Macromolecular composite anatonosis storage-increment material and preparation method thereof

A technology of macromolecule and infiltration, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problem that superabsorbent resin is not suitable for farmland use, and achieve the effect of reducing water evaporation and improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

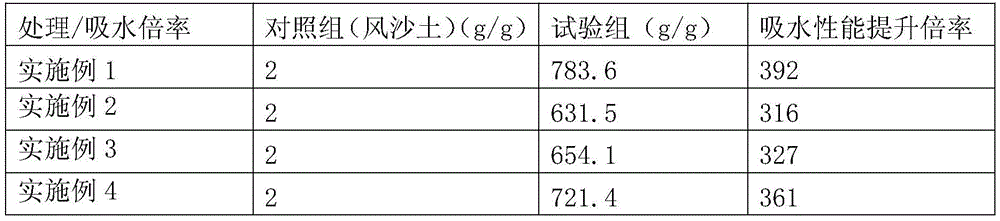

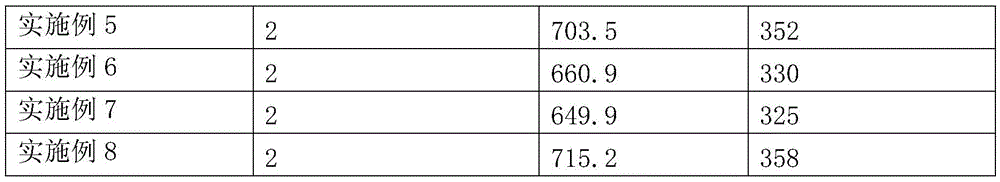

[0018] Humic acid 2%, acrylic acid 83%, carboxymethyl cellulose 14%, initiator potassium persulfate 0.02%, crosslinking agent N,N-methylenebisacrylamide 0.01% and stabilizer phosphite 0.01%. After adding and mixing the above materials in order, pass in an external inert gas for 30 minutes, stir at a speed of 500 rpm for 30 minutes, fully react for 4 hours, take it out, wash and dry, and granulate to obtain the finished product. The water absorption rate of this material is 783.6g / g, which is 392 times higher than the water absorption capacity of aeolian sandy soil.

[0019] The seepage-increasing and storage-expanding material in this embodiment can be used as a drought-resistant, water-retaining and seepage-enhancing agent for sandy loam, and the effect of sowing after cultivating the soil is better.

Embodiment 2

[0021] Humic acid 2%, acrylic acid 82%, carboxymethyl cellulose 14%, initiator potassium persulfate 0.02%, crosslinking agent N,N-methylenebisacrylamide 0.01% and stabilizer phosphite 0.01%. Add and mix the above materials in order, pass in an external inert gas for 20 minutes, stir at 500 rpm for 20 minutes, fully react for 4 hours, take it out, wash and dry, and granulate to obtain the finished product. The water absorption rate of this material is 631.5g / g, which is 316 times higher than the water absorption capacity of aeolian sandy soil.

[0022] The implementation usage of this material is the same as Example 1.

Embodiment 3

[0024] Humic acid 3%, acrylic acid 82%, carboxymethyl cellulose 14%, initiator potassium persulfate 0.02%, crosslinking agent N,N-methylenebisacrylamide 0.01% and stabilizer phosphite 0.01%. Add and mix the above materials in order, pass in an external inert gas for 15 minutes, stir at 500 rpm for 30 minutes, fully react for 3 hours, take it out, wash and dry, and granulate to obtain the finished product. The water absorption rate of this material is 654.1g / g, which is 327 times higher than the water absorption capacity of aeolian sandy soil.

[0025] The implementation usage of this material is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com