Automatic revolving table for robot teeming line

An automatic rotary and pouring line technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems of small load, unguaranteed, inability to meet the accuracy of pouring mold shell placement and positioning, and save time , save manufacturing cost, increase the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

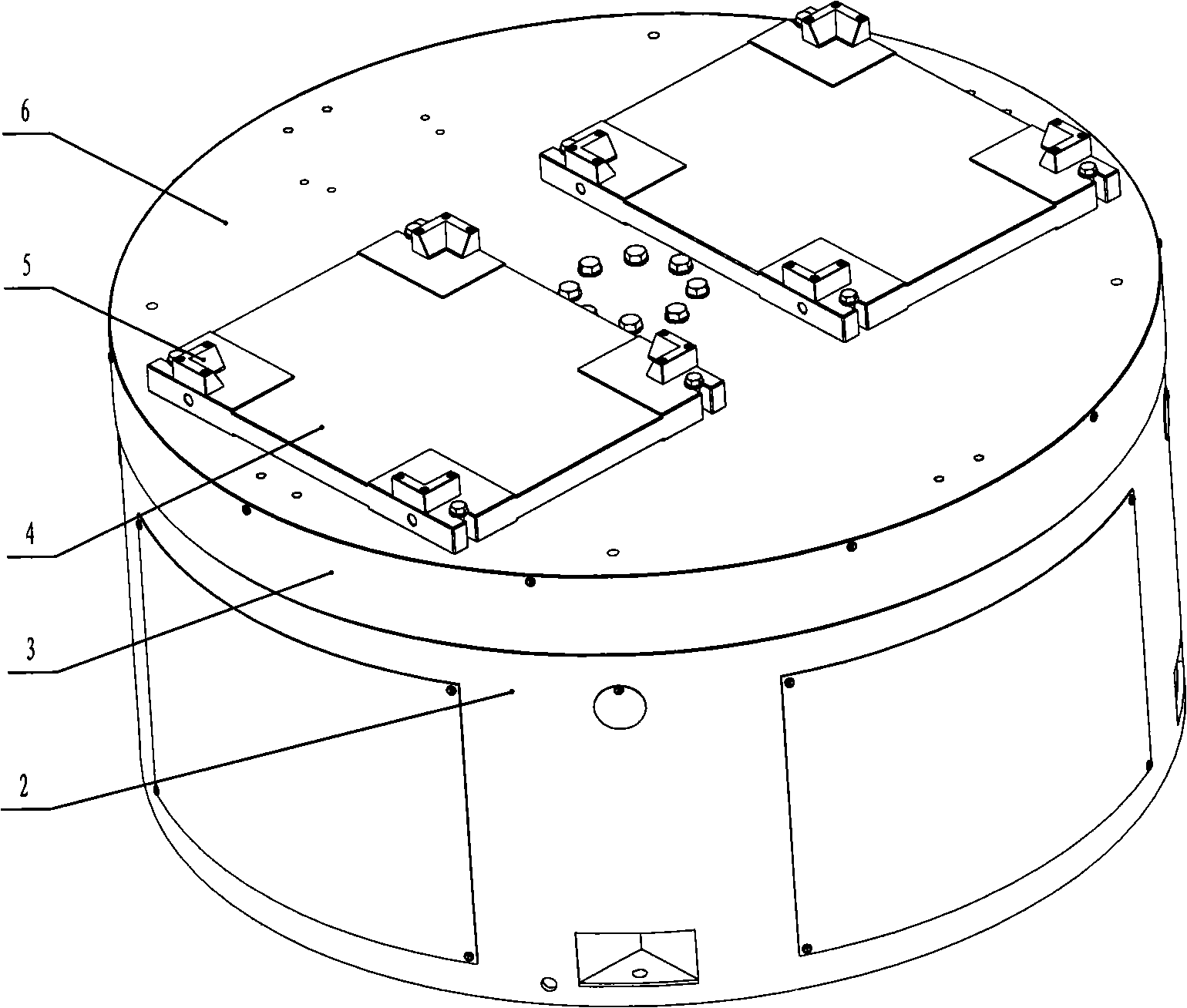

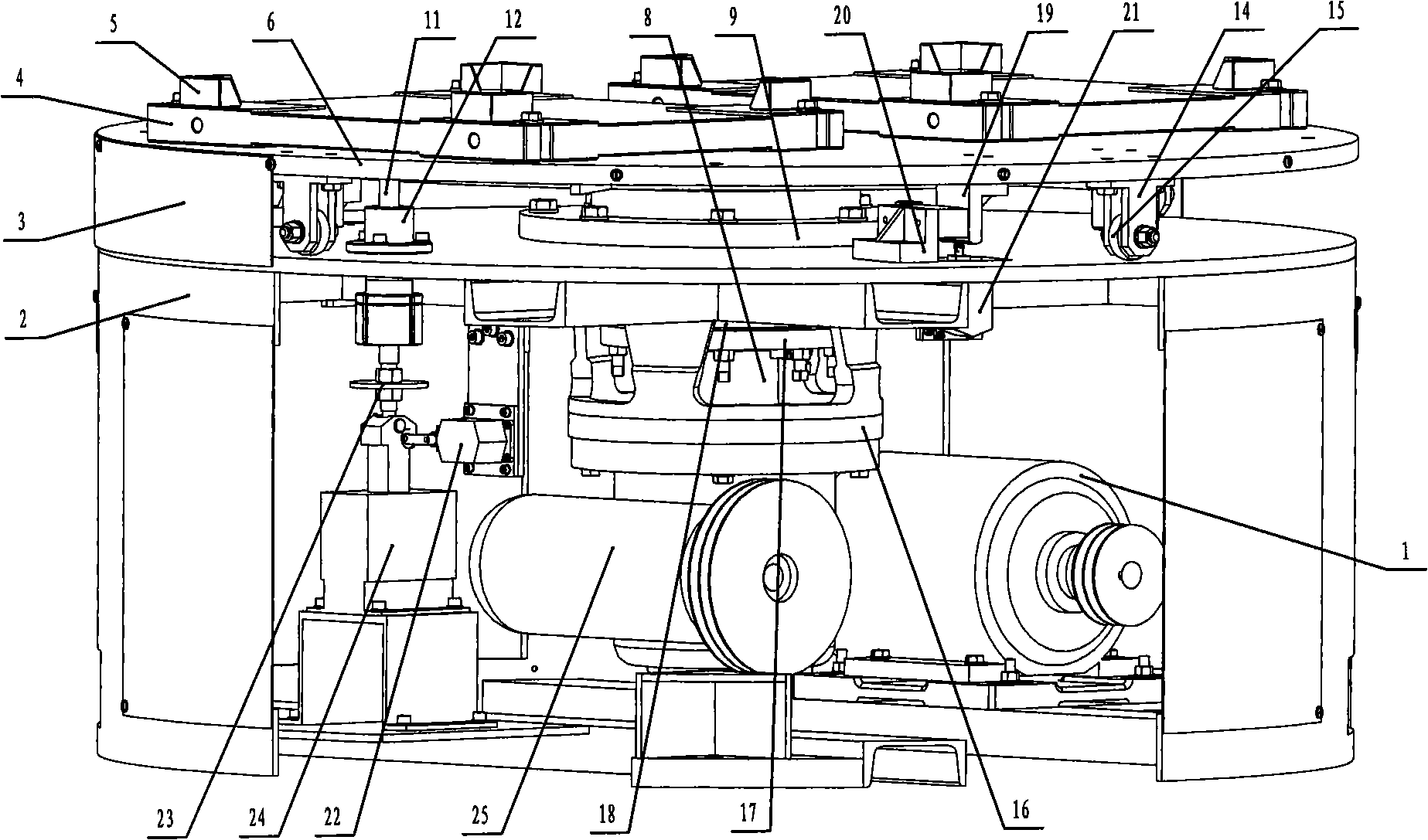

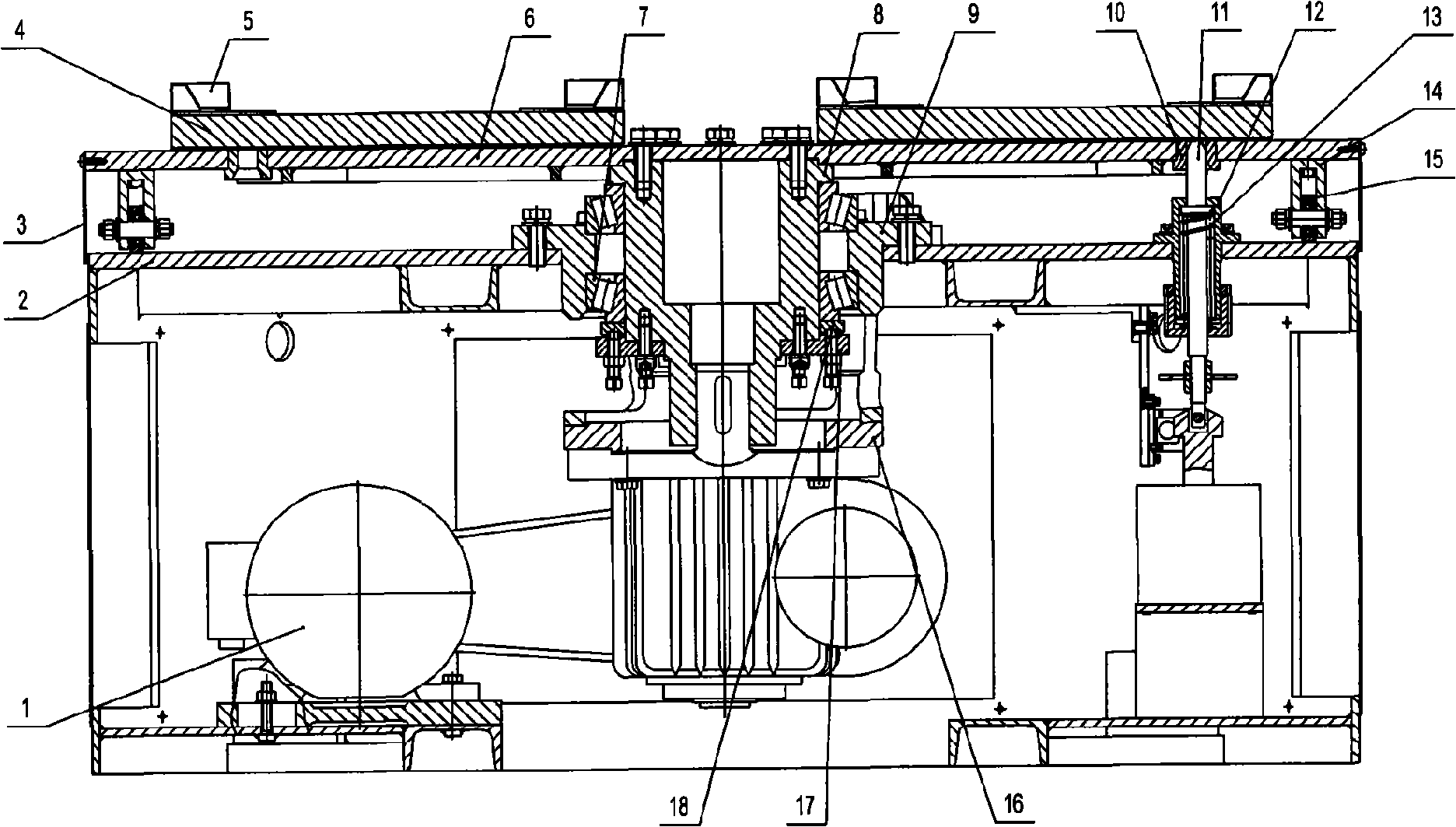

[0019] Figure 1 ~ Figure 4 As shown, it includes motor 1, base 2, platform outer shield 3, box positioning base 4, box positioning block 5, rotary table turning surface 6, tapered roller bearing 7, main rotary shaft 8, bearing seat 9, positioning Guide sleeve 10, positioning guide rod 11, positioning guide rod seat 12, spring 13, auxiliary support 14, auxiliary support roller 15, reducer connecting flange 16, bearing gland 17, bearing pressure plate 18, iron stopper 19, buffer Block support 20, plunger roller type travel switch 21, single-wheel travel switch 22, single-wheel travel switch strike plate 23, traction electromagnet 24, worm gear reducer 25.

[0020] In the present invention, the motor 1 is connected to the base 2 through the motor bottom plate; the bearing seat 9 is connected to the base 2, fastened with screws, and guaranteed to be coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com