Iron-manganese oxide based heavy metal curing agent and preparation method and applications thereof

A technology of iron-manganese oxides and heavy metals, applied in chemical instruments and methods, applications, fertilizer mixtures, etc., can solve the problem of the inability to fix multiple heavy metal ions at the same time, the lack of research on the long-term stability of solidified bodies, and the lack of large-scale engineering practice Application and other issues, to achieve the effect of beneficial soil virtuous cycle, strong solidification and stabilization ability of heavy metals, and improvement of soil continuous cropping obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

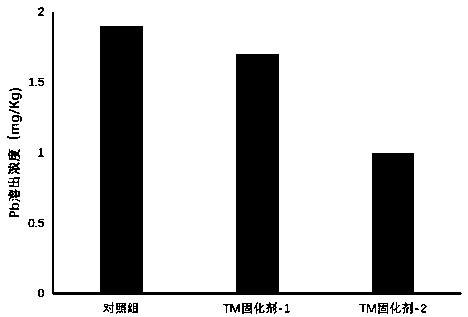

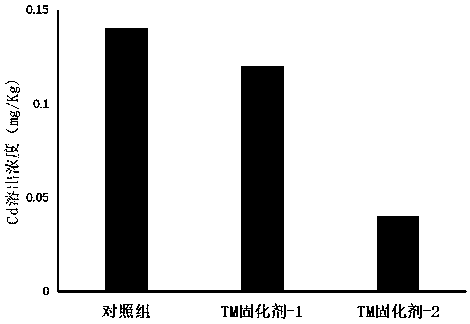

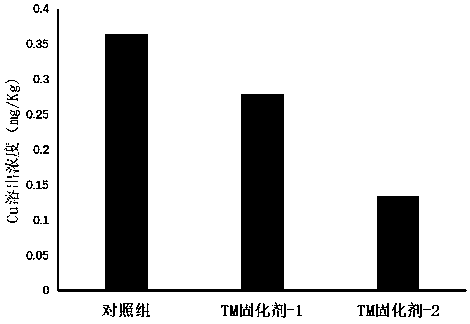

Examples

Embodiment 1

[0038] The present embodiment provides a kind of heavy metal curing agent based on iron-manganese oxide, comprising the following components by mass percentage: ferromanganese tailings slag 15%, pH regulator 8%, humus 37%, chitosan 22% , straw ash 18%.

[0039] Of which: in ferromanganese tailings slag, SiO 2 The content is 25-30%, CaSO 4 The content is 15-20%, Fe(OH) 3 The content is 6-10%, MnO 2The content of calcium salt is 5%-10%; in the pH regulator, the content of calcium salt is 30%-40%, Mg(OH) 2 The content is 10%-15%, and the calcium salt includes at least one of calcium carbonate and calcium sulfate; in humus, the C content is 55%-60%, the N content is 4%-7%, and humic acid and humin The content is not less than 4%.

[0040] The preparation method of the above-mentioned heavy metal curing agent is as follows: respectively pulverize ferromanganese tailings, pH regulator, humus, chitosan, and straw ash, pass through a 150-mesh sieve, and then mix evenly according ...

Embodiment 2

[0043] The present embodiment provides a kind of heavy metal curing agent based on iron-manganese oxide, comprising the following components by mass percentage: 10% of ferromanganese tailings slag, 10% of pH regulator, 40% of humus, 25% of chitosan , Straw ash 15%.

[0044] Of which: in ferromanganese tailings slag, SiO 2 The content is 25-30%, CaSO 4 The content is 15-20%, Fe(OH) 3 The content is 6-10%, MnO 2 The content of calcium salt is 5%-10%; in the pH regulator, the content of calcium salt is 30%-40%, Mg(OH) 2 The content is 10%-15%, and the calcium salt includes at least one of calcium carbonate and calcium sulfate; in humus, the C content is 55%-60%, the N content is 4%-7%, and humic acid and humin The content is not less than 4%.

[0045] The preparation method of the above-mentioned heavy metal curing agent is as follows: respectively pulverize ferromanganese tailings, pH regulator, humus, chitosan, and straw ash, pass through a 100-mesh sieve, and then mix eve...

Embodiment 3

[0048] The present embodiment provides a kind of heavy metal curing agent based on iron-manganese oxide, comprising the following components by mass percentage: 20% of ferromanganese tailings slag, 10% of pH regulator, 35% of humus, 15% of chitosan , Straw ash 20%.

[0049] Of which: in ferromanganese tailings slag, SiO 2 The content is 25-30%, CaSO 4 The content is 15-20%, Fe(OH) 3 The content is 6-10%, MnO 2 The content of calcium salt is 5%-10%; in the pH regulator, the content of calcium salt is 30%-40%, Mg(OH) 2 The content is 10%-15%, and the calcium salt includes at least one of calcium carbonate and calcium sulfate; in humus, the C content is 55%-60%, the N content is 4%-7%, and humic acid and humin The content is not less than 4%.

[0050] The preparation method of the above-mentioned heavy metal curing agent is as follows: respectively pulverize ferromanganese tailings, pH regulator, humus, chitosan, and straw ash, pass through a 120-mesh sieve, and then mix uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com