Center measuring device

A measuring device and center positioning technology, which is applied in angle/taper measurement, workshop equipment, manufacturing tools, etc., can solve the problems of high influence on the technical level of line marking workers, low work efficiency, and long time consumption, so as to improve the center line marking. Line efficiency, improve center line marking accuracy, and solve the effect of marking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

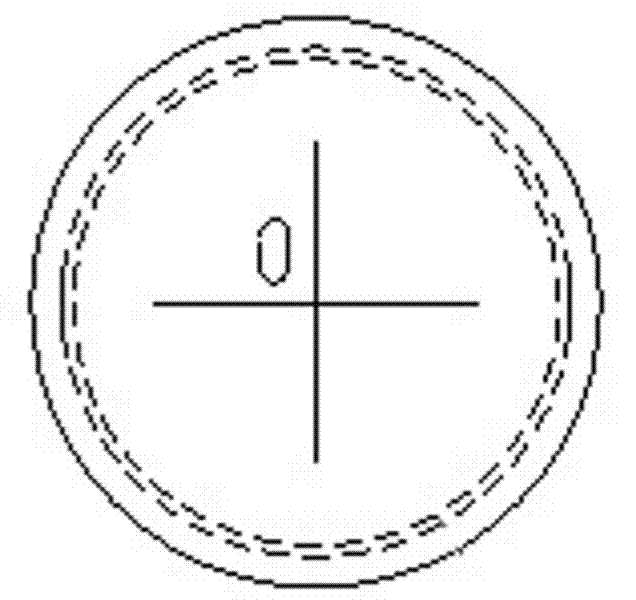

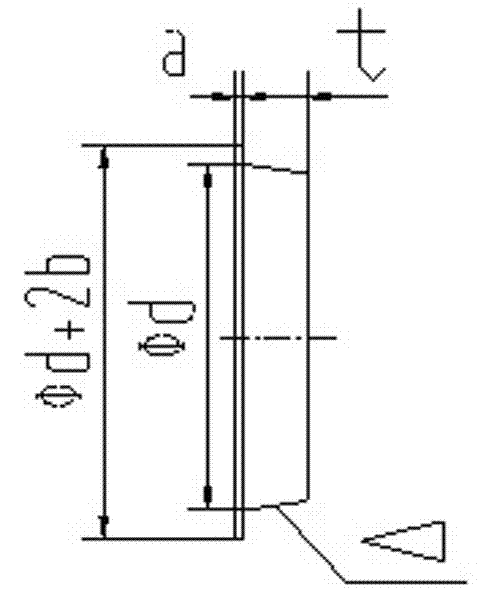

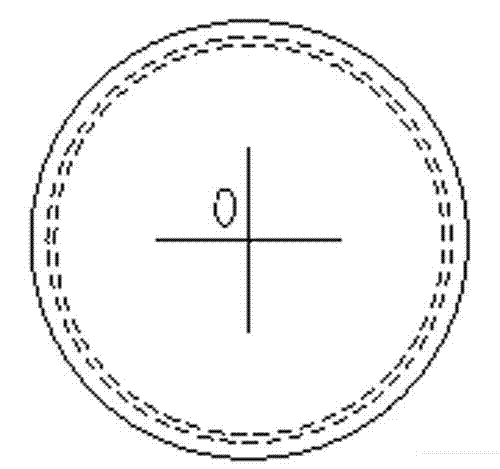

[0025] The center positioning block is used to automatically measure the center of rotary parts. figure 1 , figure 2 The type I center positioning block shown is suitable for hole parts, image 3 , Figure 4 The type II center positioning block shown is suitable for shaft parts. The center measuring device includes a type I center positioning block 1 and a type II center positioning block 3. Both the type I center positioning block 1 and the type II center positioning block 3 include a cone that can cooperate with the measured part, and the top of the cone is set concentrically with it. The top platform of the top platform, the center of the top platform is provided with a cross line, and the intersection point of the cross line is consistent with the center of the top platform. The cone is a platform with a tapered inner hole. The top platform of Type I central positioning block 1 is provided with an annular rib protruding relative to the cone.

[0026] The function of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com