Differential scanning calorimeter and manufacturing method thereof

A technology of differential scanning calorimetry and manufacturing method, which is applied in the field of measurement, can solve the problems of large time constant of the instrument, heat transfer lag, unfavorable improvement of resolution, etc., and achieve the effect of small heat capacity, high sensitivity, and small time constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following description of the exemplary embodiments is illustrative only and in no way serves as any limitation of the invention and its application or use. Techniques known in the art may be applied to parts not particularly shown or described.

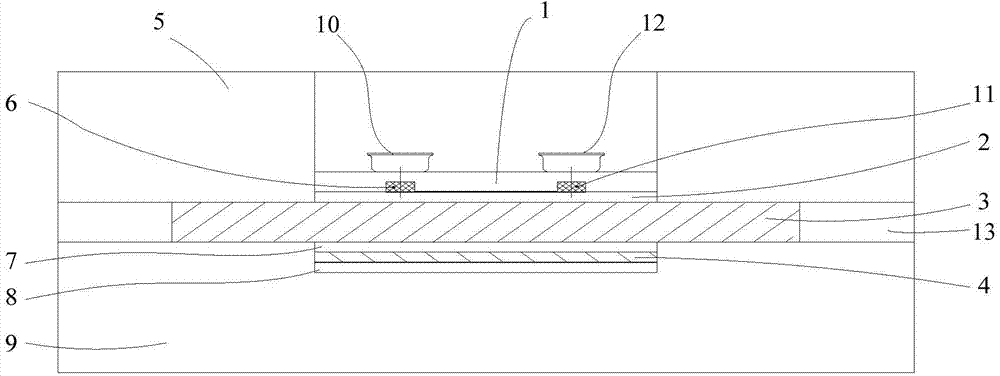

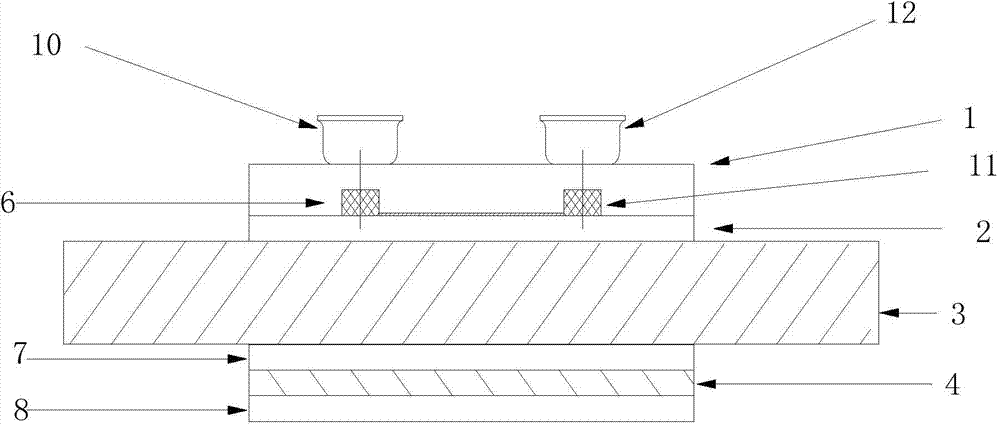

[0035] Such as figure 1 As shown, the present invention provides a differential scanning calorimeter, comprising a main body core formed by a thick film process and a heat insulating layer disposed outside the main body core. The core part of the main body includes: a conductive layer 3; a first insulating layer 2, a sensor layer and a second insulating layer 1 arranged on one side of the conductive layer 3 in sequence, and the second insulating layer 1 completely covers the sensor layer ; The third insulating layer 7 , the heating layer 4 and the fourth insulating layer 8 are sequentially arranged on the other side of the conductive layer 3 . The first insulating layer 2, the sensor layer, the second insulating layer 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com