Feeding type cylinder side edge strip wing drilling fixture

A technology of drilling fixtures and side strips, which is applied in the direction of drilling/drilling equipment, manufacturing tools, and drilling molds for workpieces, etc., which can solve the problems of inability to process, long time consumption, and long processing cycle, etc., to achieve Ensure the assembly requirements, improve work efficiency, and improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

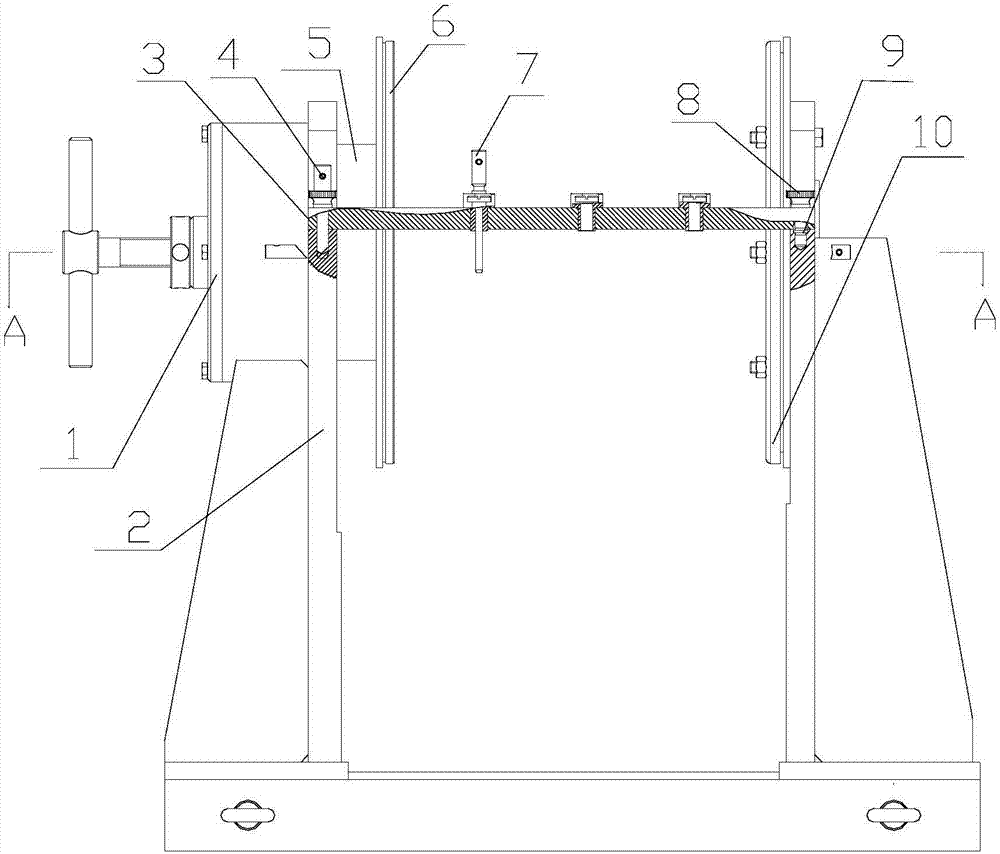

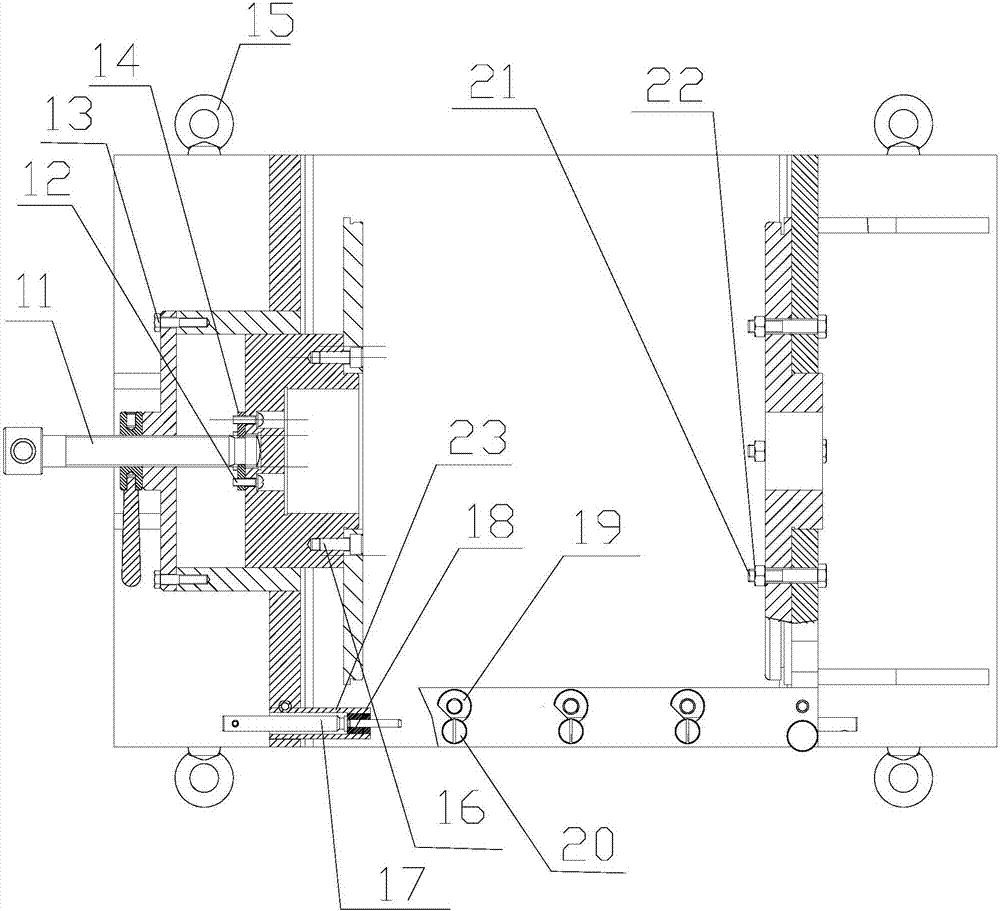

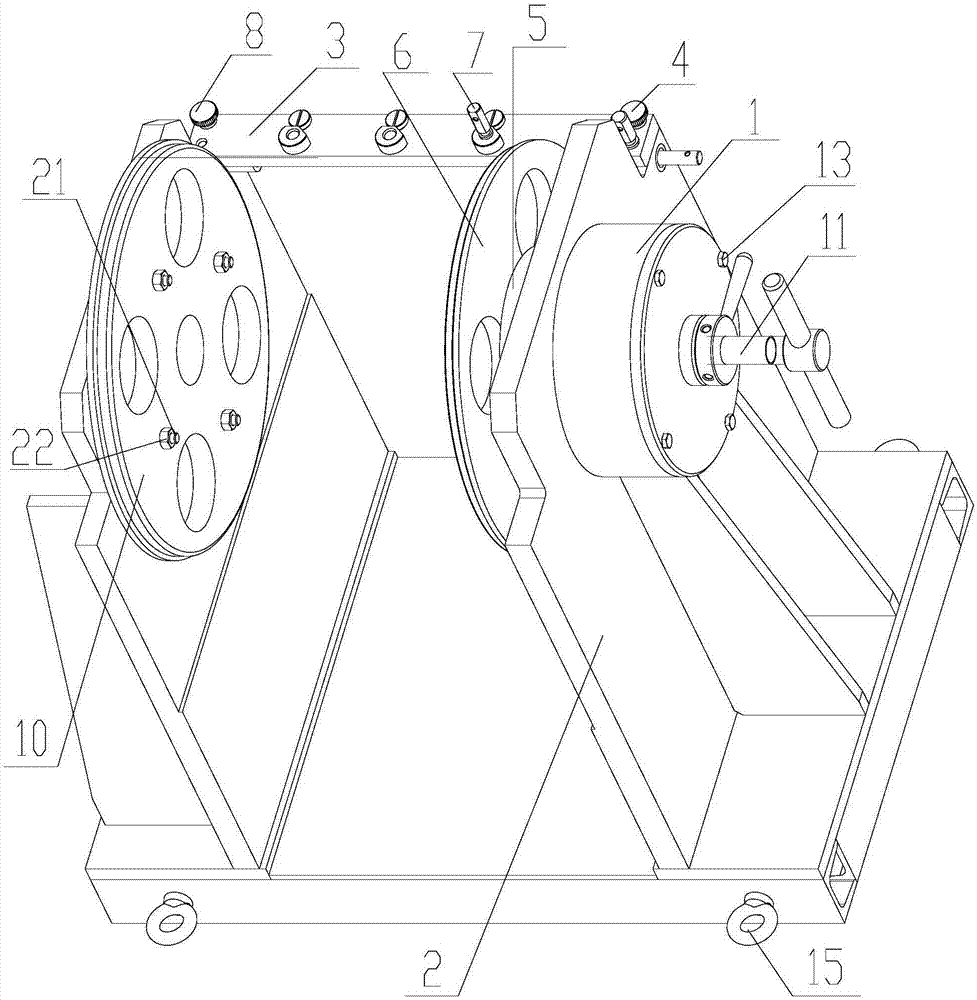

[0022] A kind of feed type cylinder side strip wing drilling jig, see Figure 1-7 , including clamp body 2, drill template 3, rotating shaft 5, adjustable positioning plate 6, blocking cover 1, pressure plate 10, limit block 14, compression screw 11, knurled high-head screw 8, positioning pin a4, positioning pin b7, quick change drill sleeve 19, bolt washer assembly 12 and other parts, specifically:

[0023] The clamp body 2 is welded by steel plate 1-1, left support 1-2, right support 1-3, and base 1-4, and the base 1-4 is welded by channel steel, and the overall aging after welding is as required Processed in place, four lifting ring screws 15 are installed on both sides of the base 1-4 of the clamp body 2, which are used for lifting the whole feed type cylinder side strip wing drilling jig, the clamp body 2 is the main body of the present invention, and all the other parts are installed on the clamp body 2 to form a whole;

[0024] The blocking cover 1 is connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com