Device and method for improving screen printing precise alignment by using contact photoetching machine

A technology of screen printing and precise alignment, applied in the directions of printing device, printing, tin feeding device, etc., to achieve high-precision alignment, improve alignment accuracy, and broaden the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

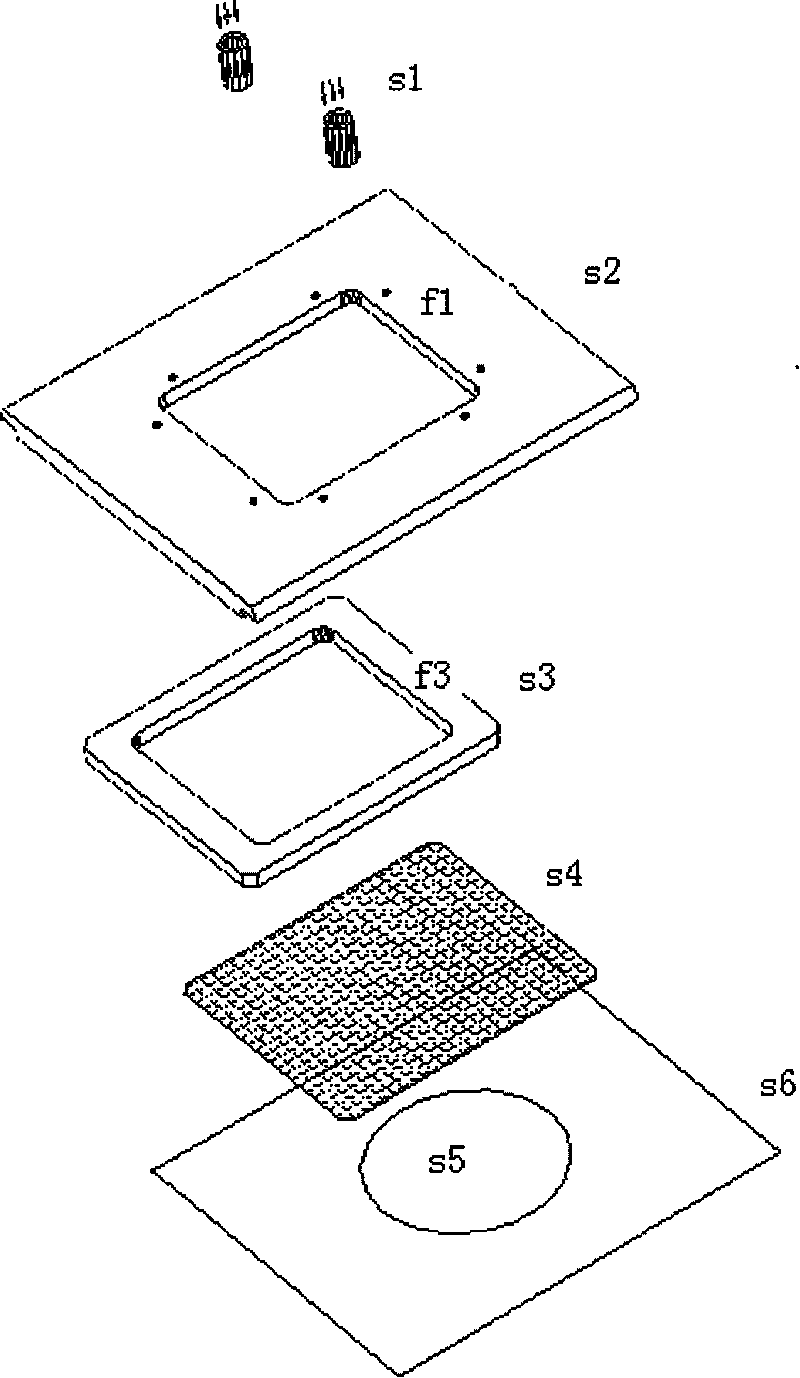

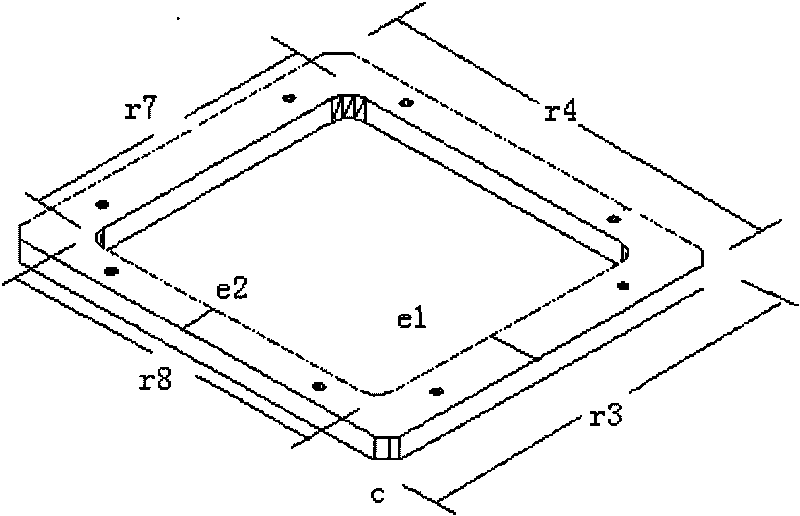

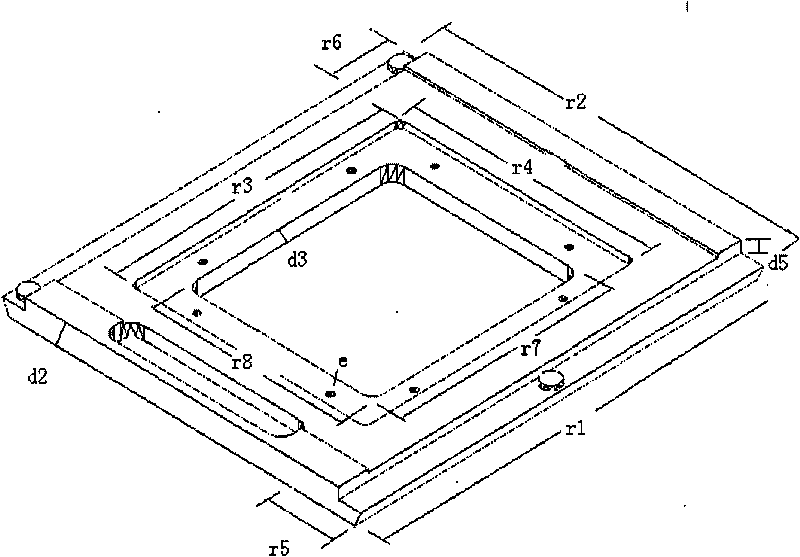

[0013] Control attached figure 1 , the auxiliary positioning fixture is made of aluminum alloy, and its thickness is determined according to the structure of the photolithography machine. The screen s4 is firmly adhered to the lower surface f4 of the screen frame through Nanbao resin, and the upper surface f3 of the screen frame is connected with the screw structure. The positioning jig frames s2 are connected together to form a screen printing jig. Through the design of the screw structure, the positioning fixture frame s2 and the movable screen frame s3 form a detachable structure, which can replace the lithography plate fixture of the contact lithography machine and be loaded into the lithography machine. The microscope alignment system of the lithography machine, under the lithography machine is the wafer holder, and the precise positioning of the screen pattern and the wafer is performed through the principle of compressed air positioning and alignment of the lithography ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com