A tool for heat treatment and shaping of large blades

A large blade and tool technology, applied in the field of large blade heat treatment and shaping tools, can solve the problems that the blade cannot meet, there is internal stress, blade rebound, etc., to achieve stable and lasting clamping effect, improve processing quality, and ensure the effect of assembly requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

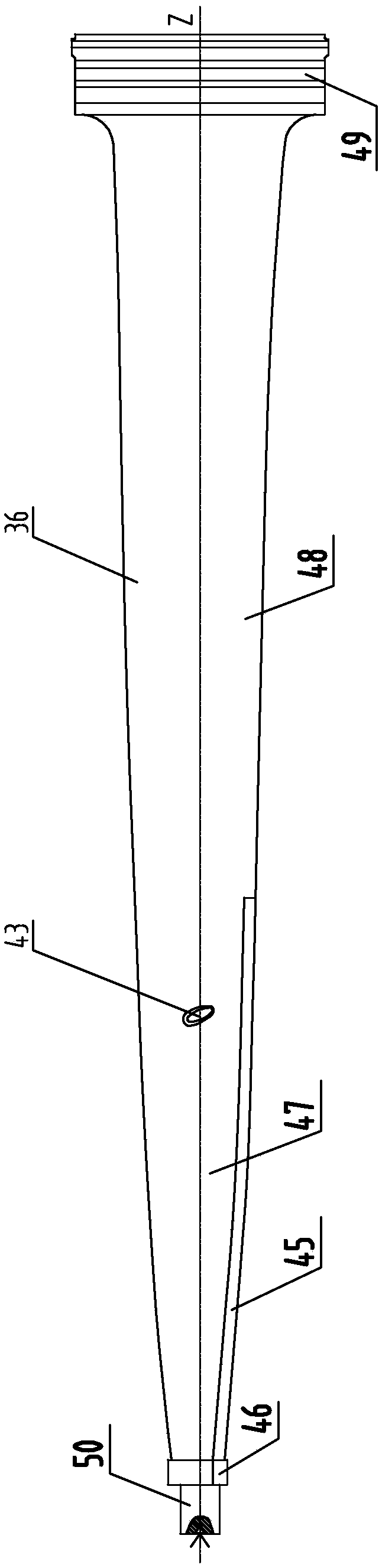

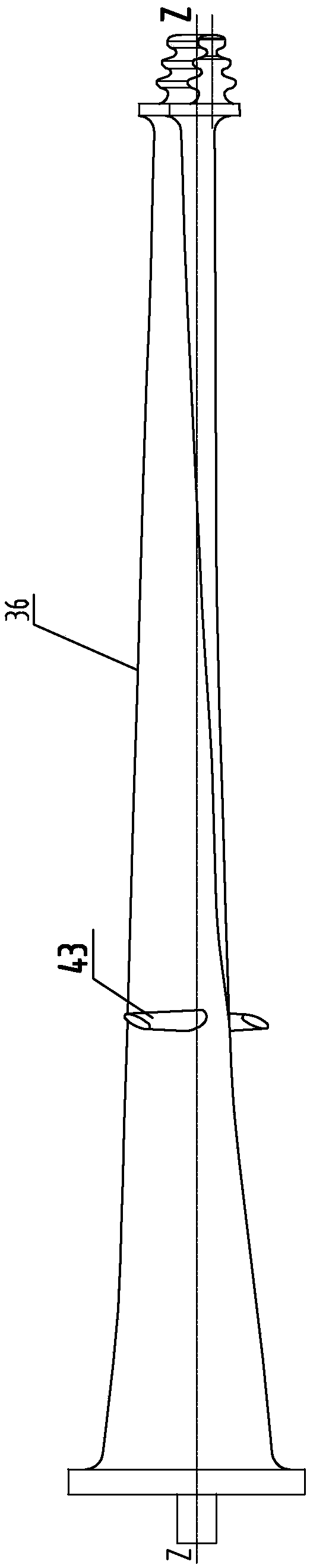

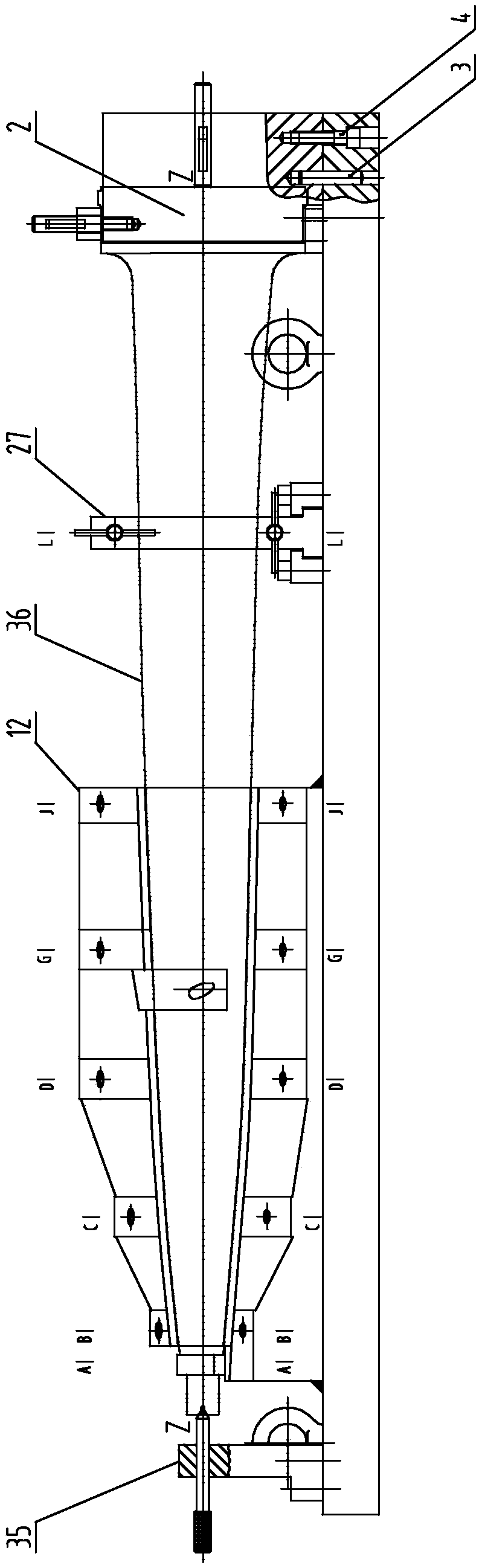

[0031] Specific implementation mode one: combine Figure 1 to Figure 15 Describe this embodiment, this embodiment includes bottom plate 1, blade root positioning seat 2, L profile line positioning block 27, profile line positioning seat 12 and blade crown thimble seat 35, described bottom plate 1 is horizontally set, and described blade root positioning Seat 2, L profile line positioning block 27, profile line positioning seat 12 and leaf crown thimble seat 35 are sequentially arranged on base plate 1 along the length direction of base plate 1, and large blade 36 is arranged on blade root positioning seat 2, L profile profile line Between the positioning block 27, the molded line positioning seat 12 and the leaf crown thimble seat 35, the leaf crown portion 46 of the large blade 36 is pressed against the leaf crown thimble seat 35, and the tendon type line section 47 of the large blade 36 is in phase with the profiled line positioning seat 12. Cooperate with the setting, the a...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination image 3 , Figure 4 and Figure 12 To illustrate this embodiment, the blade root positioning seat 2 is detachably connected to the bottom plate 1 through the blade root positioning assembly. The clamping shaft 11 on the air outlet side, the end of the blade root positioning seat 2 facing the profile line positioning block 27 is processed with a placement groove for the blade root, and the bottom of the blade root positioning seat 2 is detachably connected to the bottom plate 1 through the air intake side positioning block 8, The top of the blade root positioning seat 2 is provided with a blade root outlet side wedge 10 and an outlet side pressure plate 9 sequentially from top to bottom, and the blade root air outlet side clamping shaft 11 passes through the blade root air outlet side wedge 10 and tightens on the air outlet side pressure plate 9 on.

[0038] The structural design of the blade root positioning seat 2 in th...

specific Embodiment approach 3

[0039] Specific implementation mode three: combination image 3 , Figure 4 and Figure 12 To illustrate this embodiment, the bottom of the L profile line positioning block 27 is connected to the base plate 1 through the fixed pressing block 28, and the fixed pressing block 28 is processed with a T-shaped groove that matches the bottom of the L profile line positioning block 27. The bottom of the profile line positioning block 27 is slidably matched with the T-shaped slot. One side of the L profile line positioning block 27 is an arc side, and the arc side of the L profile line positioning block 27 is detachably connected with an L profile line pressing plate. 31. The arc-shaped side of the L-shaped line positioning block 27 and the L-shaped line pressing plate 31 are respectively clamped on both sides of the airway-shaped line segment 48 of the large blade 36.

[0040] In the present embodiment, the bottom of the L profile line positioning block 27 is slidably matched with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com