Positioning advancing system specially for servo direct-spraying machine for spraying and printing gold, silver, copper, iron and aluminum

A copper-iron-aluminum, direct-injection technology, used in printing, typewriters, printing devices, etc., can solve problems such as inability to continuously print, and achieve the effects of high positioning accuracy, stable operation, and adjustable printing height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

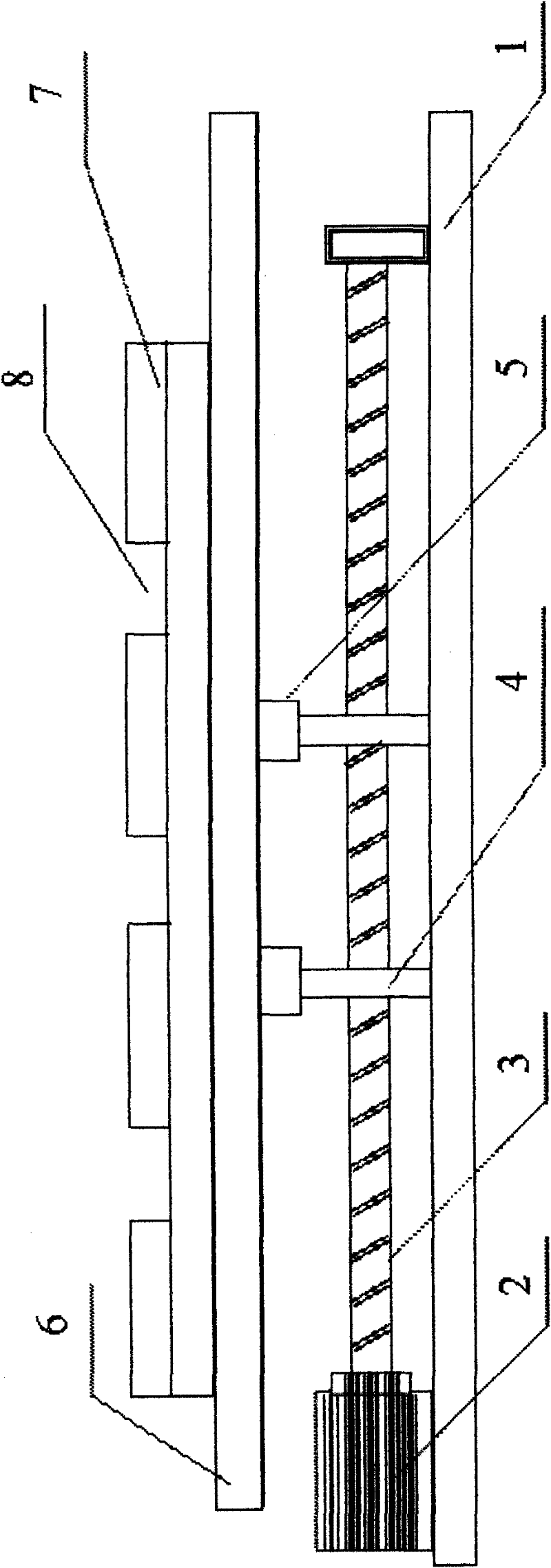

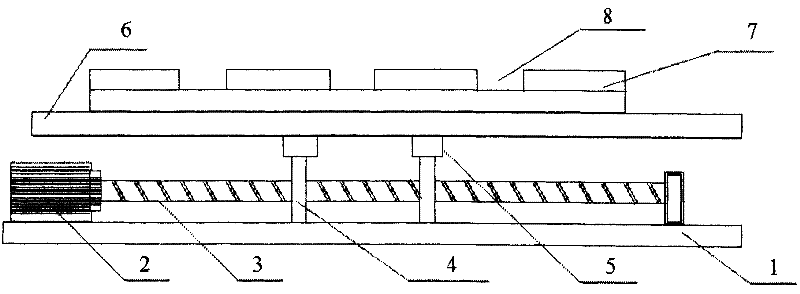

[0007] Such as figure 1 A positioning advance system of a servo direct injection machine dedicated to printing gold, silver, copper, iron and aluminum is shown, including a base chute (1), a servo motor (2), a screw screw (3), a screw sleeve (4 ) and the fixed piece (5) driven by the screw sleeve (4), the servo motor (2) is connected with the screw sleeve (4) through the helical screw (3), and the screw sleeve (4) is installed on the base chute ( 1), the printing platform (6) is fixed on the fixing part (5), and four positioning grooves (7) are fixed on the printing platform (6) in an equidistant arrangement, and between each product positioning groove (7) There are product templates (8) that can be placed in between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com