Method for scribing and measuring side frame

A side frame and centerline technology, which is applied in the field of side frame marking measurement, can solve the problems of inaccurate positioning, low precision, and great influence on the technical level of marking workers, so as to achieve the effect of improving accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

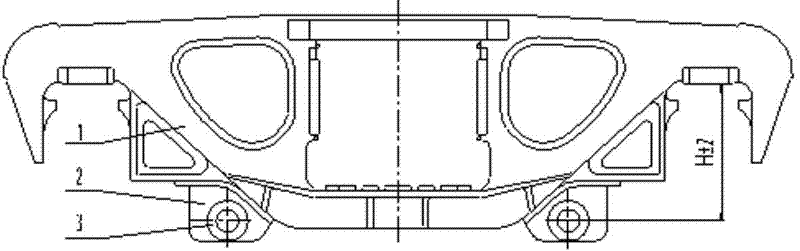

[0065] (1) Measure the distance H1 from the bearing surface of the side frame bearing saddle to the platform.

[0066] produced two such Figure 4 , 5 The stand shown. The two supports have the same height, the upper and lower planes are parallel, and the upper and lower planes are perpendicular to the sides. Put the side frame working position (vertical position) on the support, such as Image 6 shown. At this time, the height of the support is the vertical distance H1 between the bearing surface of the side frame bearing saddle and the platform.

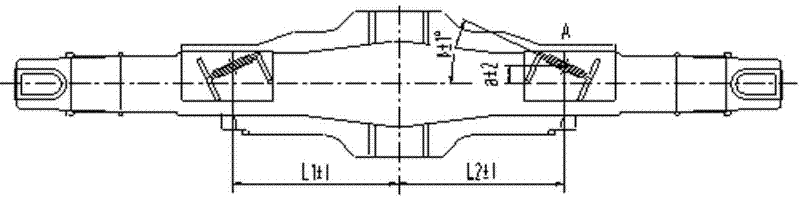

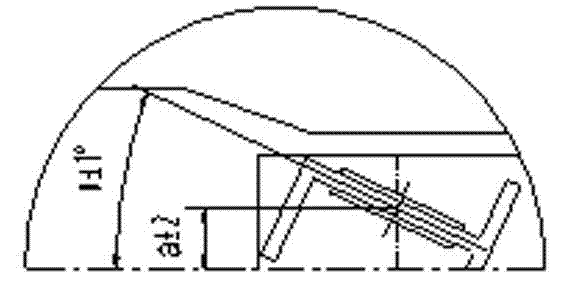

[0067] (2) Measure the distance H from the center of the side frame support seat to the bearing surface of the bearing saddle.

[0068] produced as Figure 7 , Figure 8 Centerline positioning blocks shown. Since the inner hole size of the retaining ring is Φd±0.5mm, in order to ensure the close contact with the retaining ring when making the centerline positioning block, the d dimension is a series size with a taper of 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com