Die cavity structure, die design method, blowing method and blowing control system

A design method and control system technology, applied in household appliances, other household appliances, hollow objects, etc., can solve problems such as inconsistent radial displacement, difficulty in realization or control, and uneven wall thickness, so as to slow down the plastic ductility and increase Partial wall thickness, the effect of uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

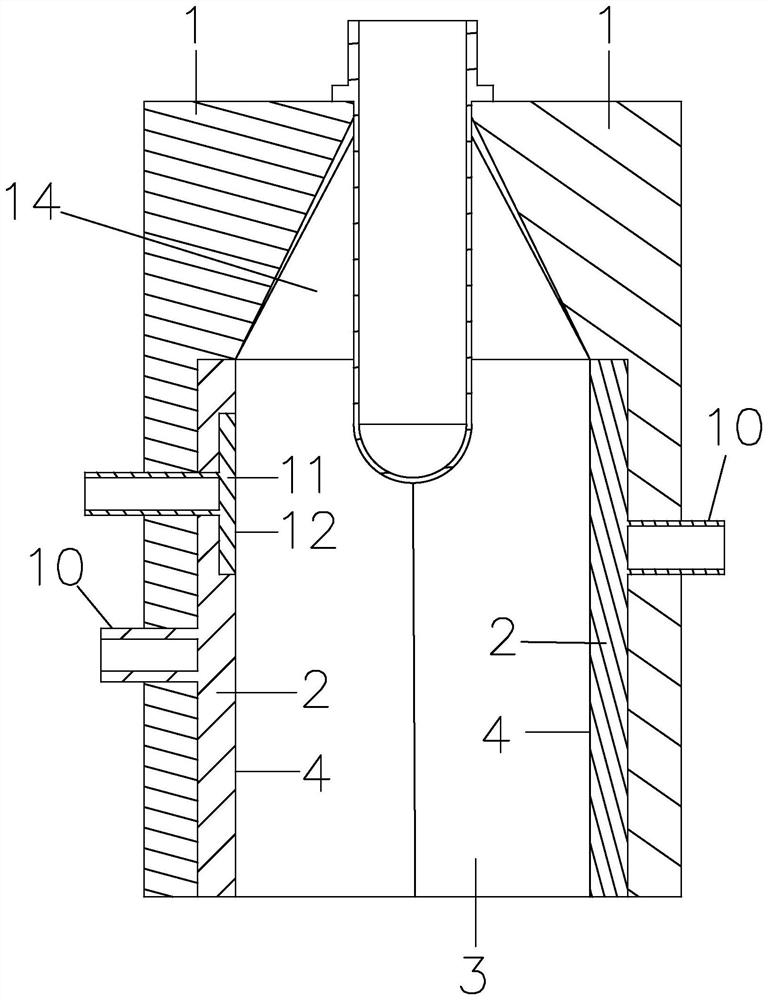

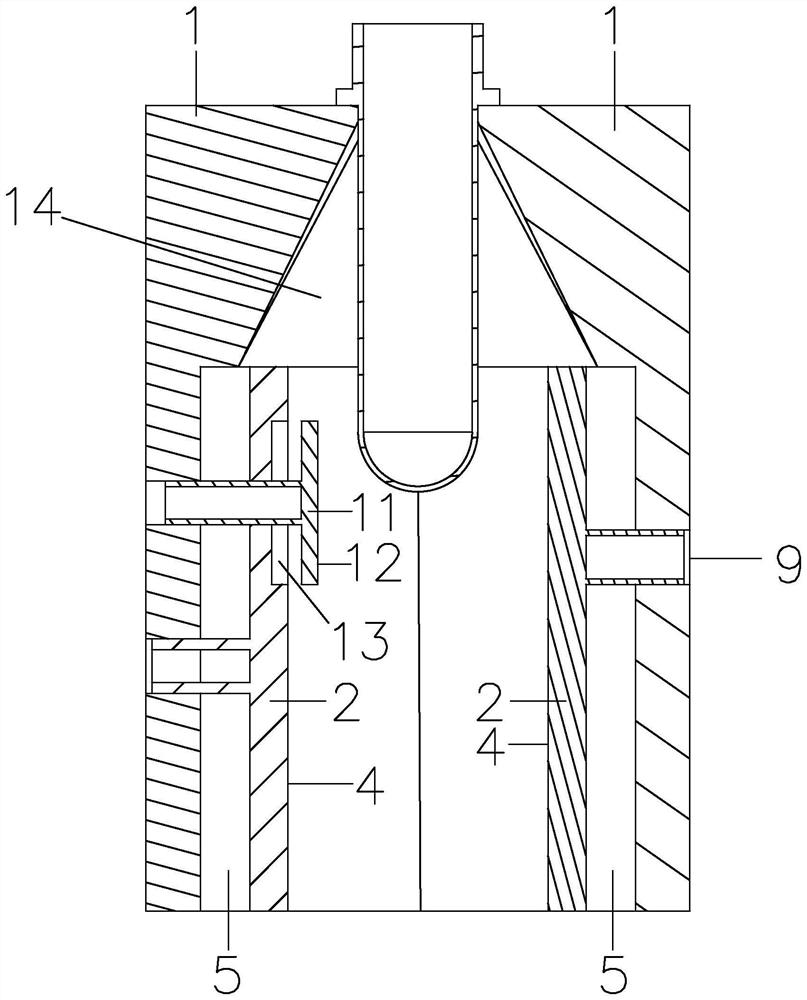

[0053] like Figure 1 to Figure 19 As shown, the present embodiment discloses a cavity structure comprising a cavity half-mold 1 and at least one first insert 2 combined to form the cavity body, the cavity half-mold 1 having a first part defining the shape of the main body of the container at least A molding surface 3, the first insert 2 has at least a part of the main body shape defining the container A second molding surface 4, the first insert 2 has at least a first position initially protruding into the cavity body and a retracted The second molding surface 4 defines a second position of the shape of the part of the main body; wherein the first position of the first insert 2 cannot affect the placement of the preform into the mold cavity, and the distance between the first position and the central axis of the mouth of the preform should be greater than that of the container The radius of the blank.

[0054] As a further improvement of the present invention, the mold cavity ...

Embodiment approach

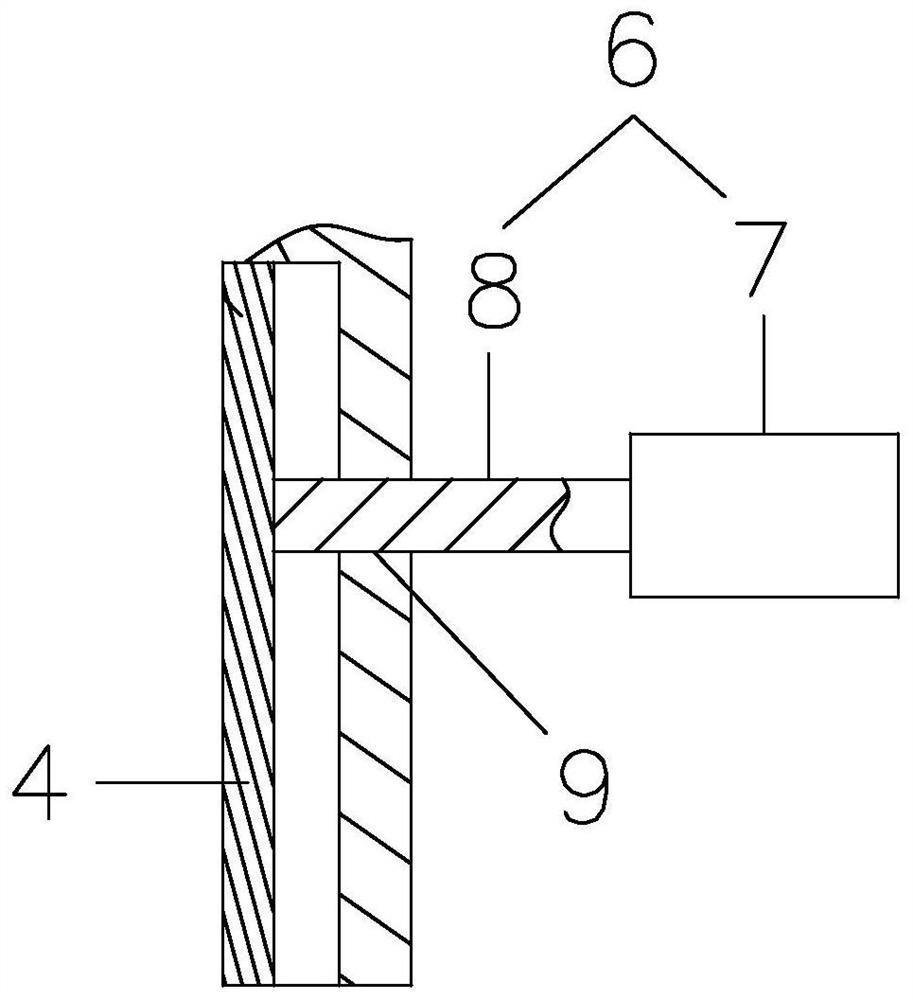

[0058] Mode 1, both ends of the spring 19 are directly connected to the back of the first insert 2 and the bottom of the first accommodating groove 5 respectively.

[0059] Method 2: The bottom of the first accommodating groove 5 is provided with a first blind connection hole 20 for the end of the spring 19 to be embedded and fixed. The diameter of the first blind connection hole 20 is the same as the outer diameter of the corresponding end of the spring 19 Adaptation; the back of the first insert 2 is provided with a second blind connection hole 21 for the end of the spring 19 to be embedded and fixed, and the aperture of the second blind connection hole 21 is compatible with the outer diameter of the corresponding end of the spring 19 Matching; thus facilitating the connection of the spring 19.

[0060] Mode 3: A guide structure is added. The bottom of the first accommodating groove 5 is provided with a guide hole 22 along the telescopic direction of the first insert 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com