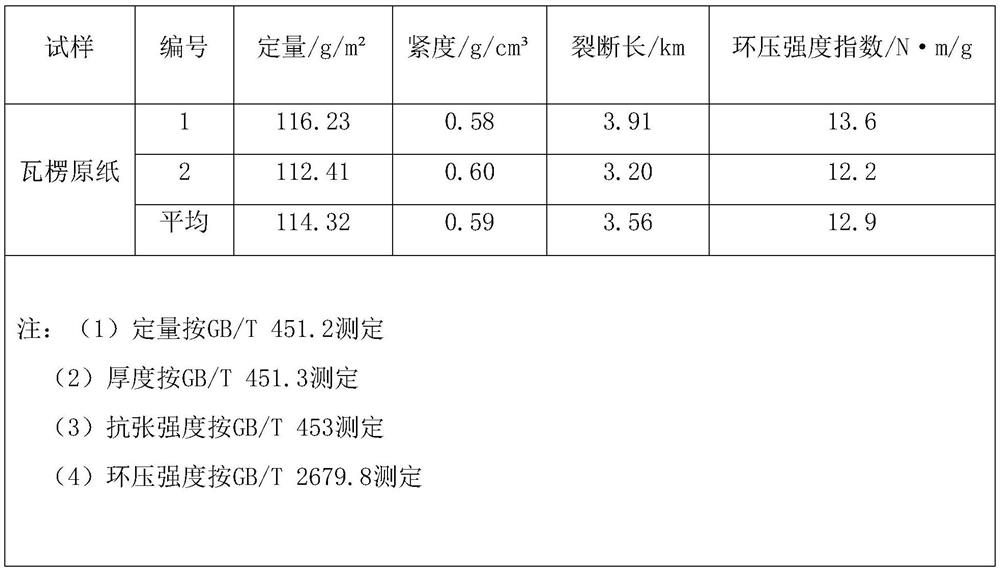

Embodiment 1

[0030] This embodiment discloses a process for producing pulp for papermaking using corn stalks as a raw material, comprising the following steps:

[0031] Ⅰ. Send the processed corn stalks into the low-temperature cooker through the auger, add water according to the solid-to-liquid ratio of 1:15, and cook at 60°C for 180 minutes to complete the low-temperature cooking; The length of corn stalk silk is 10-80mm, the width is 0.5-8mm, no dust, and the qualified rate is more than 70%;

[0032] Ⅱ. Wash the material after low-temperature cooking, so that the content of dissolved substances in the material is lower than 0.2%;

[0033] Ⅲ. Send the washed material directly into the screw extrusion separator to separate part of the water in the material, and finally, control the solid-liquid ratio of the material at about 1:3;

[0034] Ⅳ. The material obtained by Ⅲ is sent into the high-pressure cooker through the feeder, and the temperature of the material in the high-pressure cooker...

Embodiment 2

[0049] This embodiment discloses a process for producing pulp for papermaking using corn stalks as a raw material, comprising the following steps:

[0050] Ⅰ. Send the processed corn stalks into the low-temperature cooker through the auger, add water according to the solid-to-liquid ratio of 1: 12, and cook at 80°C for 120 minutes to complete the low-temperature cooking; The length of corn stalk silk is 10-80mm, the width is 0.5-8mm, no dust, and the qualified rate is more than 70%;

[0051] Ⅱ. Wash the material after low-temperature cooking, so that the content of dissolved substances in the material is lower than 0.2%;

[0052] Ⅲ. Send the washed material directly into the screw extrusion separator to separate part of the water in the material, and finally, control the solid-liquid ratio of the material at about 1:3;

[0053] Ⅳ. The material obtained by Ⅲ is sent into the high-pressure cooker through the feeder, and the temperature of the material in the high-pressure cooker ...

Embodiment 3

[0069] This embodiment discloses a process for producing pulp for papermaking using corn stalks as a raw material, comprising the following steps:

[0070] Ⅰ. Send the processed corn stalks into the low-temperature cooker through the auger, add water according to the solid-to-liquid ratio of 1:20, and cook at a temperature of 70°C for 170 minutes to complete the low-temperature cooking; The length of corn stalk silk is 10-80mm, the width is 0.5-8mm, no dust, and the qualified rate is more than 70%;

[0071] Ⅱ. Wash the material after low-temperature cooking, so that the content of dissolved substances in the material is lower than 0.2%;

[0072] Ⅲ. Send the washed material directly into the screw extrusion separator to separate part of the water in the material, and finally, control the solid-liquid ratio of the material at about 1:3;

[0073] Ⅳ. The material obtained by Ⅲ is sent into the high-pressure cooker through the feeder, and the temperature of the material in the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com