Locking double-end stud assembly structure with stopping station

A double-ended stud and component structure technology, applied in the direction of locking fasteners, threaded fasteners, screws, etc., can solve the problems of unreasonable structural design and scrapping of special fasteners for connection and anti-loosening, and achieve a qualified rate Improve and ensure the assembly requirements, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

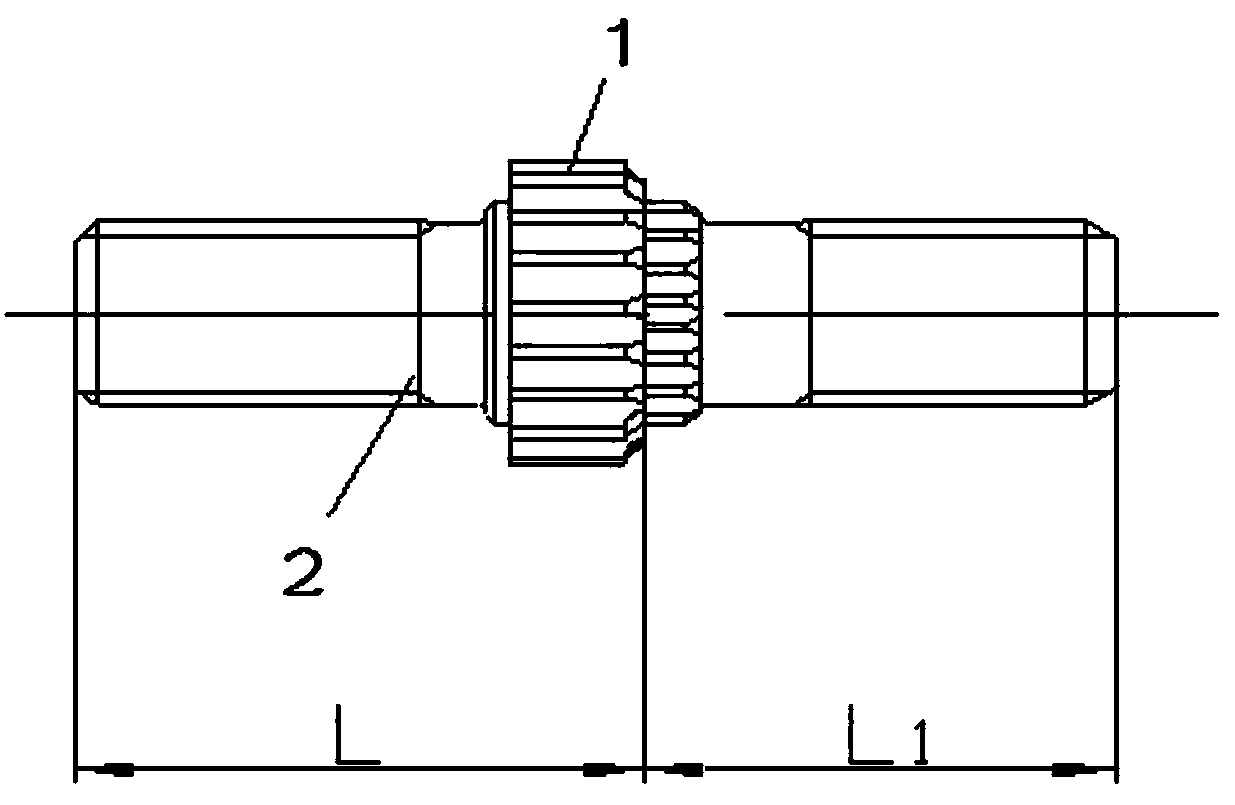

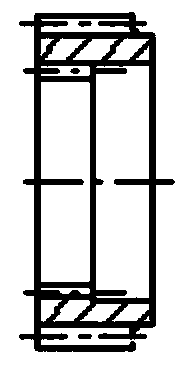

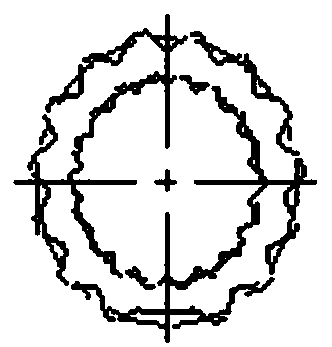

[0015] Refer to attached Figure 5 , this embodiment provides a locking stud assembly structure with a stop table, including a locking ring 1 and a stud 2, the middle of the stud 2 is processed with straight teeth 21 along the circumferential direction, straight One end of the tooth 21 is processed with a stopper 22. Both the straight tooth 21 and the stopper 22 are integrated with the stud 2. Structure, the root of the connection between the stopper 22 and the straight tooth 21 is provided with an undercut 23, the width of the undercut 23 is 0.4-0.5mm, and the size of the bottom of the undercut 23 is 0.05 smaller than the small diameter of the straight tooth 21 -0.1mm, that is, the groove bottom depth of the undercut groove 23 is 0.05-0.1mm smaller than the minor diameter of the straight tooth 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com