A precision machining method and detection device for a flame stabilizer

A flame stabilizer and precision machining technology, which is applied in the field of mechanical processing, can solve the problems of low pass rate of precision ear seat hole processing, large deformation of parts, etc., meet product technical requirements and assembly requirements, good consistency, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

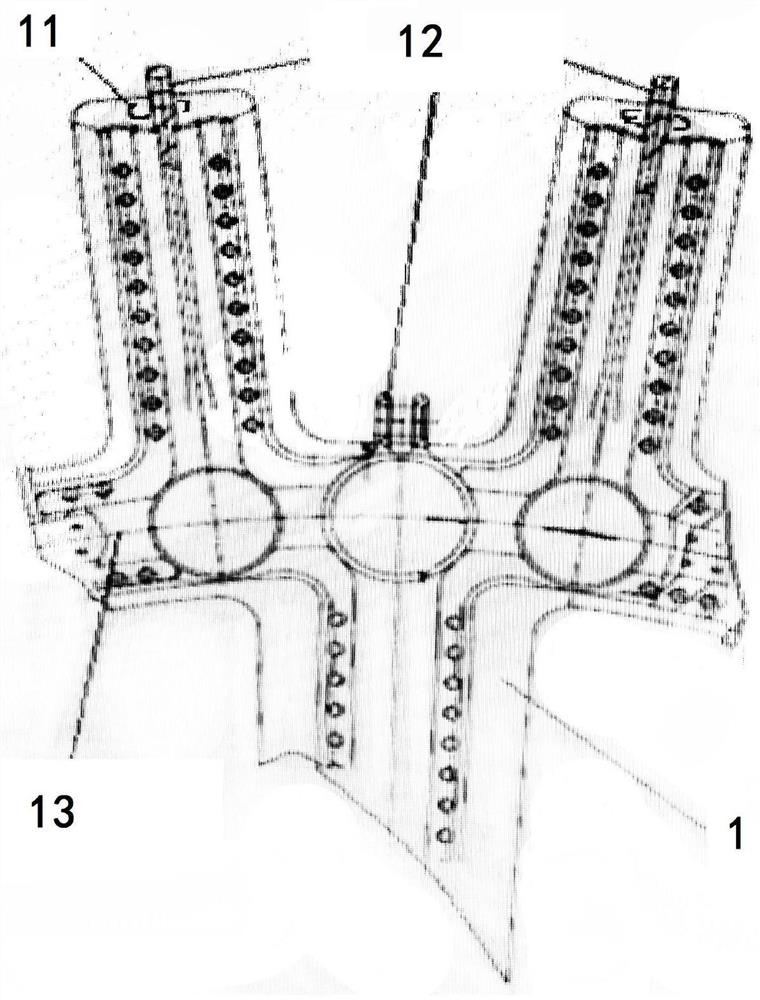

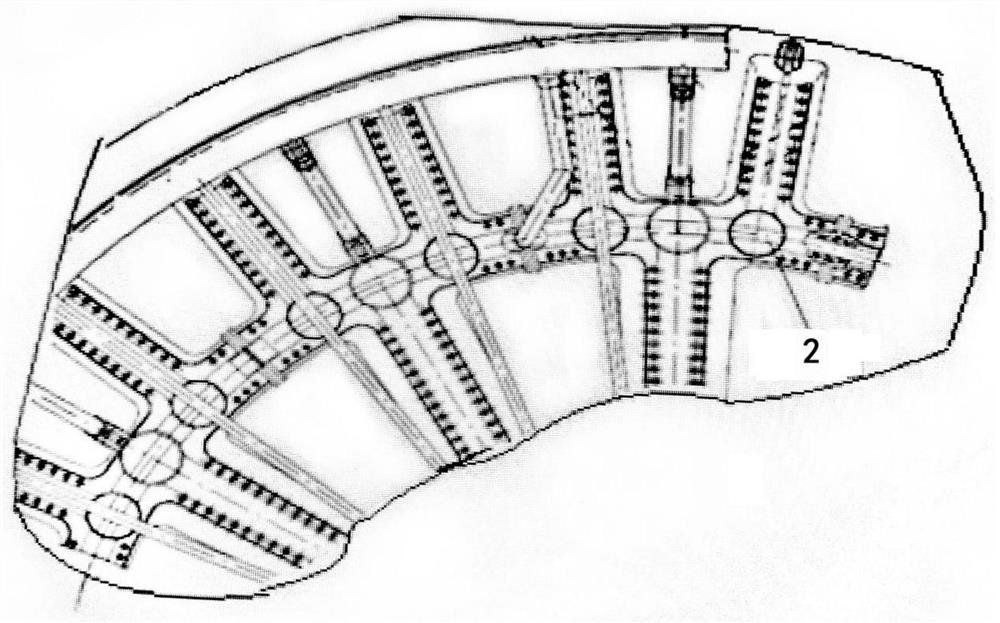

[0026] Such as Figure 1-2 As shown, a precision machining method for a flame stabilizer includes the following steps:

[0027] Step 1, argon arc welding precision casting and plug 11;

[0028] Step 2, milling the ear seat, removing the ear seat allowance, and ensuring the wall thickness and position of the ear seat;

[0029] Step 3, drilling and processing the ear seat hole 12 to ensure the position of the ear seat hole 12;

[0030] Step 4, spraying a high temperature resistant coating on the surface of the part;

[0031] Step 5, reaming, remove the 12 margins of the ear seat hole, and ensure the precise ear seat hole size;

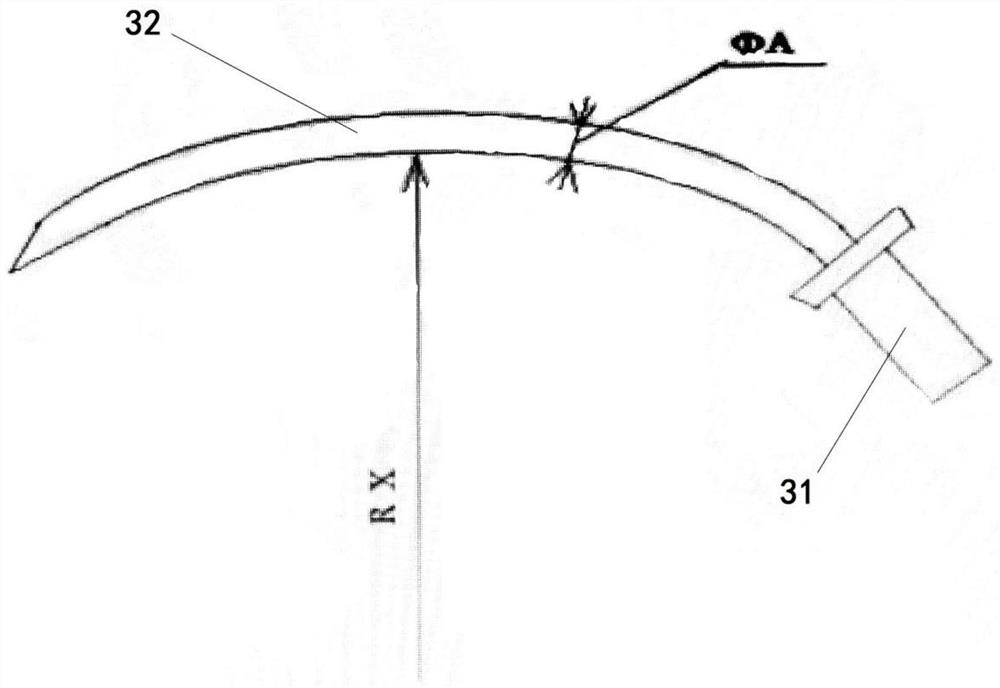

[0032] Step 6, according to the diameter and arc radius of the oil delivery pipe 2 and the arc length of the annular channel of the stabilizer, a detection device is manufactured, and the detection device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com