Steel and titanium alloy low-temperature pulse ion nitrocarburizing and cathode arc ion plating M/MN alternate plating thick-film technology

A cathodic arc and thick film process technology, which is applied in ion implantation plating, metal material coating process, sputtering plating, etc., can solve the problems of environmental pollution, low hardness and wear resistance of titanium alloy, and achieve environmental protection Pollution, reduction of workpiece deformation, and elimination of stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

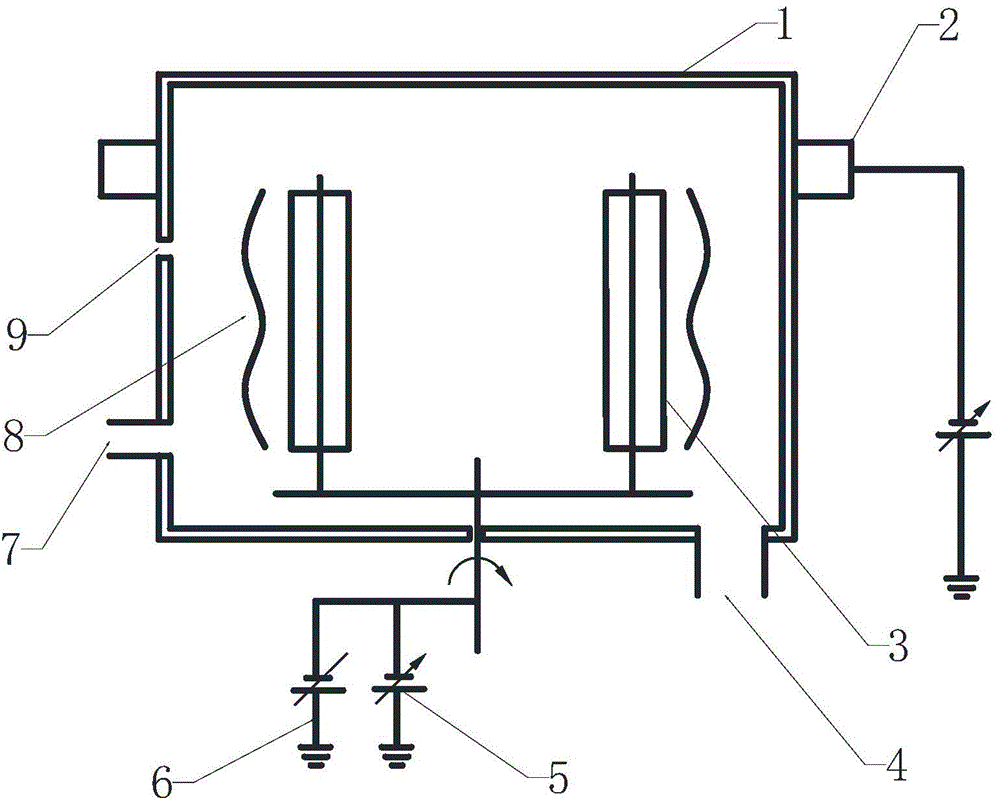

[0039]The low-temperature pulse ion nitrocarburizing and cathodic arc ion plating Cr / CrN alternate thick film plating process of piston ring replaces the current electroplating hard chrome process, and adopts low temperature pulse ion nitrocarburizing and cathodic arc ion plating technology as shown in the attached drawing

[0040] Workpiece name: Piston ring

[0041] Workpiece material: 304 stainless steel

[0042] Pre-plating treatment: cold rolling

[0043] Performance requirements: nitrocarburizing layer + Cr / CrN alternate composite thick film layer, hardness 1400 ~ 1600Hv

[0044] Step 1: After the workpiece 3 is polished and ultrasonically cleaned and dried, it is loaded into the vacuum chamber 1 .

[0045] Step 2: Vacuum

[0046] The vacuum chamber 1 is vacuumed 4, and the vacuum degree reaches 2X10 -4 Pa.

[0047] Step 3: Workpiece 3 heating

[0048] The workpiece 3 is subjected to stress relief annealing after being cold-rolled or cold-drawn and the shape of the...

Embodiment 2

[0069] Cam pumping low-temperature pulse ion nitrocarburizing and cathodic arc ion plating Cr / CrN alternate thick film plating process replaces the current electroplating hard chromium process, adopts low-temperature pulse ion nitrocarburizing and cathodic arc ion plating technology as shown in the attached figure,

[0070] Workpiece name: cam pump

[0071] Workpiece material: 20CrMnTi

[0072] Heat treatment before plating: normalizing

[0073] Performance requirements: nitrocarburizing layer + Cr / CrN alternate composite thick film layer, hardness 1600 ~ 1800Hv

[0074] Step 1: After the workpiece 3 is polished and ultrasonically cleaned and dried, it is loaded into the vacuum chamber 1 .

[0075] Step 2: Vacuum

[0076] The vacuum chamber 1 is vacuumed 4, and the vacuum degree reaches 2X10 -4 Pa.

[0077] Step 3: Workpiece 3 heating

[0078] Start heating device 8, workpiece 3 temperature 450 ℃.

[0079] Step 4: Preparation of modified layer by low temperature pulse i...

Embodiment 3

[0099] Low-temperature pulse ion nitrocarburizing and cathodic arc ion plating Ti / TiN alternate thick film plating process for aerospace devices replaces the current electroplating hard chrome process.

[0100] Workpiece material: TC-4 (Ti-6Al-4V)

[0101] Pre-plating treatment: normalizing

[0102] Performance requirements: nitrocarburizing layer + Ti / TiN alternate composite thick film layer, hardness 1800-2000Hv

[0103] Step 1: After the workpiece 3 is polished and ultrasonically cleaned and dried, it is loaded into the vacuum chamber 1 .

[0104] Step 2: Vacuum

[0105] The vacuum chamber 1 is vacuumed 4, and the vacuum degree reaches 2X10 -4 Pa.

[0106] Step 3: Workpiece 3 heating

[0107] Start the heating device 8, and the temperature of the workpiece 3 is 420°C.

[0108] Step 4: Preparation of modified layer by low temperature pulse ion nitrocarburizing

[0109] Adjust the vacuum degree of vacuum chamber 1 to 70Pa, feed ammonia gas 9, turn off argon gas 7, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com