Organic fertilizer with high humic acid content and preparation method thereof

A humic acid and organic fertilizer technology, applied in the preparation of organic fertilizers, organic fertilizers, bio-organic part treatment, etc., can solve the problems of random discharge of filter mud, environmental pollution, etc., and achieve environmental protection and high conversion rate of humic acid , the effect of high humic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of organic fertilizer with high content of humic acid prepared by utilizing sulfite process sugar factory filter mud, comprising the following steps:

[0027] Step A: screening of fermentation strains, select Bacillus subtilis (Bacillus subtilis, number ACCC11060), Bacillus megaterium (Bacillus megaterium, number ACCC10010) and jelly-like Bacillus (also known as silicate bacteria) (Bacillus mucilaeinosus, number ACCC11103) mixed as Fermentation strains, these three strains are purchased from the National Culture Collection Center, and the mass ratio of the three is 1:1:1, that is, each accounts for one-third.

[0028] Step B: Use the screened fermentation strains for the production of koji, operate under sterile conditions, inoculate and cultivate the purified strains, and the obtained strains are first-class seeds; shaker amplification, the obtained first-class seeds Inoculate into a triangular flask, cultivate and amplify the number of bacteria, and cultivate f...

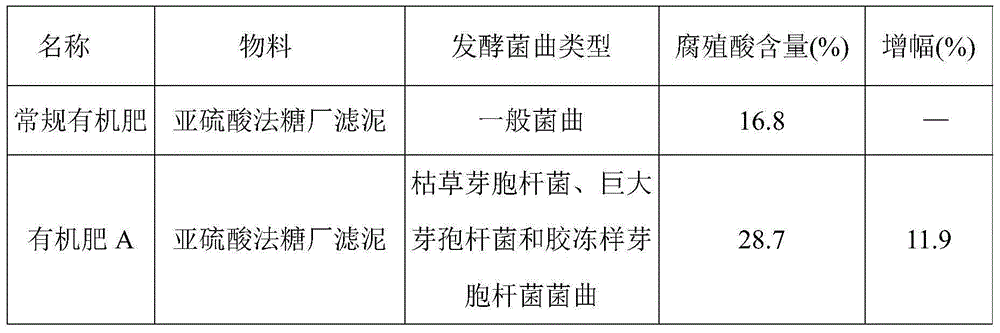

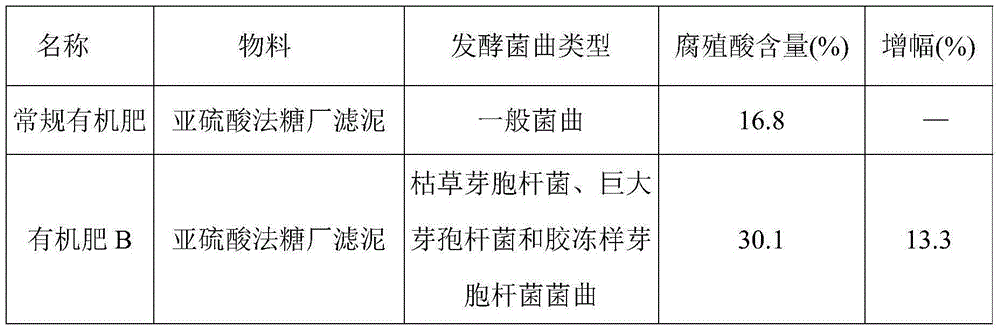

Embodiment 2

[0035] On the basis of embodiment 1, the bacterium koji of this example is made up of Bacillus subtilis, gigantic bacillus and jelly-like bacillus, and the amount of bacterium koji is 3.0 kilograms of bacterium koji per ton of sulfite sugar factory filter mud, to obtain organic Fat B.

[0036] Contrast test adopts the general bacterium koji on the market, and general bacterium koji dosage is 5.0 kilograms of bacterium koji per ton of sulfitation sugar factory filter mud, obtains conventional organic fertilizer; ACCC11068) composition.

[0037] The organic fertilizer B was compared with the conventional organic fertilizer, and the results are shown in Table 2. From the comparison of the data in Table 2, it can be seen that the humic acid content of organic fertilizer B is 30.1%, and the conventional organic fertilizer is only 16.8%. Organic fertilizer B is 13.3% higher than conventional organic fertilizer, and has a higher humic acid conversion rate .

[0038] Table 2 Compar...

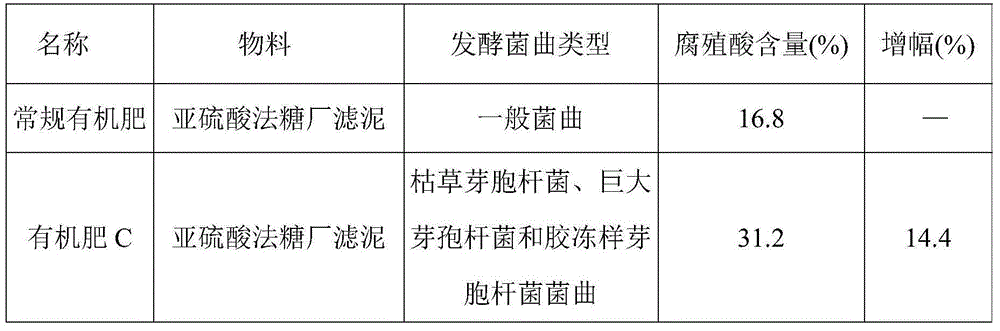

Embodiment 3

[0041] On the basis of Example 1, the amount of bacterium koji used in this example is 4.5 kilograms of bacterium koji used for per ton of sulfitic sugar factory filter mud to obtain organic fertilizer C.

[0042] Contrast test adopts the general bacterium koji on the market, and general bacterium koji dosage is 5.0 kilograms of bacterium koji per ton of sulfitation sugar factory filter mud, obtains conventional organic fertilizer; ACCC11068) composition.

[0043]The organic fertilizer C was compared with the conventional organic fertilizer, and the results are shown in Table 3. From the comparison of the data in Table 3, it can be seen that the humic acid content of organic fertilizer C is 31.2%, and that of conventional organic fertilizer is only 16.8%. Organic fertilizer C is 14.4% higher than conventional organic fertilizer, and has a higher humic acid conversion rate .

[0044] Table 3 Comparison table of humic acid content between organic fertilizer C and conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com