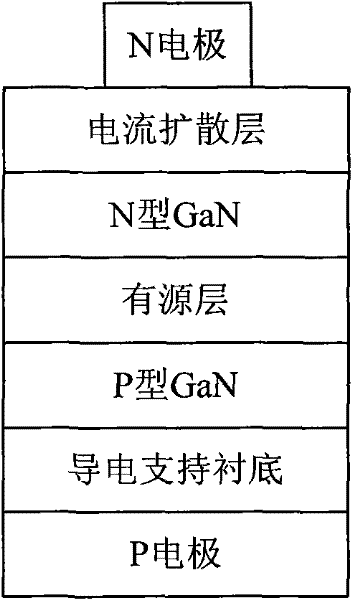

A kind of vertical structure light-emitting diode and its manufacturing method

A light-emitting diode and vertical structure technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complex process, improvement, and unfavorable yield rate, etc., and achieve the effect of increasing light output area, reducing film stress, and reducing debris phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

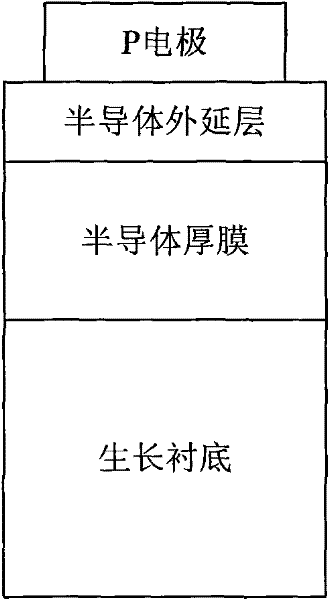

[0025] Please see Figure 2 to Figure 7 , specifically illustrate the implementation process of the vertical structure light-emitting diode manufacturing method of the present invention:

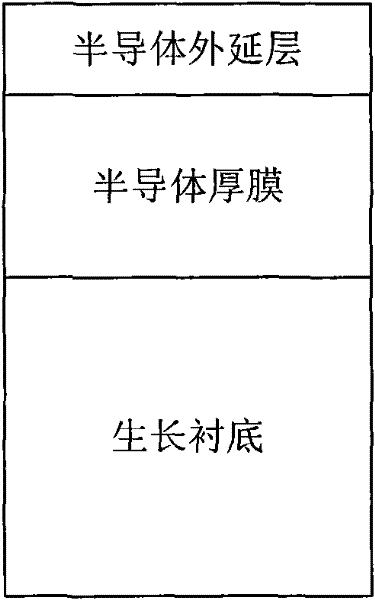

[0026] Step 1, growing a semiconductor thick film on the growth substrate, and then growing a semiconductor epitaxial layer on the semiconductor thick film, the semiconductor epitaxial layer at least includes an N-type semiconductor layer, an organic layer located on the N-type semiconductor layer source layer, and a P-type semiconductor layer located on the active layer, such as figure 2 shown.

[0027] Among them, chemical vapor deposition (CVD), plasma chemical vapor deposition (PECVD), metal compound vapor deposition (MOCVD), molecular beam epitaxy (MBE) and other methods can be used to grow semiconductor thick films and semiconductor epitaxial layers. The growth substrate is a Si substrate, a SiC substrate or a sapphire substrate, and a sapphire substrate is preferred in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com