Manufacturing technique for three-dimensional structure carrier of ceramic metal membrane

A 3-dimensional structure, ceramic metal technology, applied in the process of thick film product processing and production, in the field of ceramic metal thin film, can solve the problems of inability to meet the production and processing requirements of ceramic metal film, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

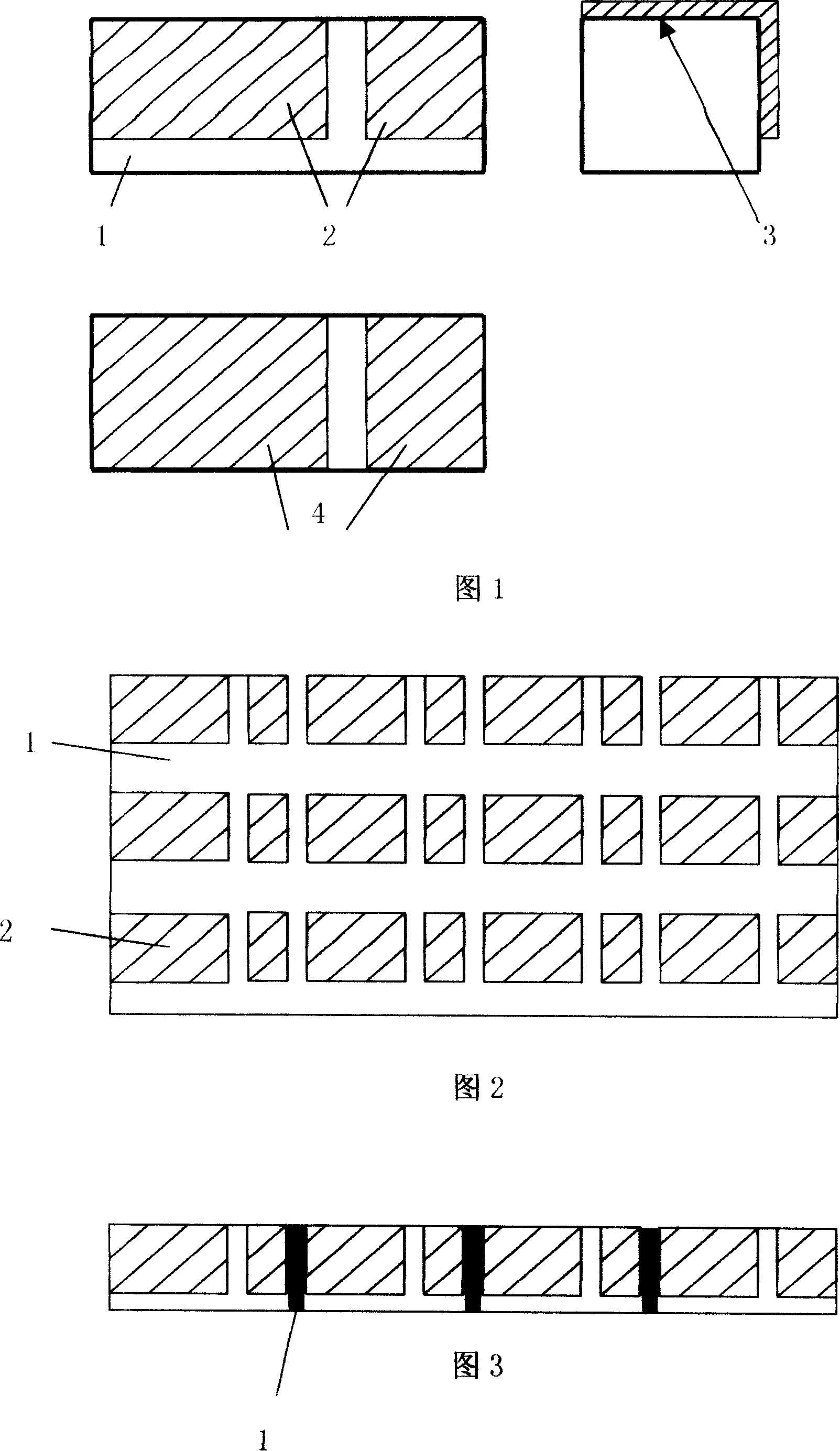

[0007] Figure 2, if it is a thin film process, the required plane pattern is lithographically etched with a designed lithography plate on a ceramic substrate with a thickness of less than or equal to 1 mm that has been metallized. 1 is a ceramic substrate, 2 is a metal film pattern. If it is a thick film process, the metal film pattern is directly printed on the ceramic substrate with a screen with a pattern and gold paste; The gold paste pattern is printed on the fixture; the gold paste is sintered and solidified in a high temperature furnace at about 800°C.

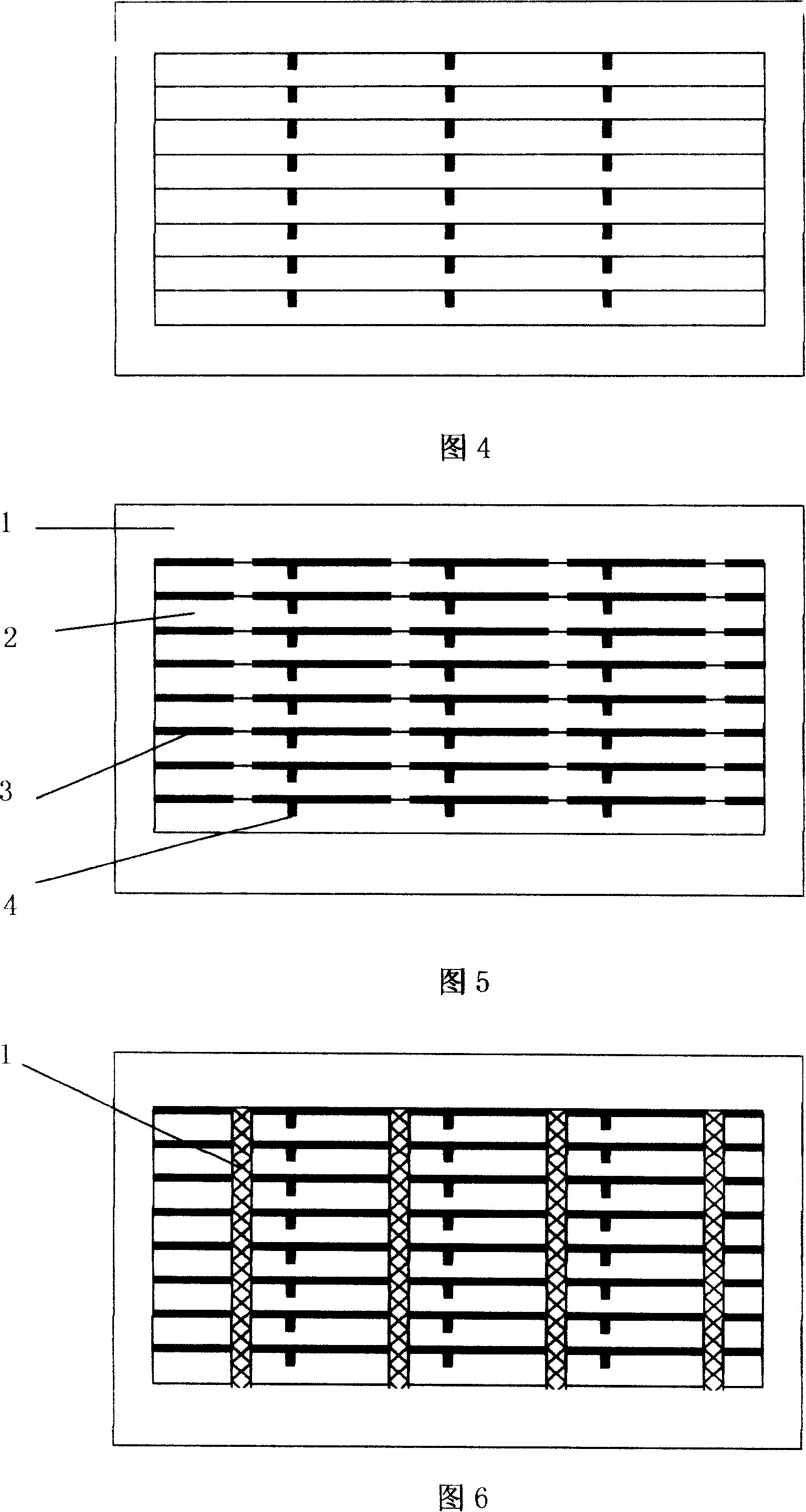

[0008] Figure 3, use a grinding wheel dicing machine to cut according to the designed line, the direction indicated by 1 is not pierced, and one-third of the thickness of the substrate is retained, and the other direction needs to be pierced, and the ceramic substrate is cut into long strips.

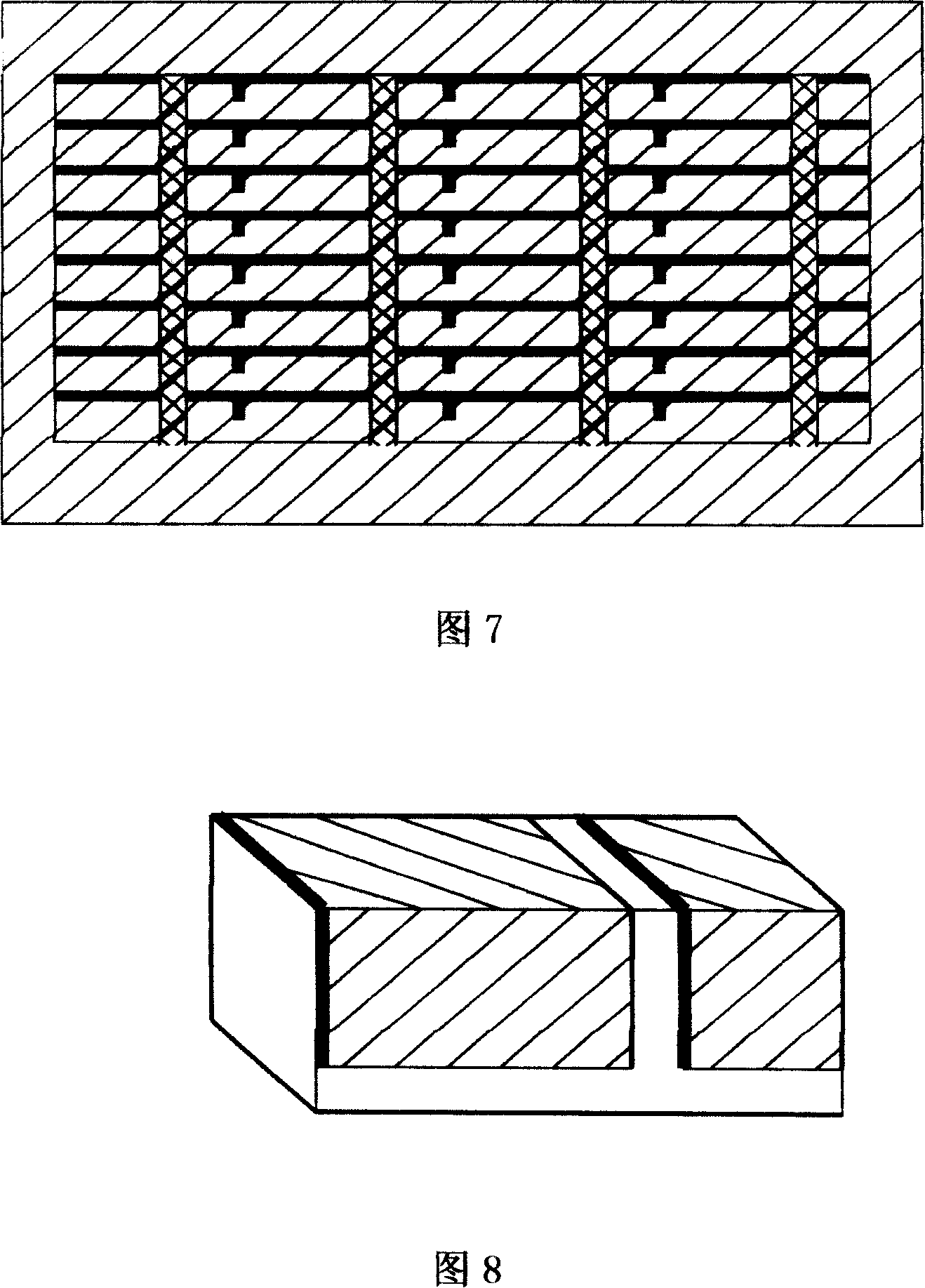

[0009] Figure 4. According to the design requirements, the strips after being divided should face up the specific side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com