Sliding rail type automatic lineation ruler and method

An automatic scribing and sliding rail technology, applied in the field of mechanical processing, can solve problems such as inaccurate scribing, affecting production efficiency, and wasting manpower, so as to reduce errors and human uncontrollable factors, improve scribing accuracy, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A slide rail type automatic marking ruler

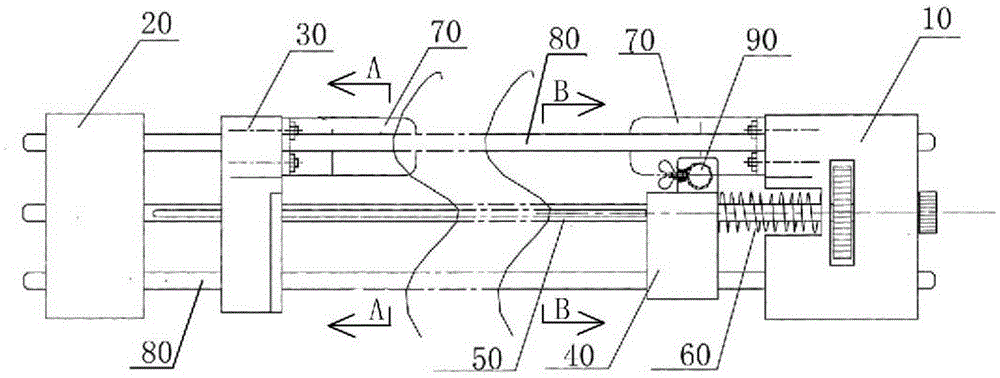

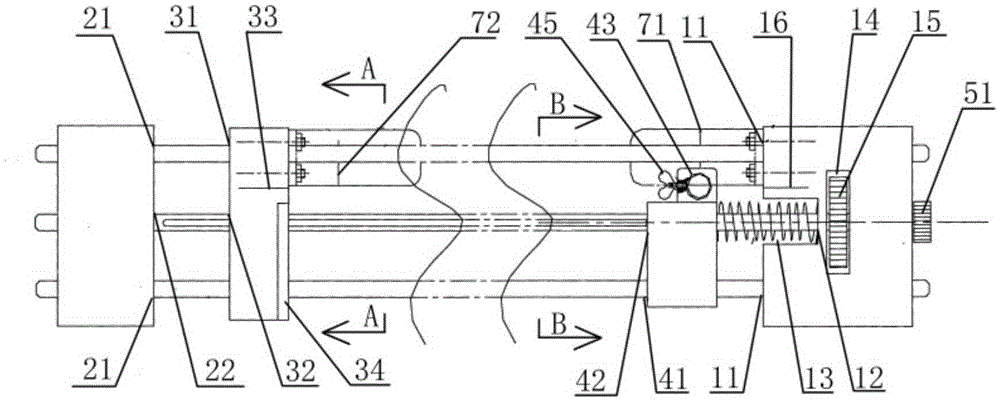

[0041] Such as Figure 1-Figure 8 As shown, a slide rail type automatic marking ruler has the following structure:

[0042] There is a component I10 for support, the two ends of the component I10 are respectively provided with a configuration rod assembly hole I11, the middle part is provided with a cross slide rod assembly hole I12 and a spring groove 13, and a through hole is provided on the end surface 14. Knob II15 is installed in the through hole 14. The component I10 is provided with a horizontal reference line I16.

[0043] There is a member II20 for supporting, the two ends of the member II20 are respectively provided with a configuration rod assembly hole II21, and the middle part is provided with a cross slide rod assembly hole II22.

[0044] There is a positioning slider 30 for scribing positioning, and the positioning slider 30 is provided with a configuration rod assembly hole III31, a cross slide ...

Embodiment 2

[0050] Embodiment 2 A sliding rail type automatic marking method

[0051] Utilize the slide rail type automatic marking ruler of embodiment 1, method is as follows:

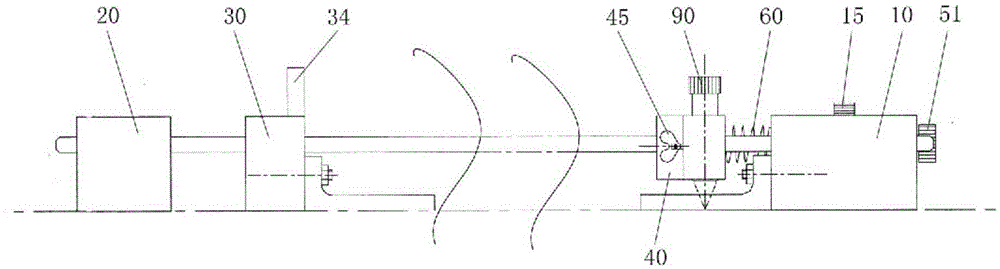

[0052] 1) Create the driving force for scribing

[0053] Place the slide-rail type automatic marking ruler on a horizontal surface, push the marking slider 40 to the side of component I10, and compress the spring 60 until the marking slider 40 slides over the raised part 53 in the middle section of the cross slide bar 50, and rotates Knob I51 displaces the protrusion 53 from the sliding groove 44, and blocks the marking slider 40.

[0054] 2) Correct the pen tip marking track

[0055]Place the marking pen 90 in the pen hole 43 of the marking slider 40, press down on the marking pen 90, make the marking pen 90 lean against the inner edge of the marking correction sheet 70, adjust the position of the pen tip on the member I10 On the extension line of the horizontal reference line Ⅰ16, tighten the knob Ⅲ45 to fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com