Wedging type double-layer composite plastic floor and floor laid by utilizing wedging type double-layer composite plastic floor

A plastic floor, double-layer composite technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems that affect the service life of plastic floors, floor assembly, disassembly, poor structural strength, etc., and achieve manufacturing accuracy and easy control , Improve the structural strength, easy to measure the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be further explained based on the drawings and the embodiments.

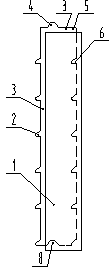

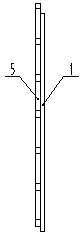

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 In the shown wedge-type double-layer composite plastic floor, the surface of the floor surface 1, the floor cushion 5 is rectangular, and several connecting tenons that can form a wedge connection are cut out at equal intervals on both sides of the long side of the floor cushion 5 2. The shape of the connecting notch 6, cut out a connecting tenon 4 and a connecting notch 8 that can form a wedge connection on each side of the short side of the floor cushion 5. The connecting tenon 2 and the connecting tenon 4 are wedge-shaped The connecting notch 6 and the connecting notch 8 are wedge-shaped grooves, and the ends of the connecting tenon 2 and the connecting tenon 4 are provided with rounded corners. The rounded corners here are mainly used for guiding the subsequent floor assembly; in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com