Special angular contact ball bearing for liquid vortex flow retarder

An angular contact ball bearing and retarder technology, applied in ball bearings, bearing components, shafts and bearings, etc., can solve problems such as unbearable, large axial load, failure, etc., to ensure rotation, increase friction, optimize shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

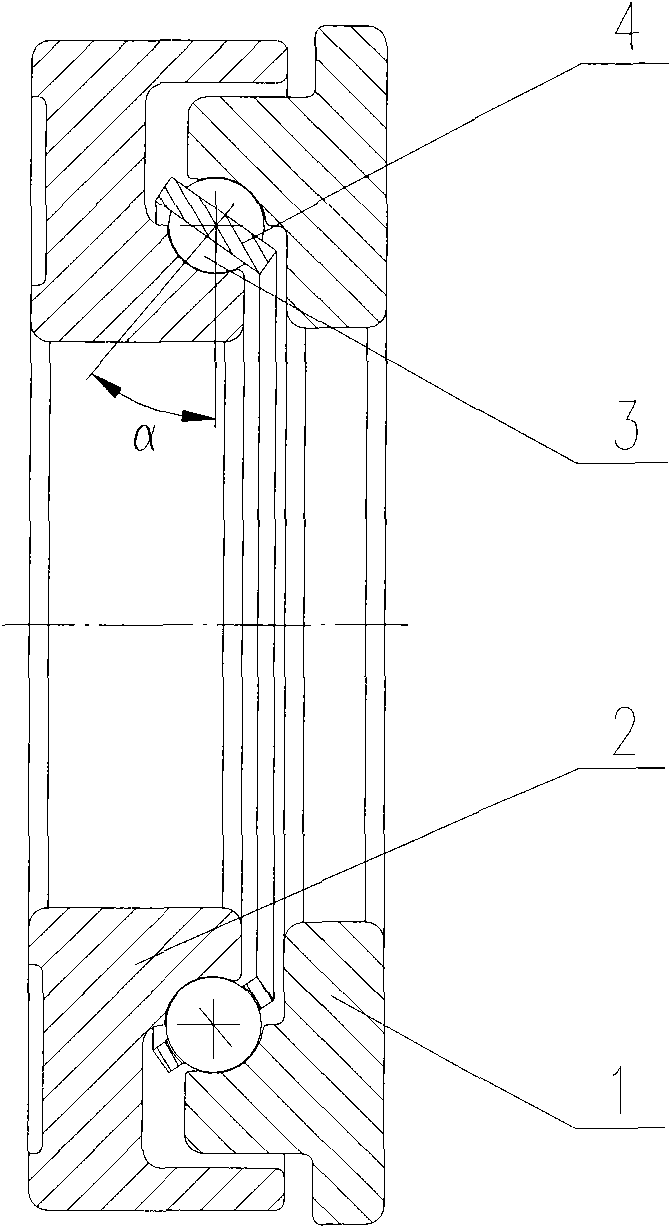

[0012] Specific embodiments of the present invention are described with reference to the accompanying drawings.

[0013] as attached figure 1 Shown: the parts of bearing of the present invention include: outer ring 1, inner ring 2, steel ball 3 and cage 4.

[0014] The contact angle α of the bearing is designed to be 40°, which is designed to enable the bearing to carry both radial load and large axial load at the same time.

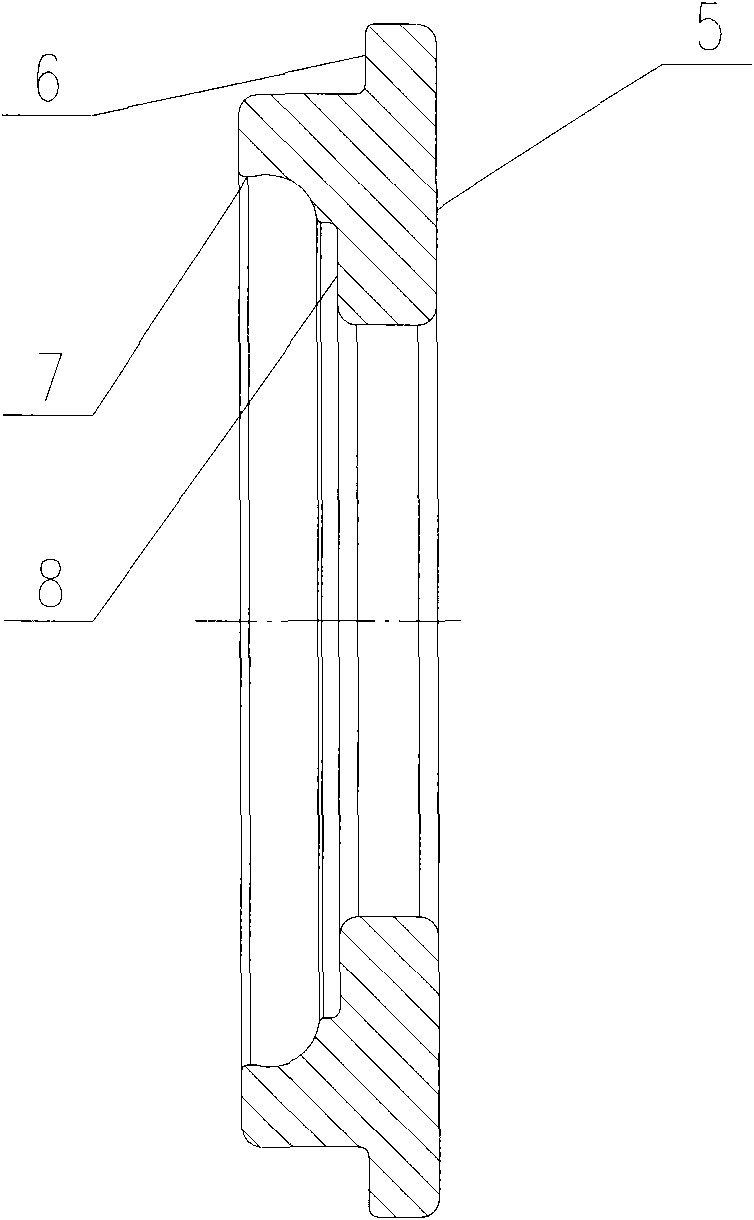

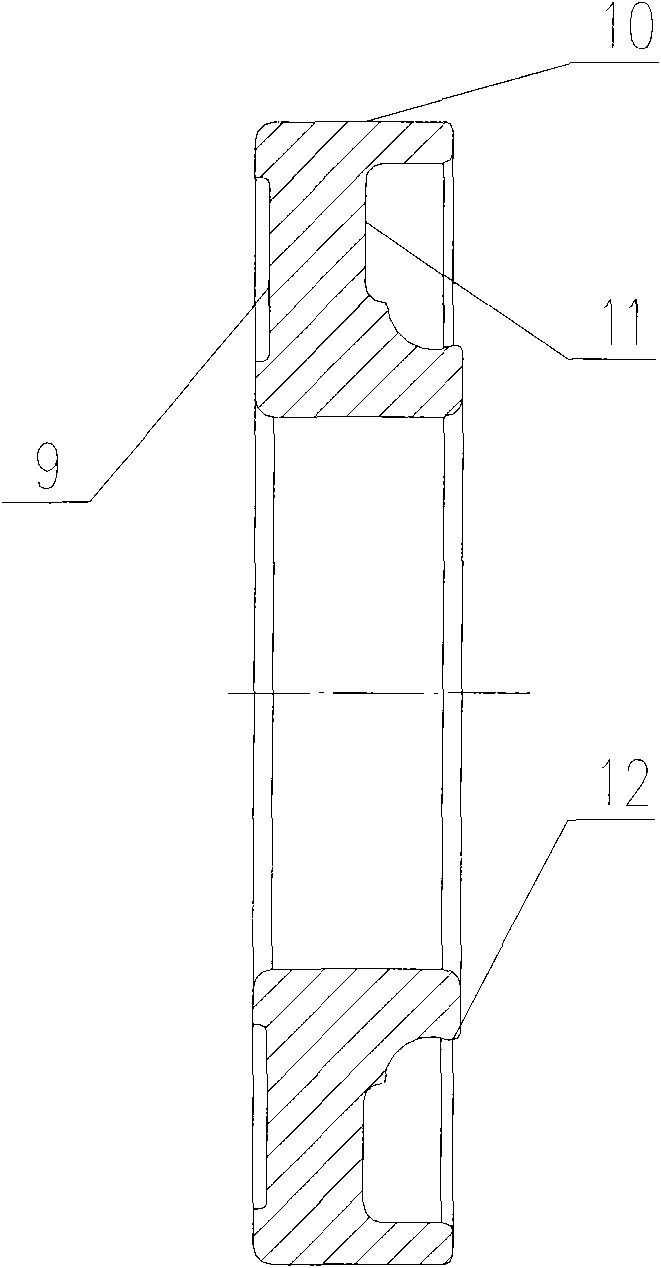

[0015] as attached figure 2 As shown: widen the large end face 5 of the outer ring 1 as much as possible to increase the friction between the end face 5 and the clutch plate; the design of the upper step 6 avoids interference with the protruding end of the outer diameter surface 10 of the inner ring 2; the lower step The design of 8 avoids interference with the small head of cage 4; the design of outer ring 1 raceway with locking point 7 not only ensures the assembly requirements of the bearing, but also solves the problem of loose sets of the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com