Double-layer composite plastic floor

A plastic floor, double-layer composite technology, applied in the field of plastic floor, can solve problems such as poor structural strength, increase manufacturing precision, manufacturing cost, and difficulty in meeting assembly requirements, and achieve the goal of reducing manufacturing process difficulty, prolonging service life, and reducing stress concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

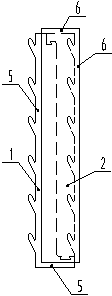

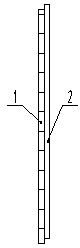

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, it is a preferred embodiment of the double-layer composite plastic floor of the present invention, including the floor surface layer 2 and the floor cushion layer 1 placed thereunder, and the surface shapes of the floor surface layer 2 and the floor cushion layer 1 are rectangular , the two are parallel to each other, horizontally and vertically dislocated and glued together, and the protruding parts form the connecting strip 5 and the connecting strip 6, and different connecting surfaces are coated on the connecting strip 5 and / or the connecting strip 6. dry glue.

[0025] Such as figure 1 , Figure 5 , Figure 6 , Figure 7 As shown, the floor cushion 1 is formed in this way: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com