Method and apparatus for obtaining cavities on surfaces of ceramic items

A technology for ceramics and products, used in ceramic molding machines, metal processing equipment, grinding/polishing equipment, etc., which can solve problems such as long time, inaccuracy, and rapid wear of milling cutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

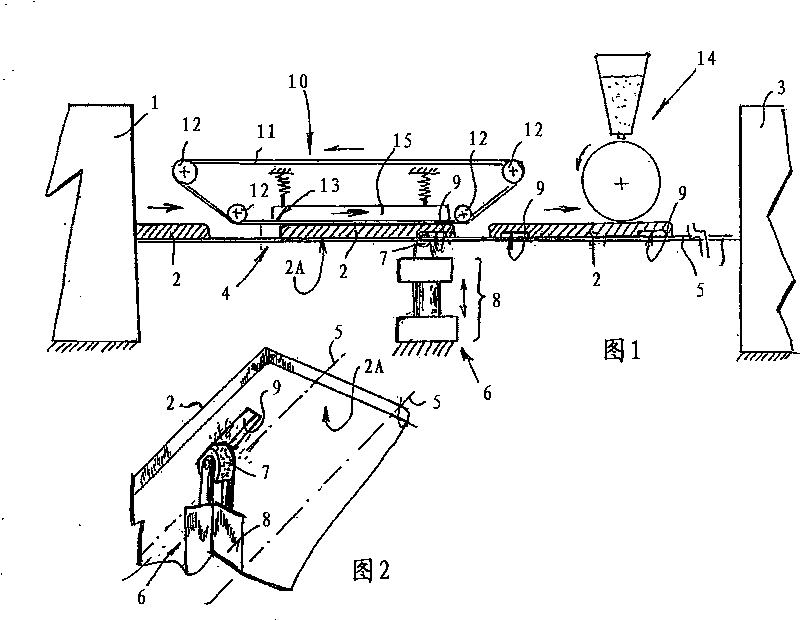

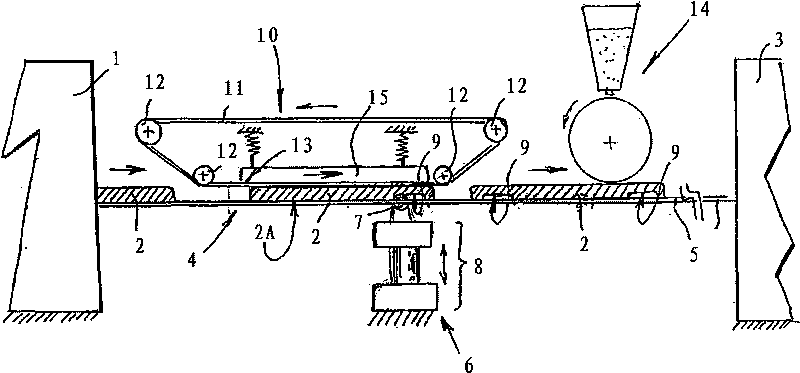

[0024] According to the drawings, numeral 1 denotes a drying device for ceramic products such as tiles 2 , and numeral 3 denotes a kiln for firing tiles 2 .

[0025] A conveyor line 4 , usually with parallel belts 5 , is arranged between the drying unit 1 and the kiln 3 , while the tiles 2 located thereon are transported from the drying unit to the kiln 3 for firing for final stabilization.

[0026] The conveying line 4 comprises a removal device 6 mounted below the parallel belt 5 and having a grinding wheel 7 mounted on a lifting or lowering unit generally indicated by the numeral 8, between a working position and a stop position for removing ceramic material between movement.

[0027] An enamel covering device or decoration device can also be installed between the drying device 1 and the kiln 3 , downstream of the removal device 6 , which is schematically indicated by numeral 14 .

[0028] The wheels 6A of the removal device 6, or other components known to those skilled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com