Machining method of cabin section work-piece

A processing method and workpiece technology, which is applied in the processing field of cabin workpieces, can solve problems such as slag falling, workpiece quality and accuracy cannot be guaranteed, and processing deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

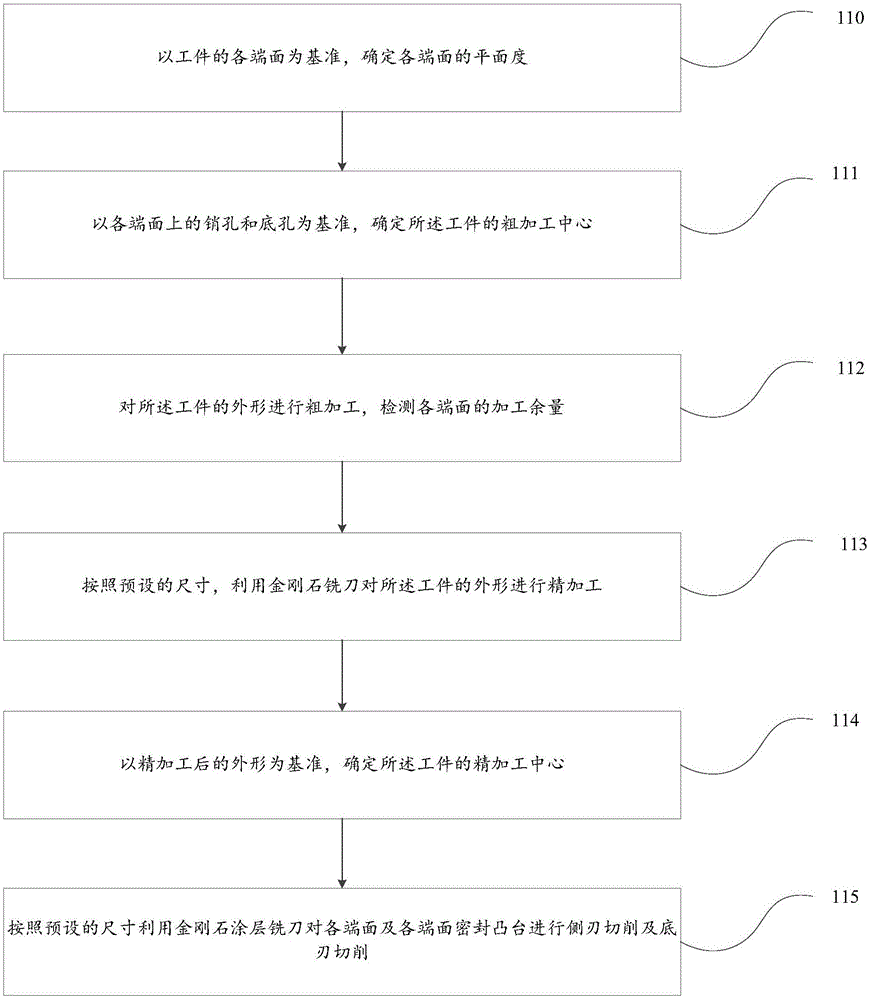

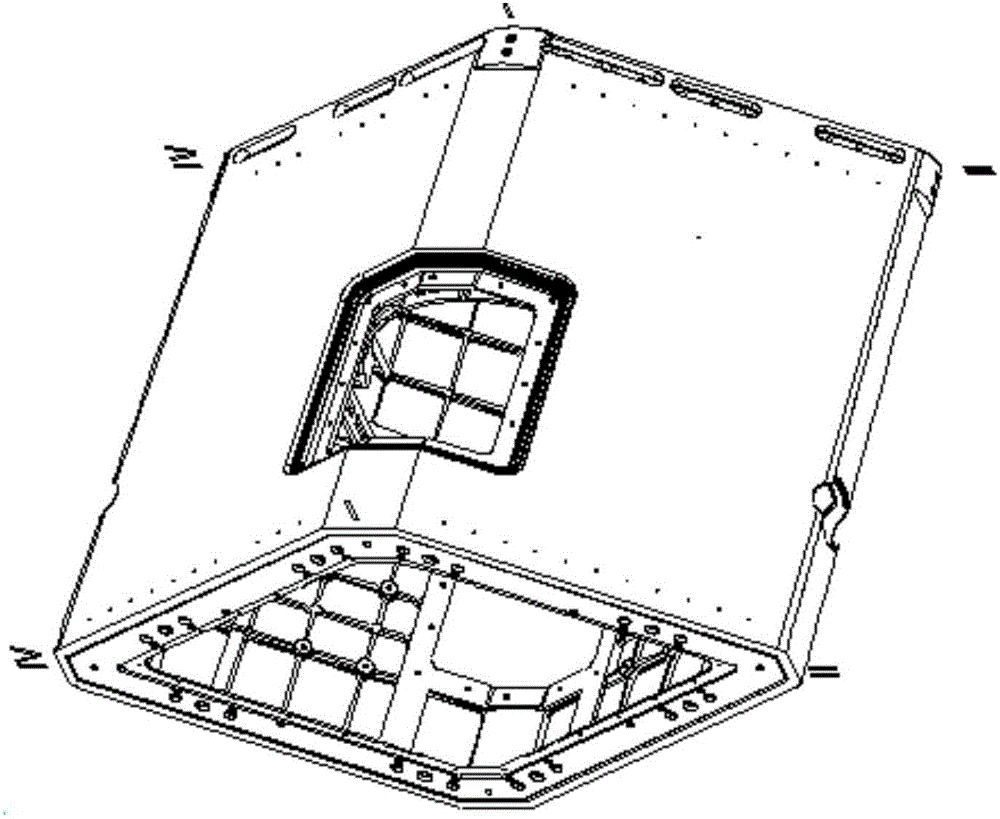

[0041] In order to solve the technical problems that the quality and precision of the workpiece cannot be guaranteed because of the processing deformation, uneven wall thickness of the heat-proof layer, slag falling and blockage, etc., when processing the cabin workpiece of the ceramic composite matrix, the invention provides a A method for processing a cabin workpiece, the workpiece includes an end surface, and the end surface is provided with a notch, and the method includes: taking each end surface of the workpiece as a reference, determining the flatness of each end surface; Determine the rough machining center of the workpiece based on the pin hole and bottom hole on the upper surface; rough machine the shape of the workpiece, and detect the machining allowance of each end face; according to the preset size, use a diamond milling cutter to The shape of the workpiece is finished; based on the finished shape, the finishing center of the workpiece is determined; according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Minor axis length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com