Double-layered composite plastic floorboard with tongue-and-groove connection structure

A connection structure, double-layer composite technology, applied in the field of plastic floors, can solve the problems affecting the service life of plastic floors, the trouble of floor assembly, disassembly and assembly, and the increase of manufacturing costs, so as to achieve fast plug-in connection, improve structural strength, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

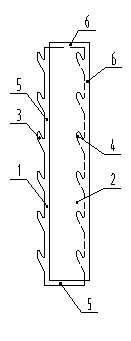

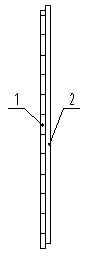

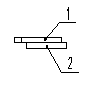

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , shown in Fig. 9, is a preferred embodiment of the socket connection structure double-layer composite plastic floor of the present invention, comprises floor surface layer 2 and the floor cushion layer 1 that places under it, floor surface layer 2, floor cushion layer 1 The surface shape is rectangular, and the floor cushion 1 is formed in this way: on the long sides on both sides of the floor cushion 1, the outer convex tongue 3 and the inner concave tongue and groove 4, which can form a plug-in connection, are respectively cut out. 3. The shape of the tongue and groove 4 is a parallelogram, and one side of the parallelogram line coincides with the long sides on both sides of the floor cushion 1; the tongue 3 has an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com