Carriage bottom plate drilling locator

A technology of a compartment floor and a locator, which is applied to the measurement of positioning in the boring machine/drilling machine, drilling/drilling equipment, workshop equipment, etc., can solve the problems of increasing the labor intensity of workers, affecting the service life of vehicles, and reducing work efficiency. , to improve work efficiency and maintenance quality, reduce labor intensity and maintenance costs, and eliminate potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiments.

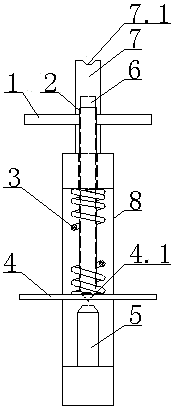

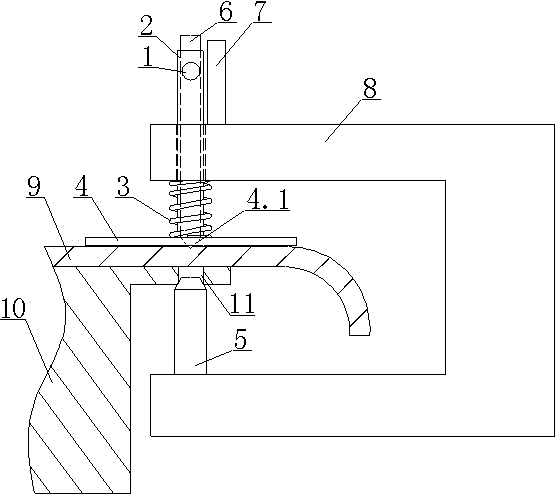

[0018] by figure 1 , 2 It can be seen that the carriage floor drilling locator is composed of a bow-shaped bracket 8, a positioning pin 5, and a punching mechanism. The upper wing of the bow-shaped bracket is provided with a punching mechanism with a sample punch 6, and the lower wing of the bow-shaped bracket sets position pins. The center axis of the punch and the center axis of the positioning pin are on the same vertical line.

[0019] The arch-shaped bracket 8 is an open rectangular frame. The upper wing and the lower wing are parallel and in the same vertical plane. The distance between the two wings of the rectangular frame is greater than the sum of the thickness of the upper wing of the bottom beam 10 and the bottom plate 9; the width of the rectangular frame is adapted to the front end of the bottom plate. The wing is provided with a through hole, a limit baffle 7 is provided n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com