Precise scribing method for thin-wall special-shaped casting cabin

A technology for casting cabins and special shapes, applied in the field of machining, can solve problems such as uneven wall thickness of parts, achieve the effects of uniform wall thickness, great economic benefits, and effectively control the problem of uneven wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

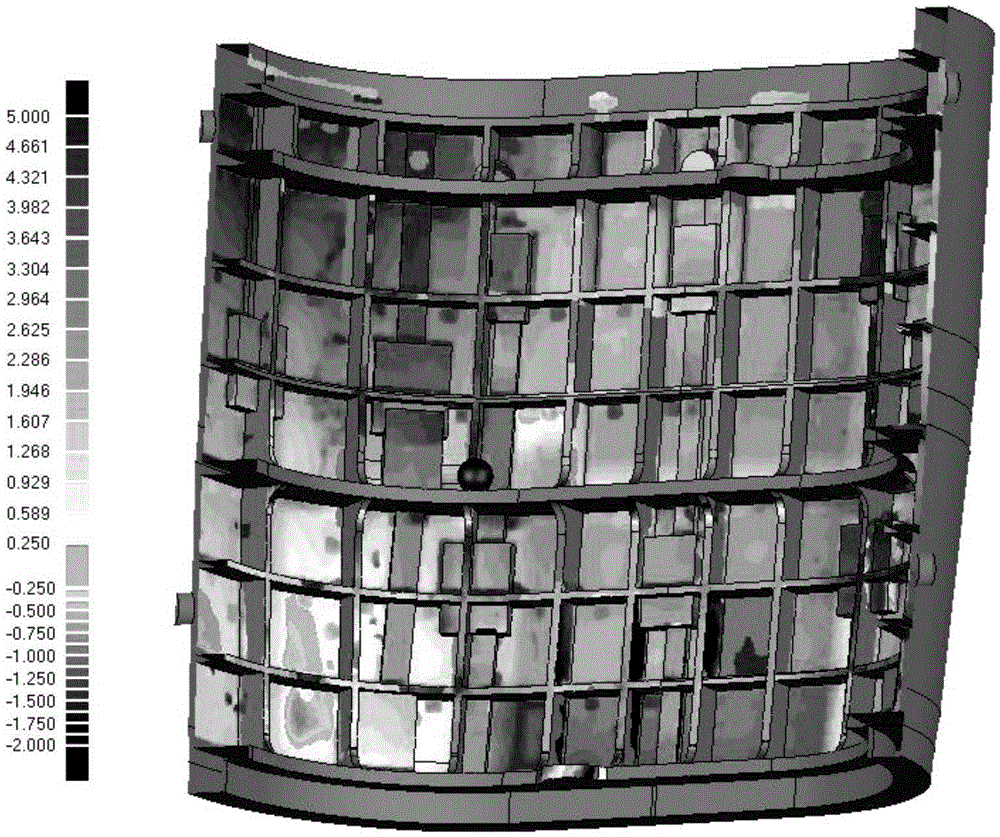

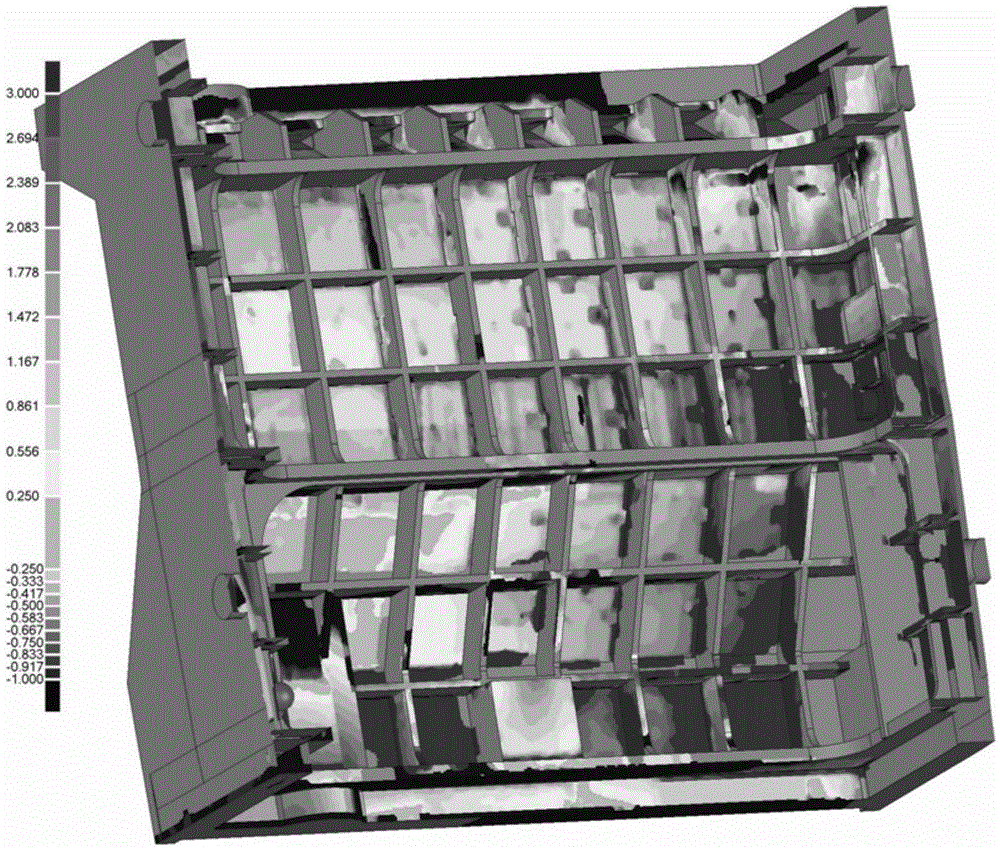

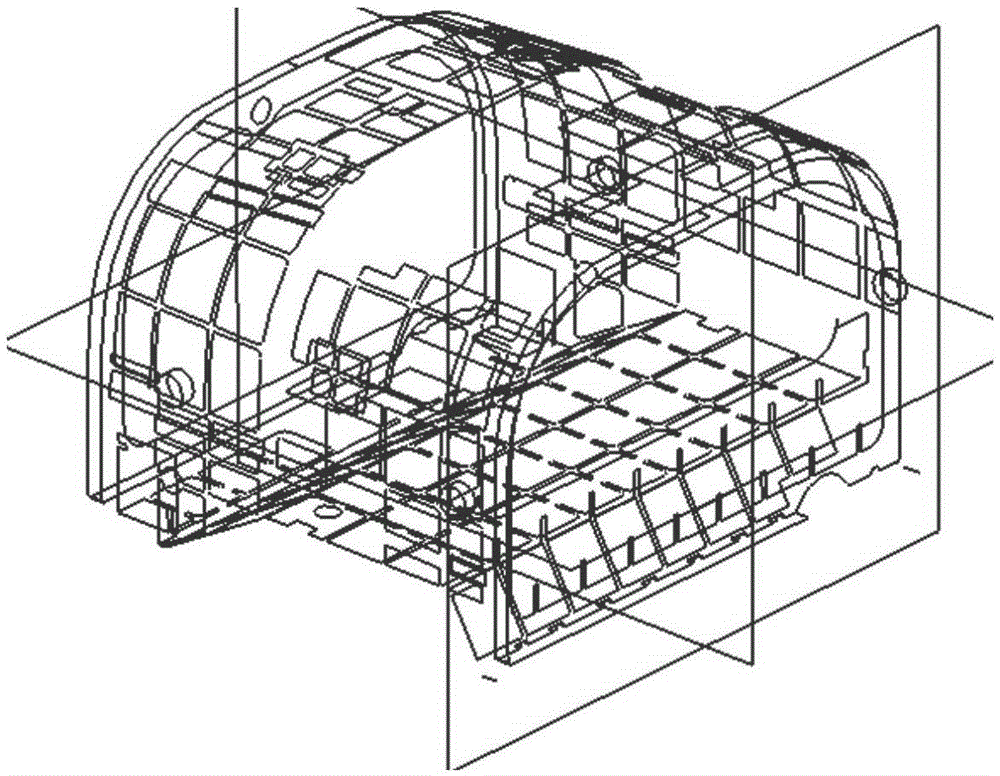

[0024] The precision scribing method of the thin-wall special-shaped casting cabin described in the present invention adopts the rough scribing method based on the rough outline of the outline to draw the outline processing surface line, and uses the data collection method of scanning the inner cavity surface with a laser measuring machine. The method of establishing the workpiece coordinate system by the cavity point cloud and the method of accurately adjusting the surface line of the exterior processing; the specific steps of the method are as follows:

[0025] Step 1: Reserve a datum boss on the shape of the workpiece when casting the workpiece, and draw the shape processing surface line according to the center position of the datum. The shape processing surface line is a horizontal plane line, a symmetrical plane line, and an end surface line;

[0026] The boss is located on the horizontal plane line, symmetrical plane line, and end surface line of the workpiece. When machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com