Device for regulating the operating pressure of an oil-injected compressor installation

A working pressure and compressor technology, applied in the field of working pressure devices, can solve the problems of staying in the pipe, compressed air loss, large input loss, etc., to achieve the effect of small time constant, easy realization, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

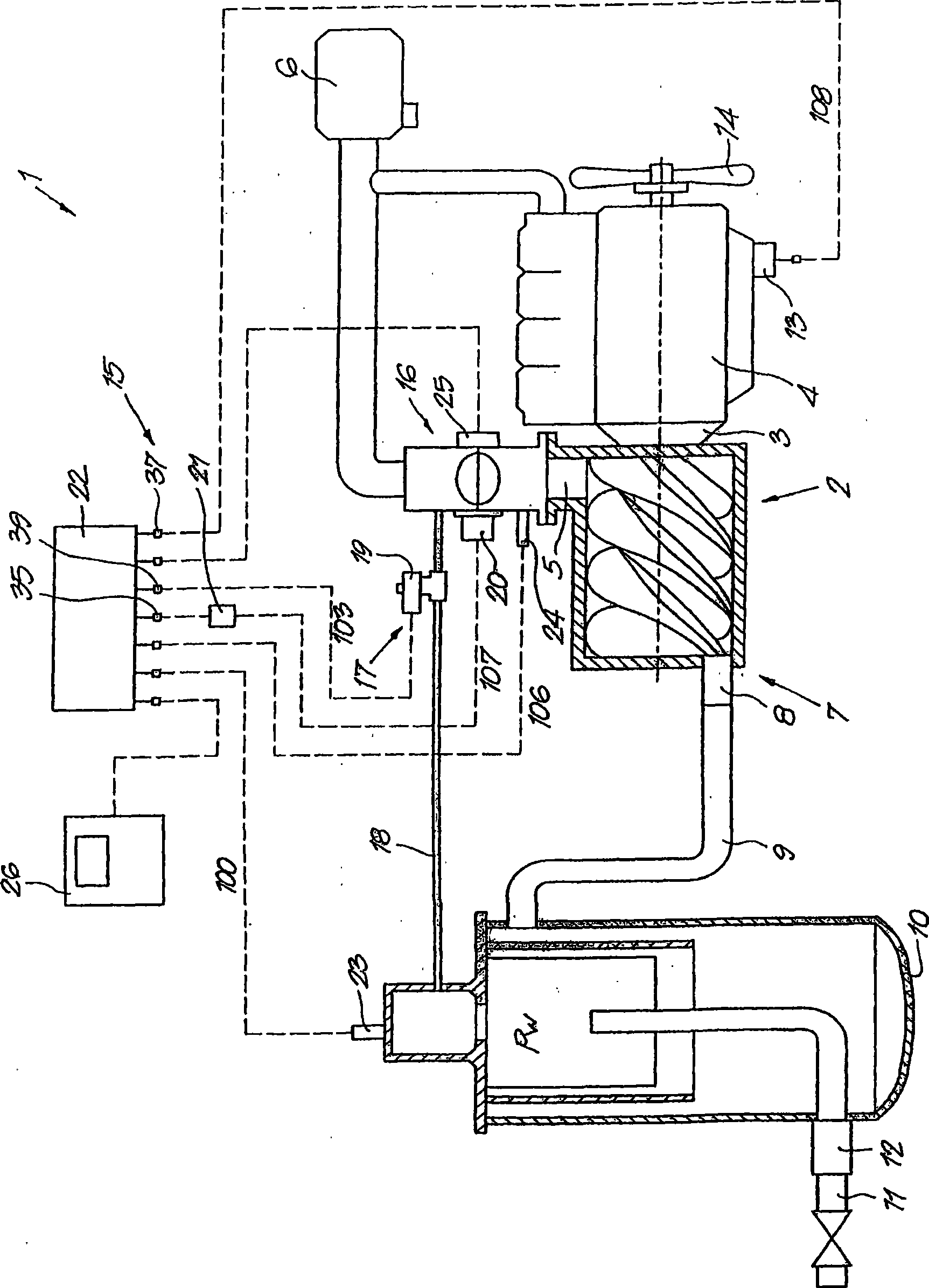

[0031] figure 1 A compressor device 1 is schematically depicted, which in this case is made in the form of an oil-injected screw compressor, which is provided with a compressor element 2 via a transmission 3 Driven by motor 4 with adjustable speed.

[0032] The compressor element 2 is provided with an air inlet 5 for introducing the gas to be compressed via an air filter 6 and a compressed air outlet 7 which opens through a non-return valve 8 in a duct 9 which is connected to a known type of oil separator 10.

[0033] Via a compressed air line 11, which is connected to the aforementioned oil separator 10 via a minimum pressure valve 12, the user of compressed air can take compressed air with a certain working pressure Pw and feed it, for example, into a compressed air network or the like .

[0034] The above-mentioned oil separator 10 passes through the injection pipe (not in figure 1 shown in ) is connected to an injection valve provided on the compressor element 2 to inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com