Lead bending die of rotor winding and processing method

A rotor coil and processing method technology, applied in the field of hydroelectric generators, can solve the problems of high processing and manufacturing precision and mold manufacturing costs, increased man-hours and energy consumption, long debugging time, etc., and achieve high bending quality of coil leads and structural Simple, low-cost-to-produce effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

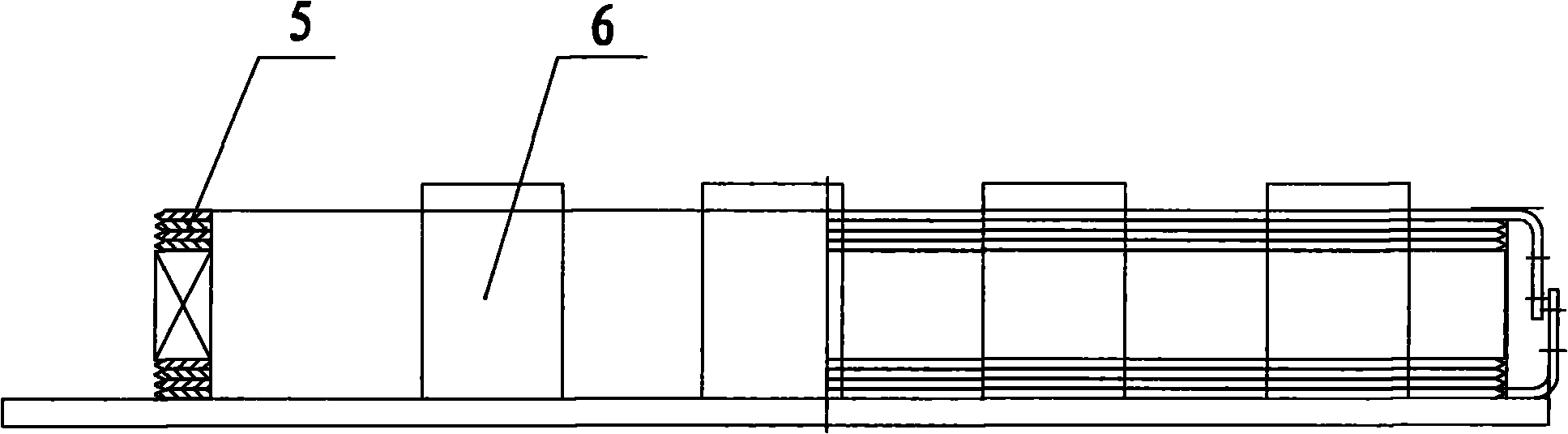

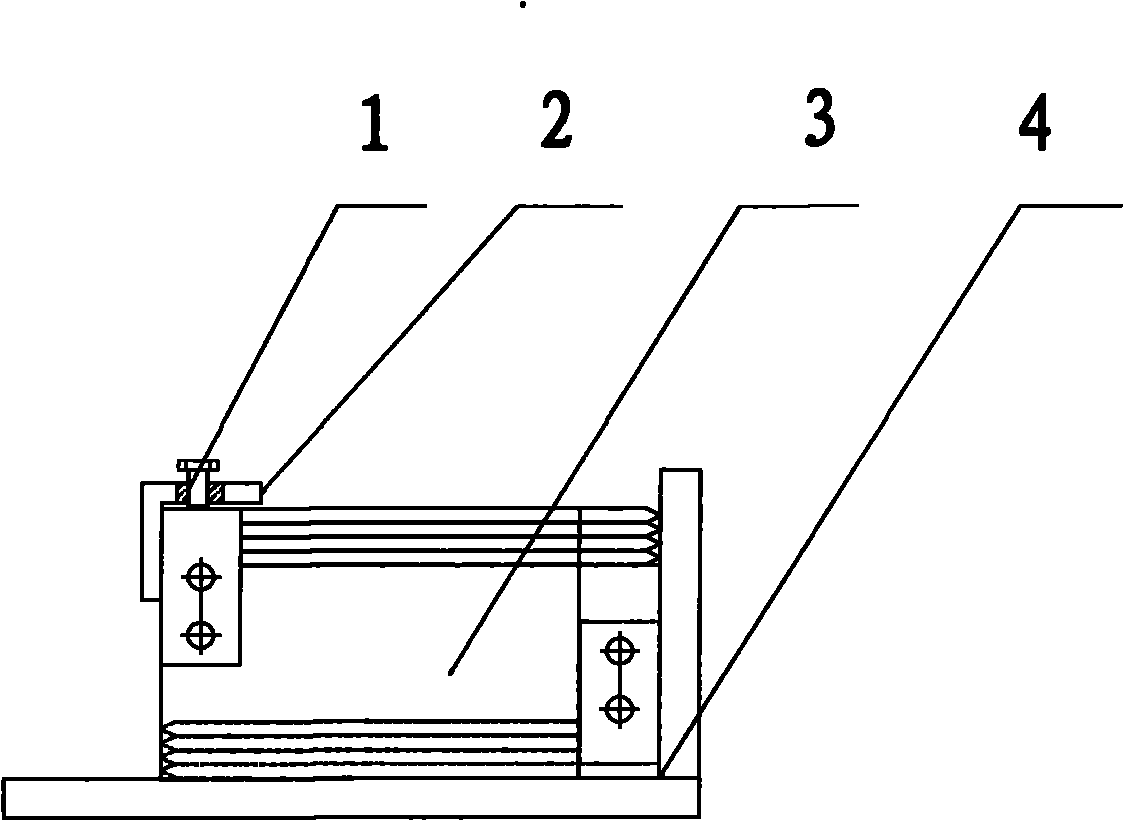

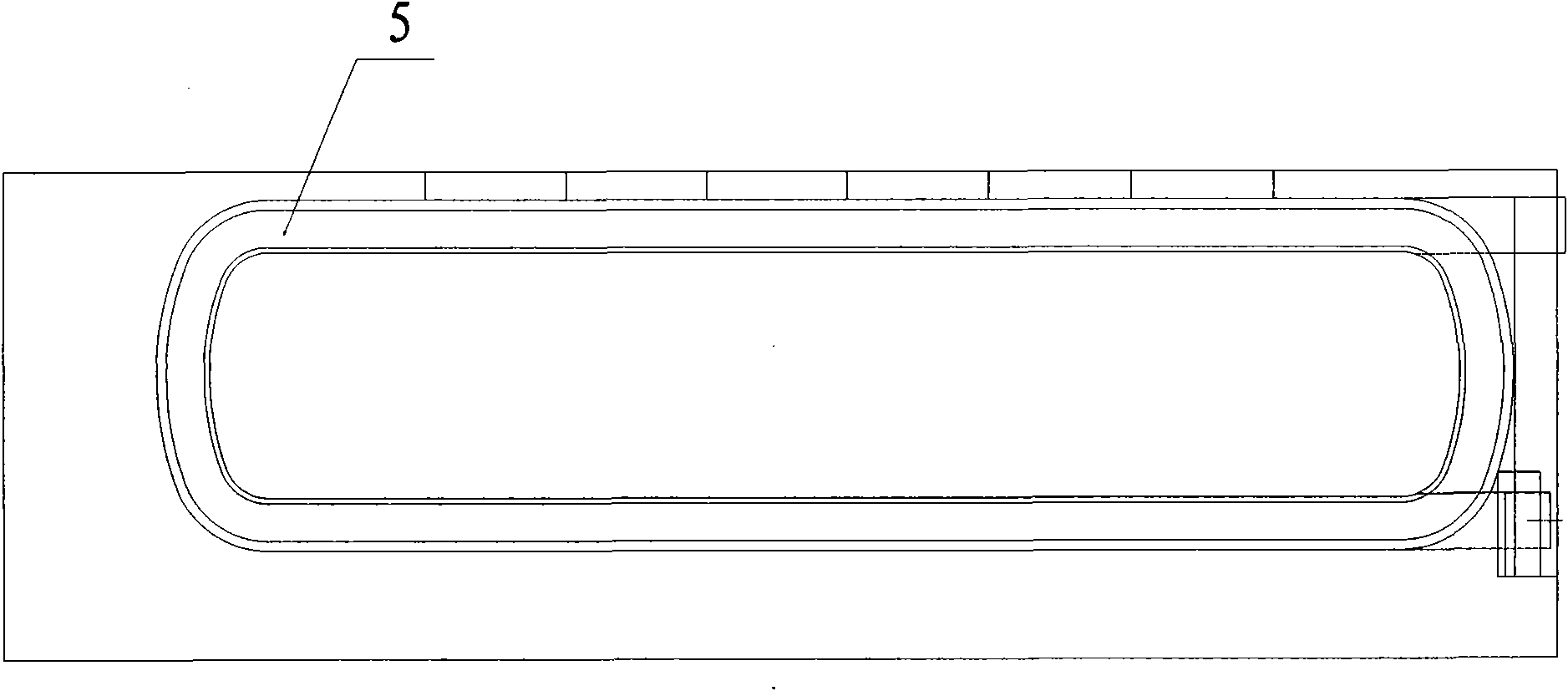

[0029] A rotor coil lead wire bending die, including a base plate 4, a wire pressing plate 2, a positioning plate 3, a support plate 6, a compression bolt 1, etc., the base plate and the support plate are vertically welded together so that the length direction of the rotor coil 5 is close to each other Accurate positioning on the support plate. The width dimension of the positioning plate is processed according to the length of the lead wire in the design drawing, and a notch is opened at the bending position of the right lead wire at the bottom. The position size is designed on the positioning plate, and the side plate is connected with the positioning plate, and then the positioning plate is placed on the bottom plate and welded firmly. Weld the crimping plate to the left side of the positioning plate. On the bending tooling, the positioning plate is used for positioning and bending the ends of the rotor coils to ensure consistent bending positions of the lead wires. A cla...

Embodiment 2

[0031] A rotor coil lead wire bending processing method, using the bending die in Embodiment 1 for processing, the rotor coil lead wire bending processing process includes annealing of the rotor coil through copper bars, flat winding, secondary annealing of the rotor coil, cold pressing, After the lead wire is marked, tinned and drilled, the rotor coil lead wire is bent. The lead wire bending process is to place the rotor coil on the bending die, and position the end of the rotor coil against the positioning plate. The lead wires of the copper bars are clamped by the compression bolts through the crimping plate, and the operator uses an iron hammer to beat the lead wires according to the shape, and the lead wires are simmered and bent.

[0032] Concrete operation process of the present invention:

[0033] 1. First process and assemble according to the design drawing of the rotor coil bending tooling. 2. Mark the lead wire, level the lead wire, mark the lead wire, enamel tin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com