Miniature gas enricher and preparation method thereof

A concentrator and gas technology, which is applied in the structural design and preparation of micro-gas concentrators, can solve the problems of high cost, mismatch of concentrators, and low enrichment factor of silicon microstructure concentrators, and achieve Low cost, low cost, rapid temperature rise and good desorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

[0044] The metal substrate of the micro-packed enricher of the present invention is copper T2 as an example, but it is not limited to T2, and can also be other metal or alloy materials with good performance; the enrichment object is ethylene gas as an example, and the adsorbent material is CarbosieveSII .

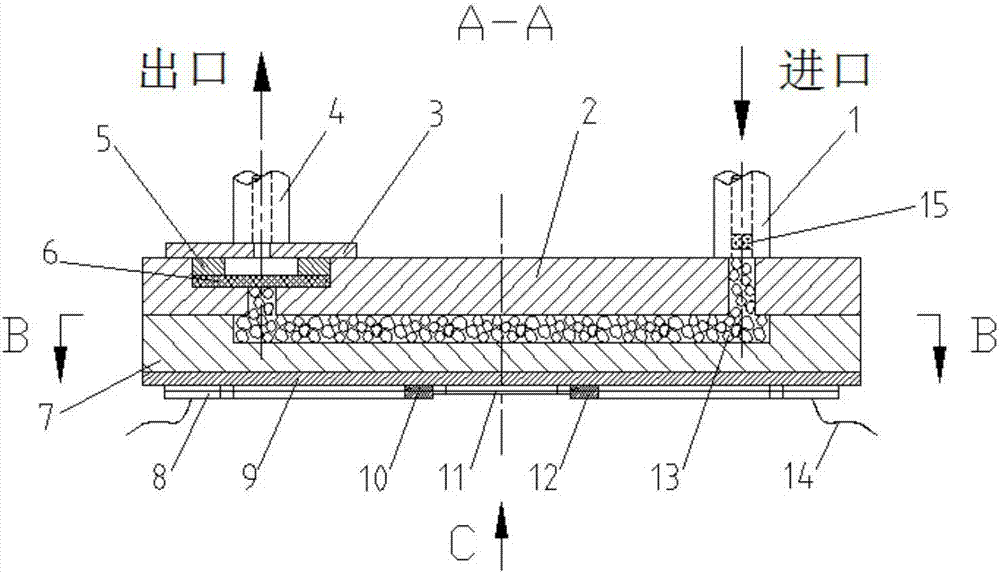

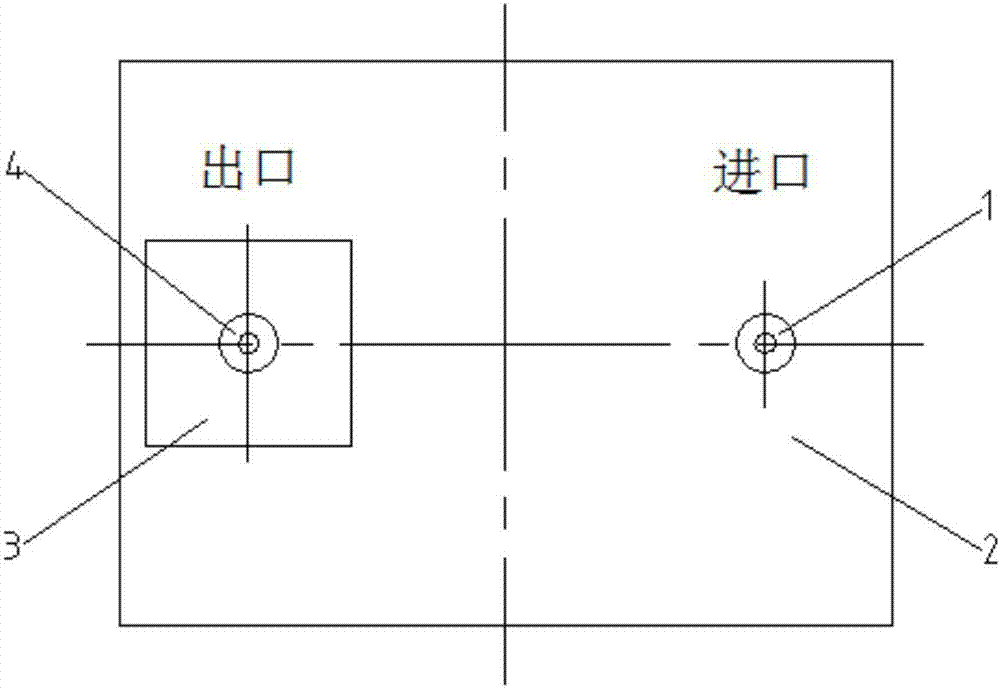

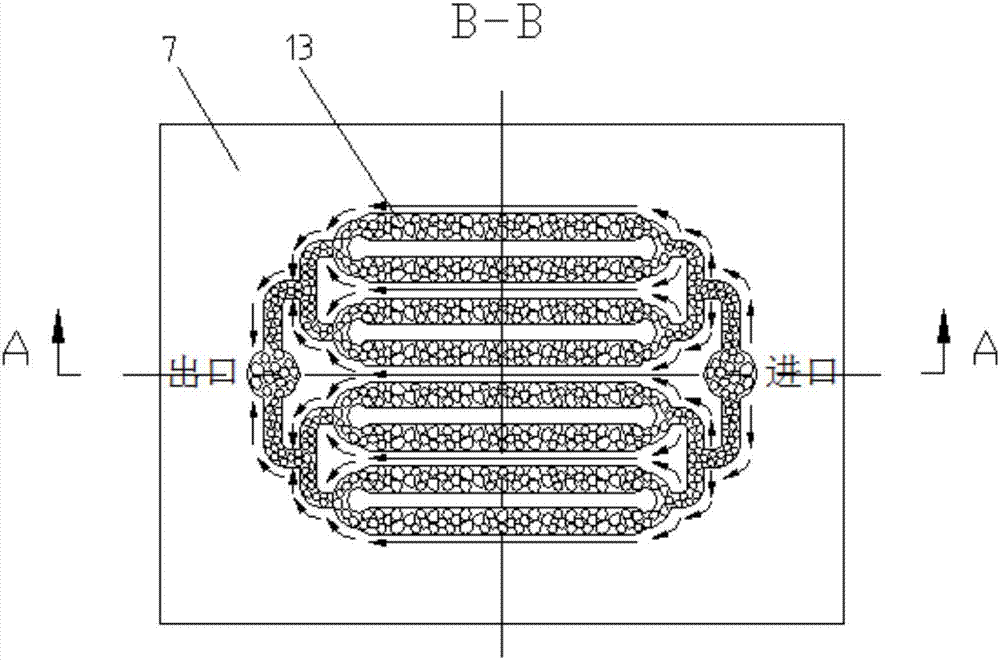

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a micro gas concentrator, including encapsulation layer 2, filling layer 7, stainless steel mesh 6, SiO 2 Dielectric layer 9 , Ti adhesive layer 10 , Ru heating resistance wire 12 , Pt sensitive resistance wire 11 , inlet transfer tube 1 and outlet transfer tube 4 . Wherein, the encapsulation layer 2 and the filling layer 7 are made of red copper T2, a metal material with better heat transfer performance than s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com