Patents

Literature

35results about How to "Efficient processing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable color thermoprinting membrane and making method thereof

ActiveCN103921582AIncrease contrastImprove visual recognitionDuplicating/marking methodsMetal layered productsMicro nanoHot stamping

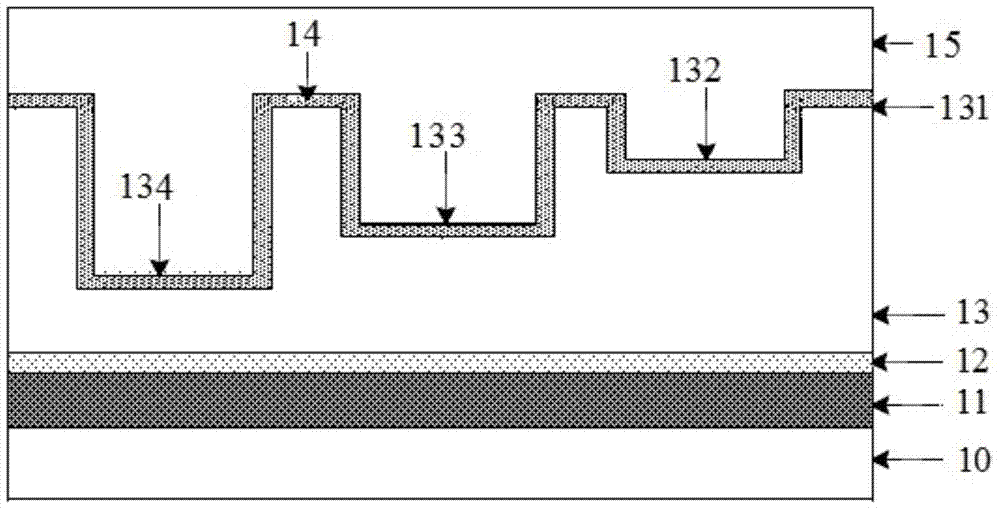

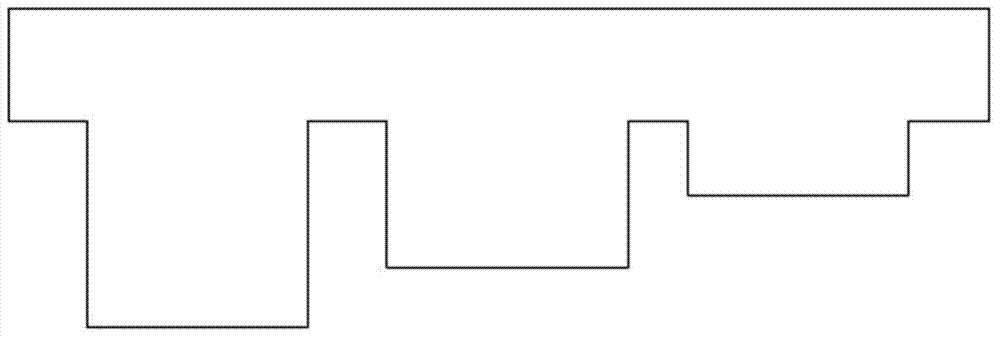

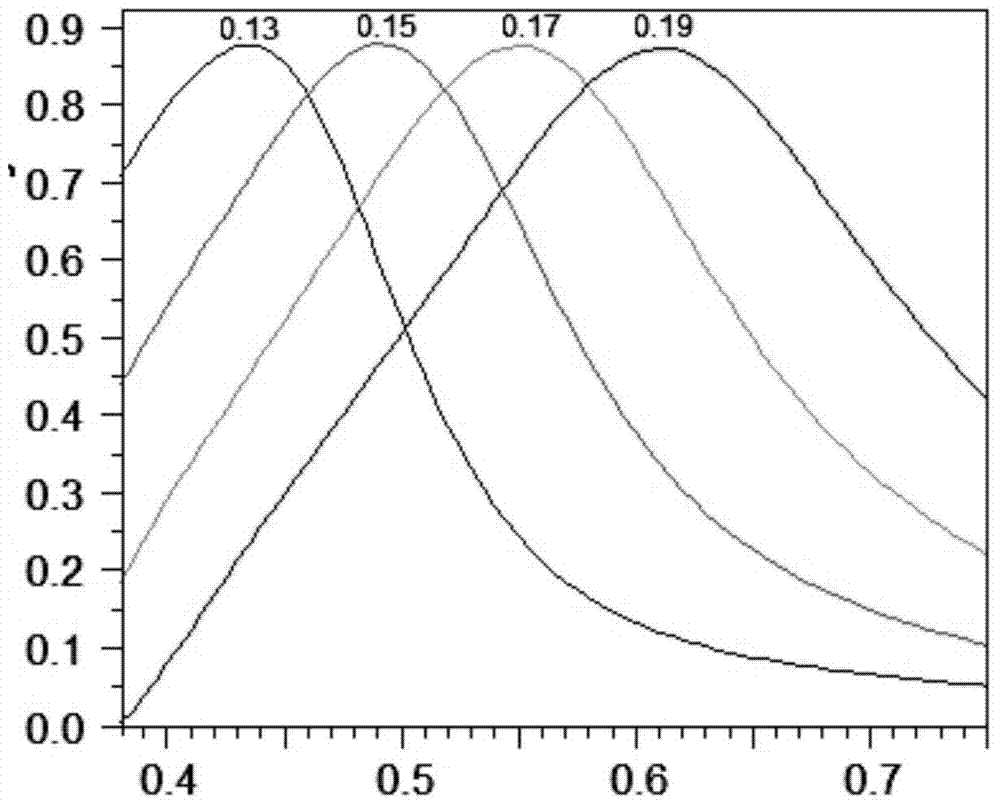

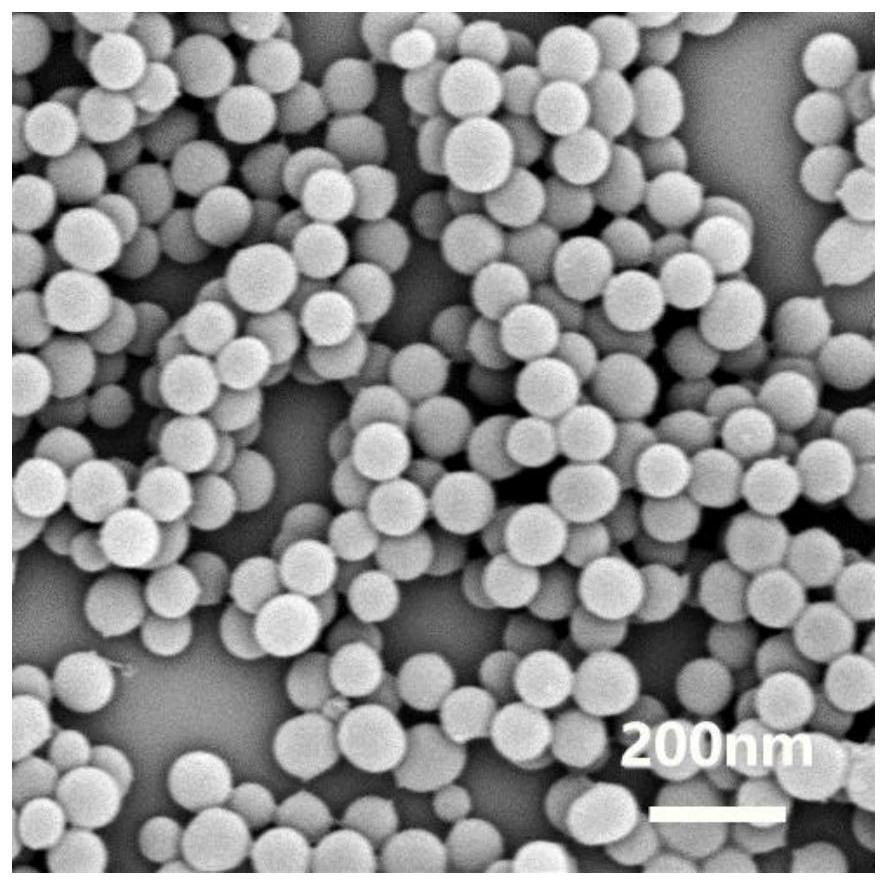

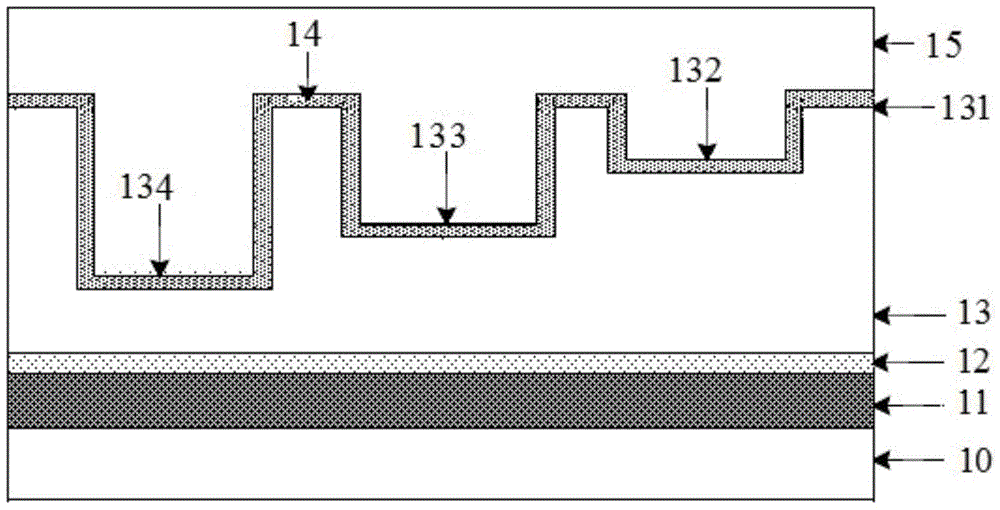

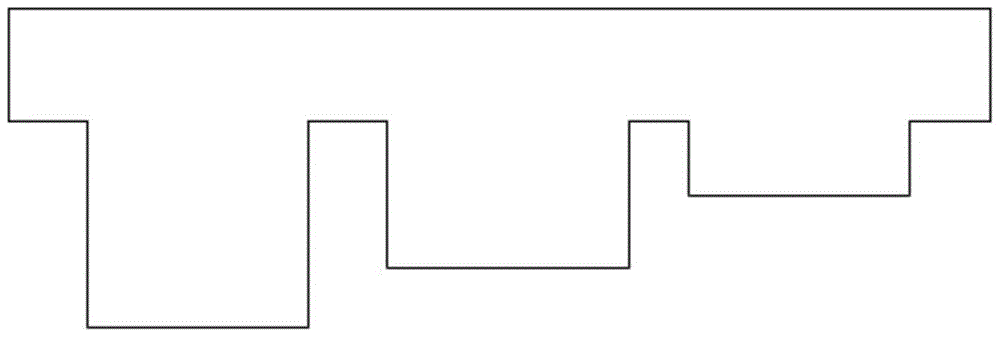

The invention relates to a variable color thermoprinting membrane and a making method thereof. The variable color thermoprinting membrane includes a base membrane, a release layer, a transflective metal layer, an information medium layer, a total reflecting metal layer and a hot melt adhesive layer, the information medium layer is a yieldable organic medium coating, steps with different heights are arranged on the at least one surface of the information medium layer or in the information medium layer, and the height of each of the steps corresponds to the Fabri-Perot cavity of a color. The above Fabri-Perot cavities enable a plurality of variable color zones, variable color figures and characters to be formed on a same hot stamping membrane, can realize the change of the color effect with the viewing angle under different polarization, and the color of the novel thermoprinting membrane changes. The thermoprinting membrane is made in a roll-to-roll manner, a heat evaporation coating partially substitutes a vacuum sputter coating, the organic medium coating is made in an efficient nano-coating manner, and steps and a micro-nano structure are obtained through an impression means, and the method is simple and efficient, and is suitable for wide format production.

Owner:SUZHOU UNIV +1

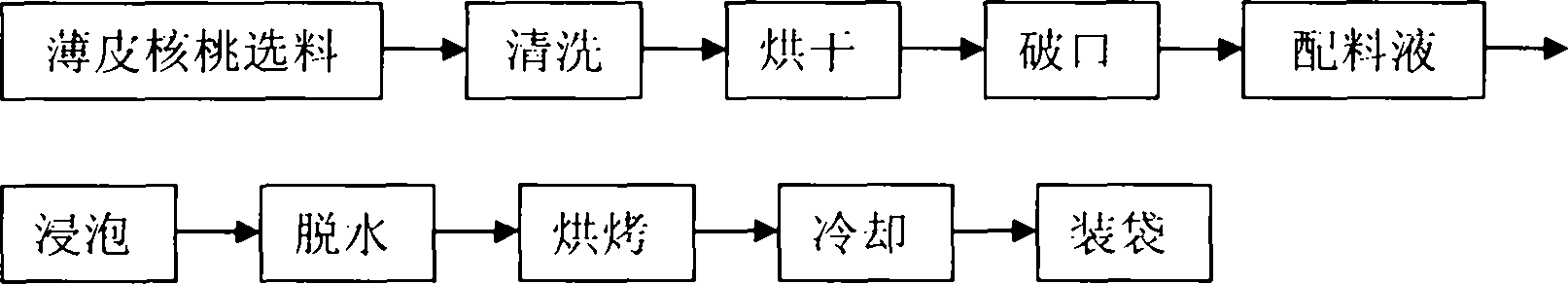

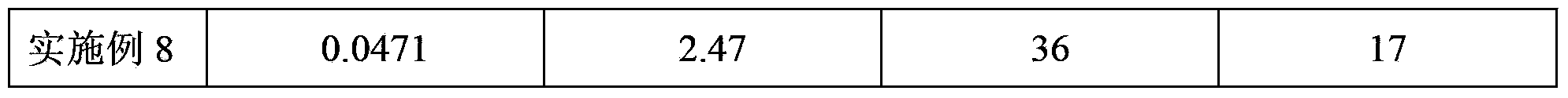

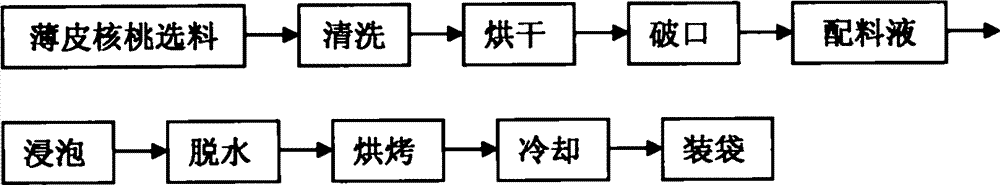

Processing method for multi-flavor thin-skin walnut and walnut prepared by same

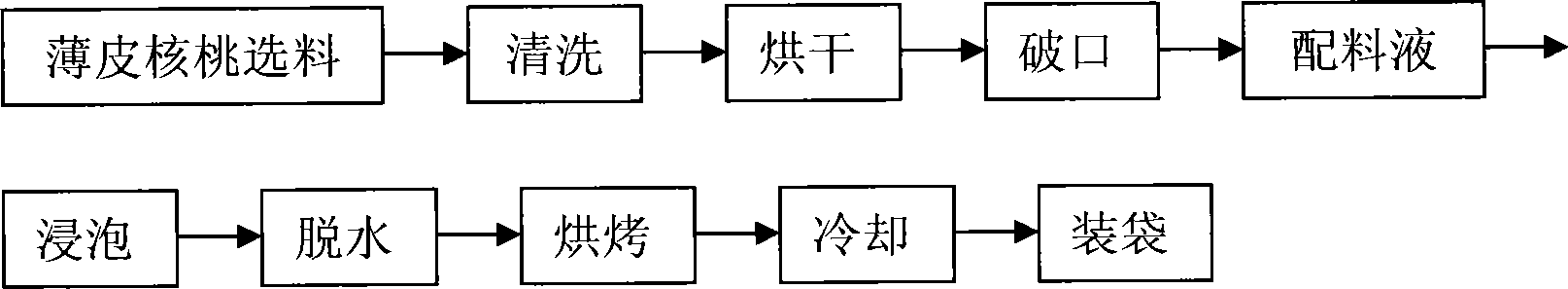

The invention relates to the technical field of production and processing of walnut products, in particular to a processing method for a multi-flavor thin-skin walnut and the walnut processed by the processing method. The processing method comprises the following process steps of: selecting a thin-skin walnut; cleaning, drying and cracking; preparing a liquid; soaking the walnut in a seasoning liquid at high pressure for 24 hours; removing a residual liquid in the walnut by using a food dryer; placing the walnut into an electro-thermostatic blast oven for roasting; controlling the temperatureto be about 100DEG C for 2 hours; cooling the roasted walnut; and bagging, vacuumizing and sealing. According to the processing method disclosed by the invention, a traditional production process of easily-cracked nuts is improved from the selecting and processing method; and the thin-skin walnuts from Sinkiang are selected and a high-pressure soaking technology is adopted, so that the process time is shortened and the quality of products is improved. The invention provides the simple and high-efficiency processing method with easiness in operation; peels of walnut products processed by the processing method are easily stripped; and the walnut products are convenience to eat, can be processed to obtain spiced and cream flavors and have fragrant and crisp mouthfeeling.

Owner:BEIJING UNIV OF AGRI

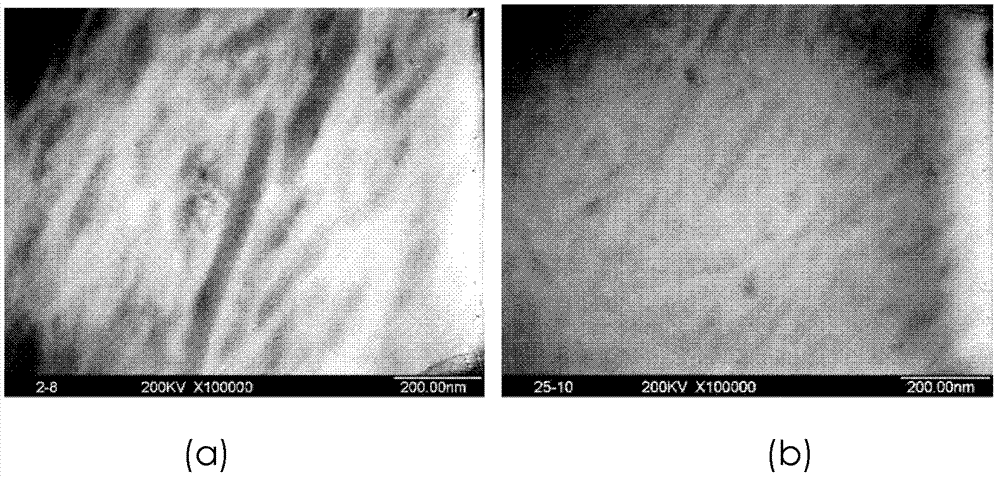

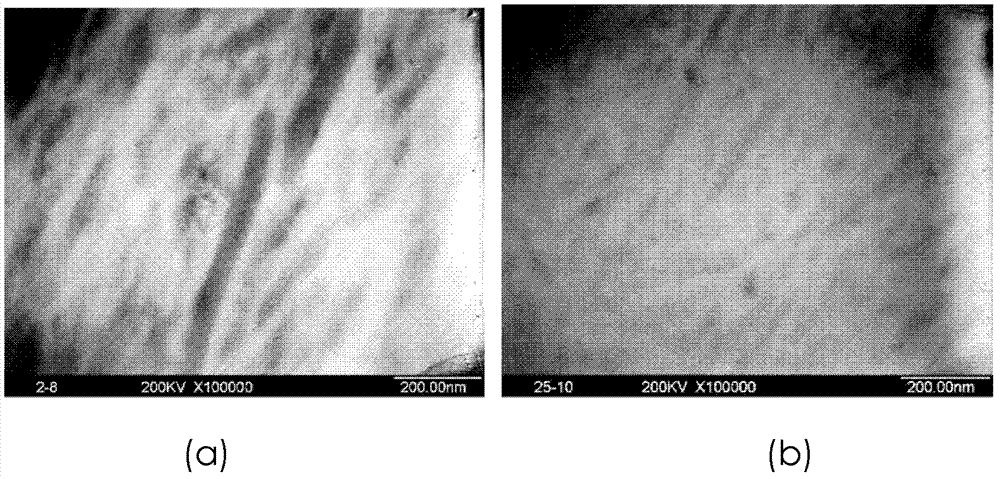

Preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber

InactiveCN103184586ALow priceWide variety of sourcesFibre chemical featuresCarbon fibersCellulose fiber

The invention relates to a preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber. According to the invention, a bacterial cellulose wet film is adopted as a substrate raw material. The prepared nano-grade carbon fiber is a product obtained after pyrolytic carbonization and graphitization of ultrafine bacterial cellulose fiber processed through an acupuncture carding refining treatment. The bacterial-cellulose-fiber-based nano-grade carbon fiber preparation method provided by the invention is safe, simple, and highly efficient, and has the advantages of wide raw material source, low price, and environment-friendly processing method. The bacterial-cellulose-fiber-based nano-grade carbon fiber obtained by processing has wide application field and great potential economic benefit.

Owner:ZHONGYUAN ENGINEERING COLLEGE

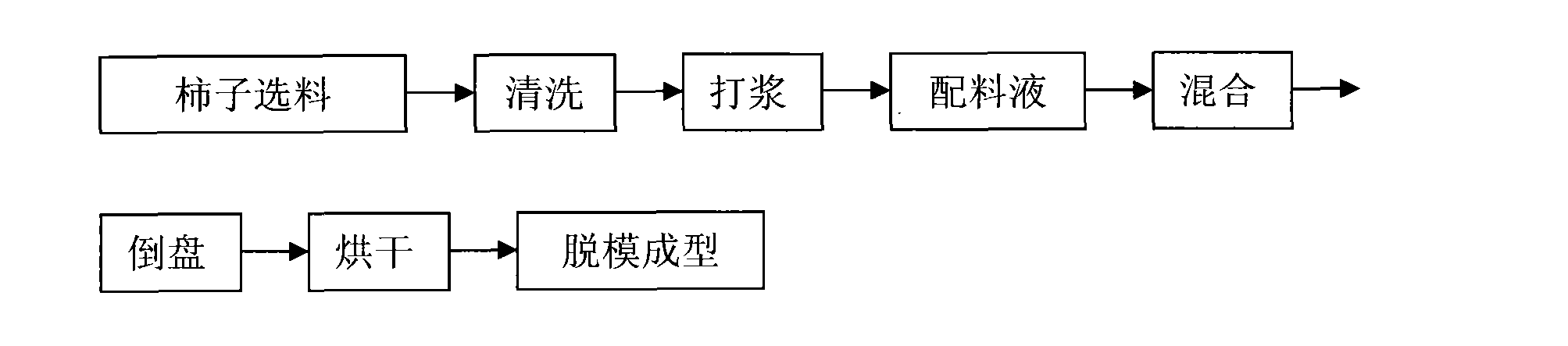

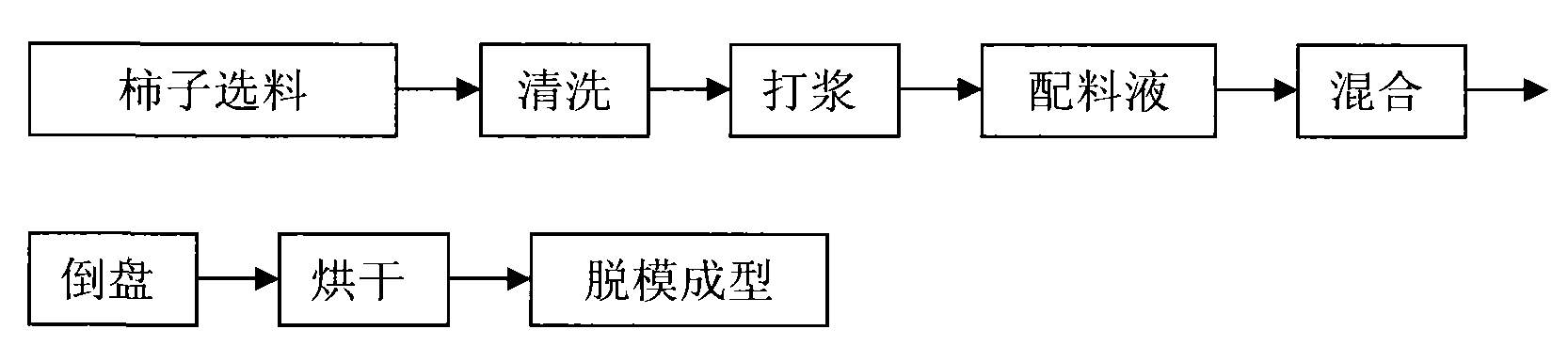

Method for processing persimmon cakes and persimmon cake prepared by using same

InactiveCN102349554ASimple processing methodEfficient processing methodBakery productsWater contentChemistry

The invention relates to the technical field of persimmon product production and processing and particularly relates to a method for processing persimmon cakes and a persimmon cake prepared by using the same. The method comprises the following steps: selecting persimmons; cleaning the selected persimmons with 5-15% salt water; pulping the cleaned persimmons; preparing a feed liquid; mixing the prepared feed liquid with the pulped persimmons; pouring the obtained product into a tray; putting the baking tray in an air drying cabinet to dry 8-10 hours, wherein the wind force is regulated to the maximum, and the temperature is controlled between 65 DEG C and 70 DEG C; and carrying out demoulding and forming on the obtained product. Compared with traditional persimmon product production processes, the method discloses by the invention has an improvement in the aspects of material selection (persimmons are all selected from Mopan persimmons, a famous excellent variety, produced in Fangshan District of Beijing) and processing method (a low-temperature forced air drying method is adopted), therefore, the processed persimmon cake can maintain the natural color of persimmons, and is appropriate in moisture content, high in resilience and sweet in taste.

Owner:BEIJING UNIV OF AGRI

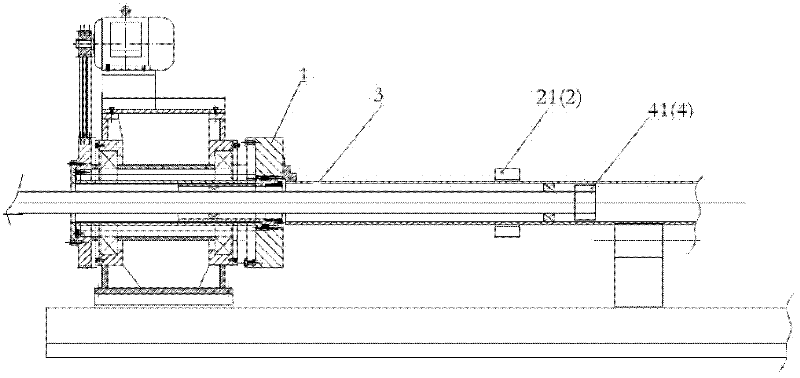

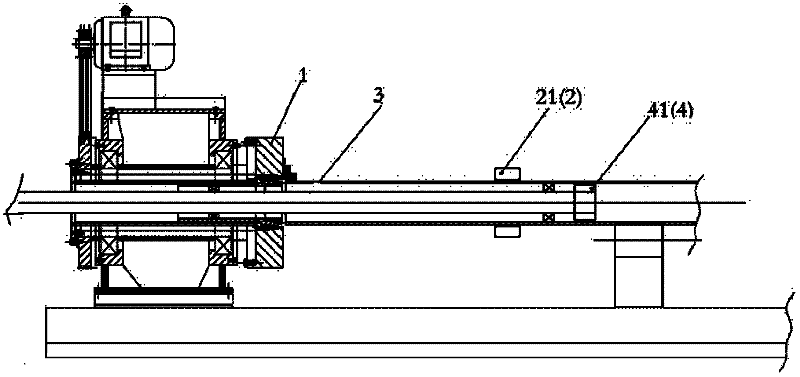

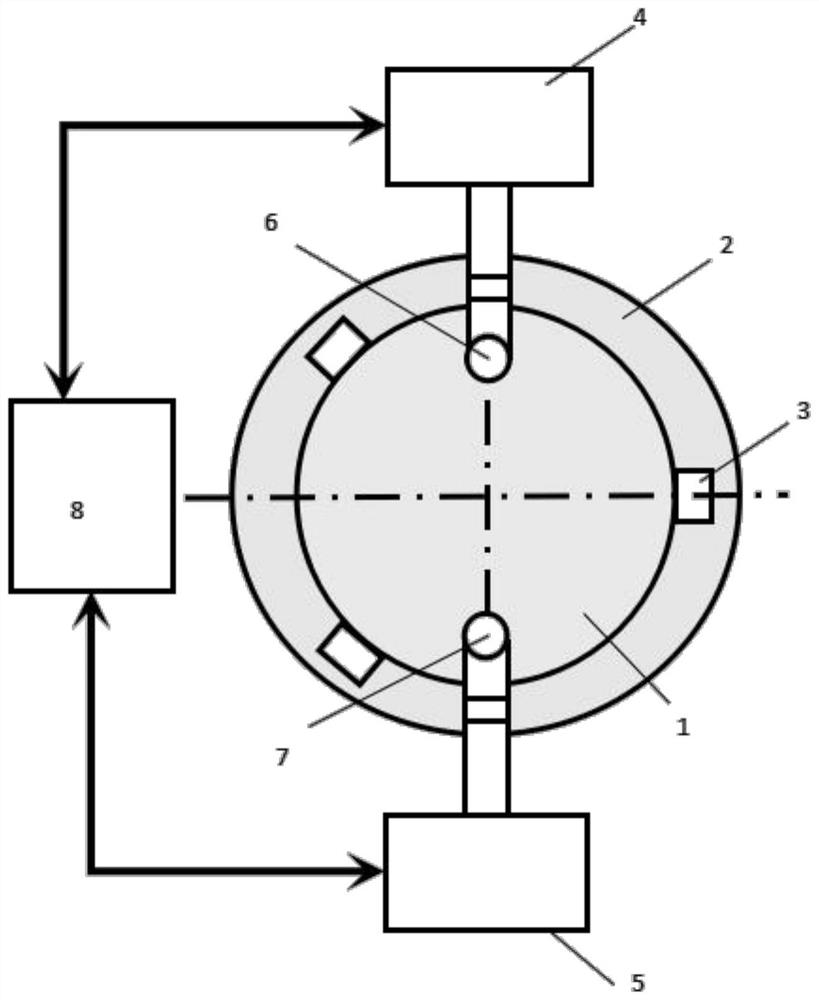

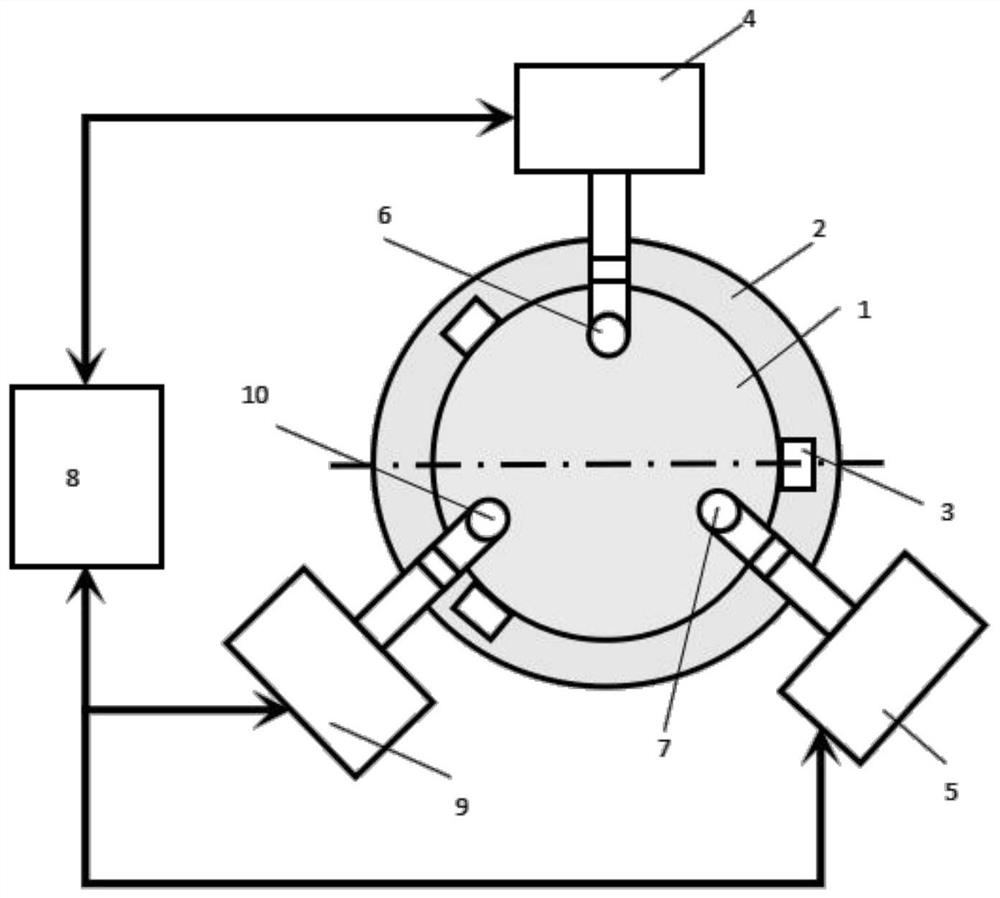

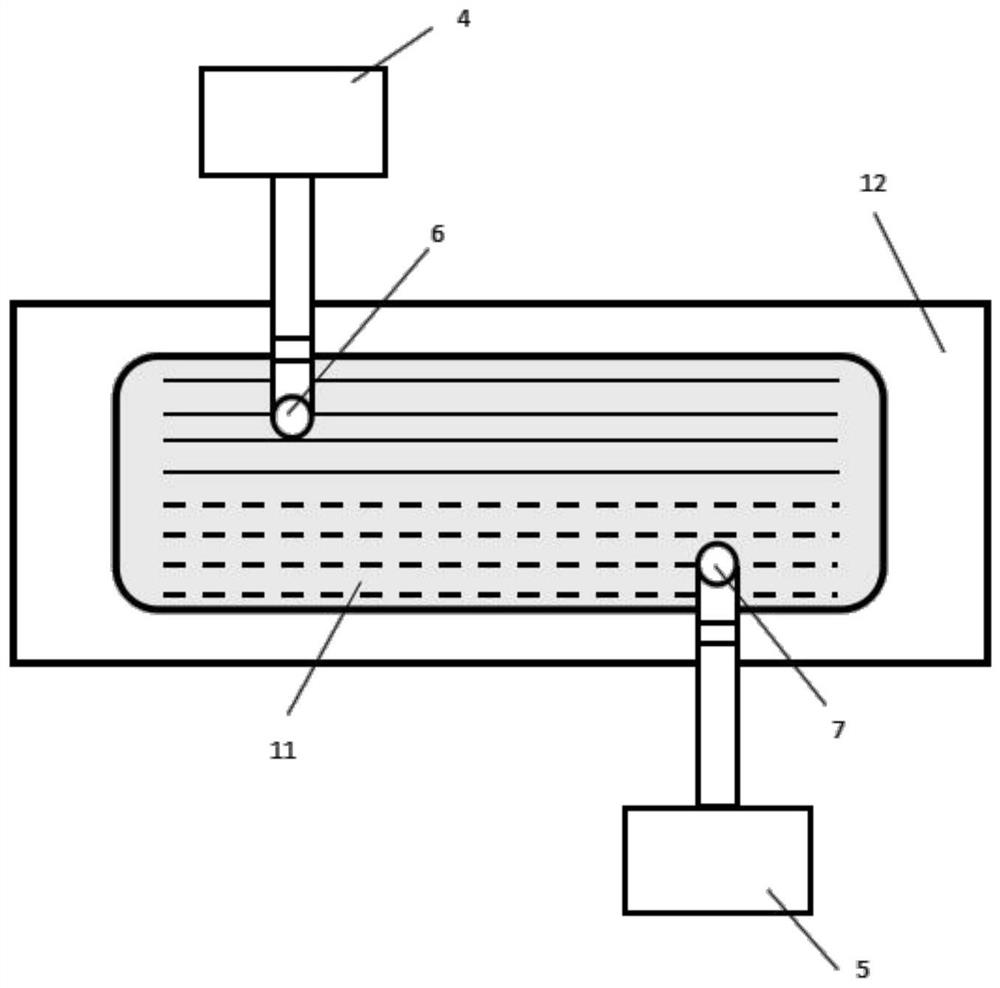

Steel tube as well as processing method and processing equipment for steel tube

ActiveCN102443691ATo achieve the purpose of wear resistanceEfficient processing methodIncreasing energy efficiencyFurnace typesWear resistantHardness

The invention discloses a processing method for a steel tube. The processing method comprises the following steps of: carrying out inner wall quenching on the steel tube to enable the steel tube to integrally form a martensite structure; carrying out medium-temperature tempering on the outer wall of the steel tube, which is processed by an inner wall quenching process, to enable the outer wall toform a tempered troostite structure; and meanwhile, carrying out low-temperature tempering on the inner wall to enable the inner wall and part of adjacent outer wall to form a tempered martensite structure. Therefore, the inner wall of the processed steel tube has higher hardness and wear resistant; the outer wall of the processed steel tube has higher toughness; and the processed steel tube can completely meet the requirements of wear resistance and toughness. The invention also discloses processing equipment for the steel tube. The processing equipment comprises a clamper for clamping the steel tube, an inner wall quenching device of a quenching sensor as well as an outer wall tempering device of a tempering sensor, wherein the inner wall quenching device can be moved inside the steel tube; and the outer wall tempering device can be moved on the outer wall of the steel tube. The processing equipment can be used for simultaneously finishing the inner wall quenching process and the outer wall tempering process and has high processing efficiency. The invention further provides the steel tube obtained by the processing method and the processing equipment disclosed by the invention.

Owner:ZOOMLION HEAVY IND CO LTD

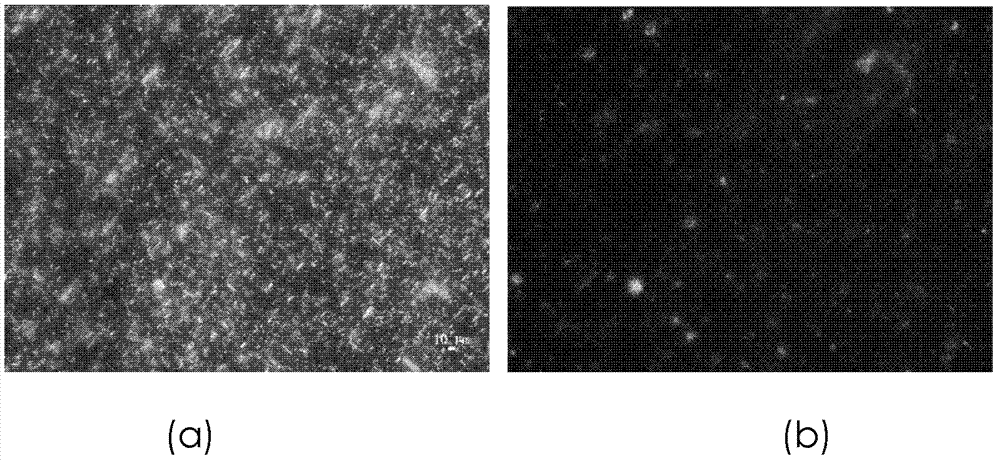

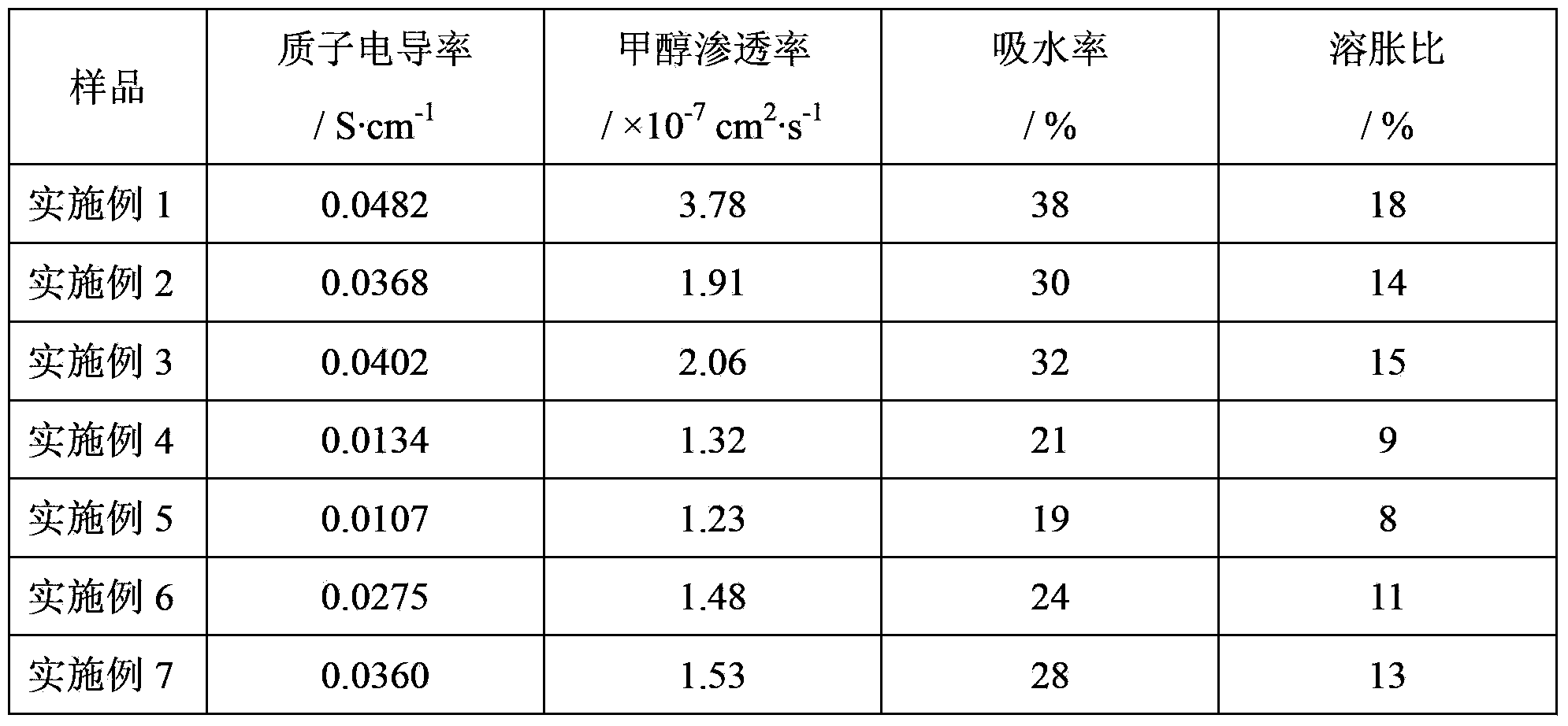

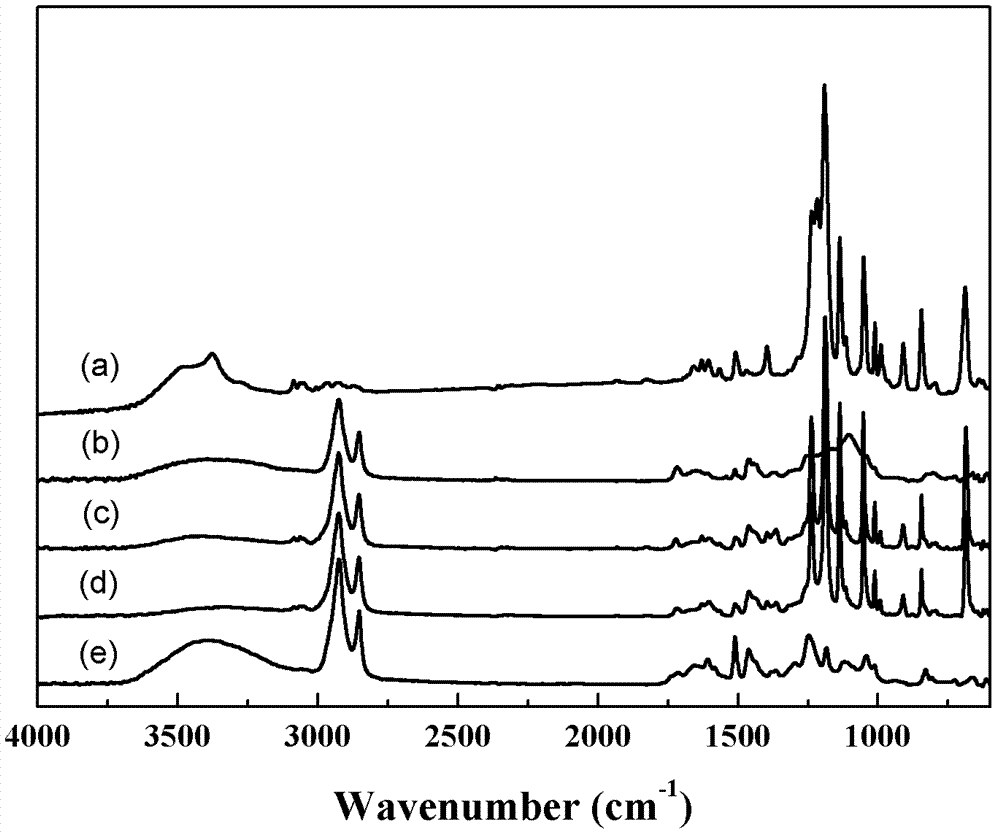

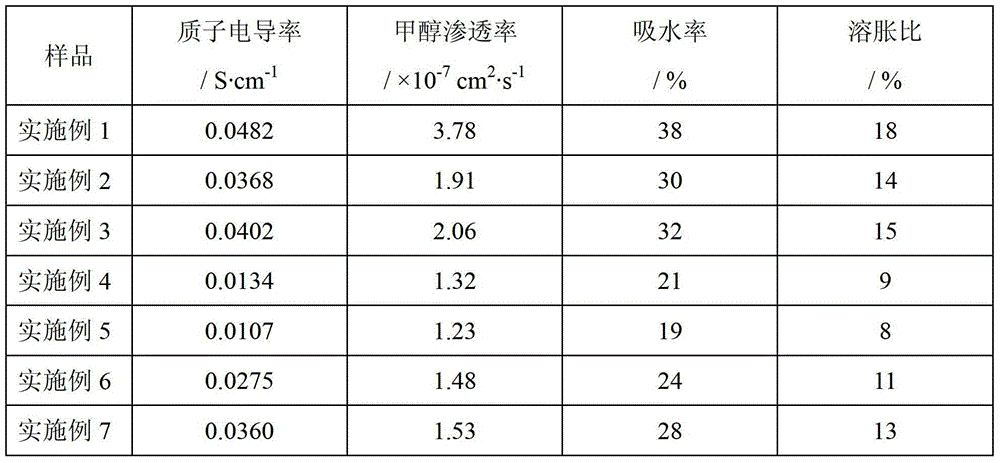

Preparation method of polymer matrix proton exchange membrane (PEM) with cross-linked structure

ActiveCN102775628AImprove performanceEffective graftingCell component detailsFuel cell detailsCross-linkPermeability coefficient

The invention relates to a preparation method of a polymer matrix proton exchange membrane (PEM) with a cross-linked structure, belonging to the field of battery electrolyte materials. The PEM is prepared by carrying out mechanical blending dispersion on matrix polymer material, unsaturated metal organic sulfonate, peroxide and auxiliary crosslinking agent, carrying out reaction in situ at the temperature of 140-200 DEG C, treating the product of the reaction by deionized water and sulfuric acid solution, and drying; and the PEM comprises the components in parts by weight: (1) 100 parts of matrix polymer material, (2) 20-150 parts of unsaturated metal organic sulfonate, (3) 1-20 parts of peroxide and (4) 0-5 parts of auxiliary crosslinking agent. In the molding process, organic solvent is not needed; and the preparation method is simple, high in efficiency, environment-friendly and low in cost. The prepared PEM has the proton conductivity approximate to Nafion (reaching up to the order of magnitude of 10<-2> / cm) and the methanol permeability coefficient far less than Nafion at the temperature of 20-80 DEG C, thus meeting the using requirement of a direct methanoi fuel cell.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of bacteria cellulose fiber-based carbon nanofiber knitted fabric

InactiveCN103184651AFine spatial networkHigh chemical purityWeft knittingCarbon fibresPolymer scienceCarbon fibers

The invention relates to a bacteria cellulose fiber-based carbon nanofiber knitted fabric, which is made through the following steps: adopting spinning and knitting technology to prepare a carbon nanofiber knitted fabric with a superfine bacteria cellulose fiber subjected to refining and carding treatment by the needling, and carrying out pyrolysis carbonization and graphitization. The preparation method has the benefits that the raw material source is wide; the price is low; the processing method is environment-friendly, safe, simple and efficient; the bacteria cellulose fiber-based carbon nanofiber knitted fabric gained after processing has wide application fields; and the potential economic benefit is huge.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Mulberry compound conditioning health-maintaining cake and preparation method thereof

InactiveCN105380166AEfficient use ofRetain activityFood ingredient functionsBiotechnologyLiver and kidney

The invention discloses a mulberry compound conditioning health-maintaining cake which comprises the following components by weight part: 30-50 parts of mulberry dried fruit, 0.1-10 parts of silkworm pupa protein peptide powder, 5-15 parts of black sesame, 5-15 parts of semen juglandis, 0.1-15 parts of donkey-hide gelatin, 0.1-10 parts of honey and 15-30 parts of compound adhesive. According to the concept of Chinese traditional health-maintaining and health-care through the traditional Chinese medicine and on the basis of the principle of traditional drug matching, the mulberry dried fruit is taken as a main ingredient, the drug property mutual-requiring auxiliary materials, such as the black sesame, the semen juglandis, the donkey-hide gelatin, the honey, and the like, are finely selected, the silkworm pupa protein peptide powder with oxidation-resisting and immunity-boosting functions is specially added, the activities of the functional factors, such as, anthocyanin in the raw materials are effectively reserved, and the compound adhesive preparation comprising folium mori polysaccharide is adopted, so that the prepared mulberry compound conditioning health-maintaining cake is convenient to eat, is excellent in color, fragrance, flavor and nutrition, and has the effects of regulating blood sugar level, tonifying qi and yin, nourishing liver and kidney, relaxing bowel and blacking hair and improving eyesight.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

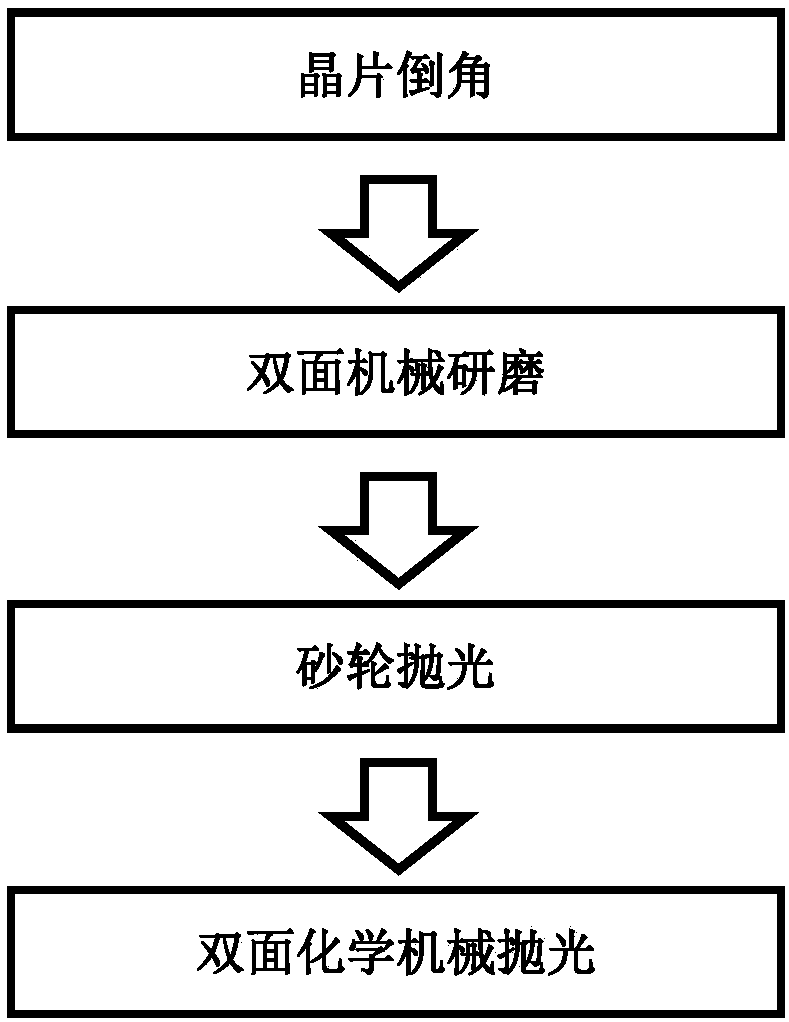

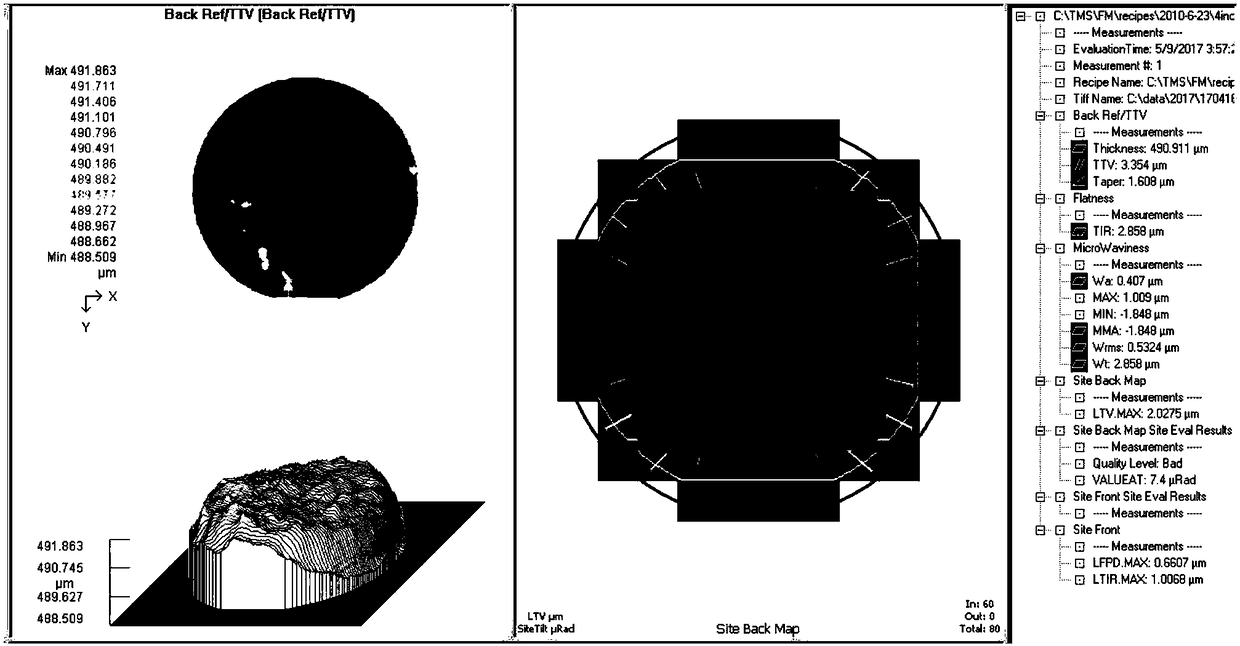

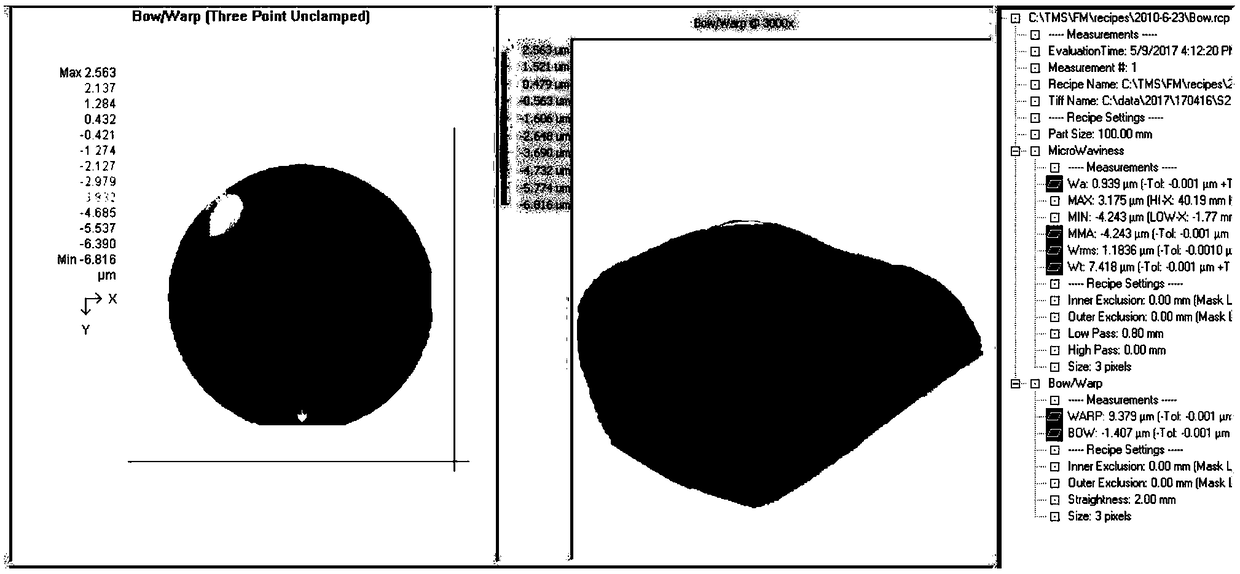

Efficient silicon carbide wafer machining method

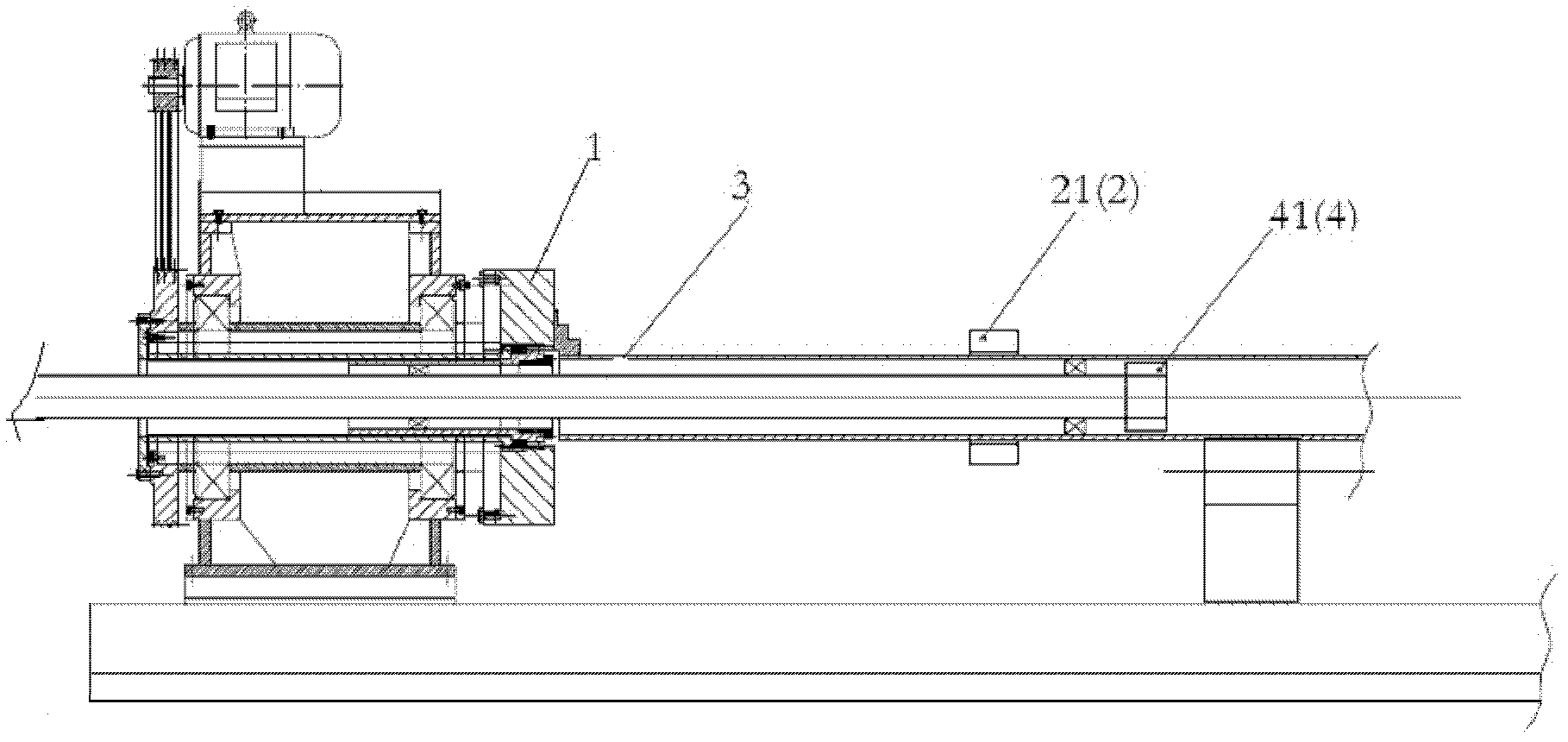

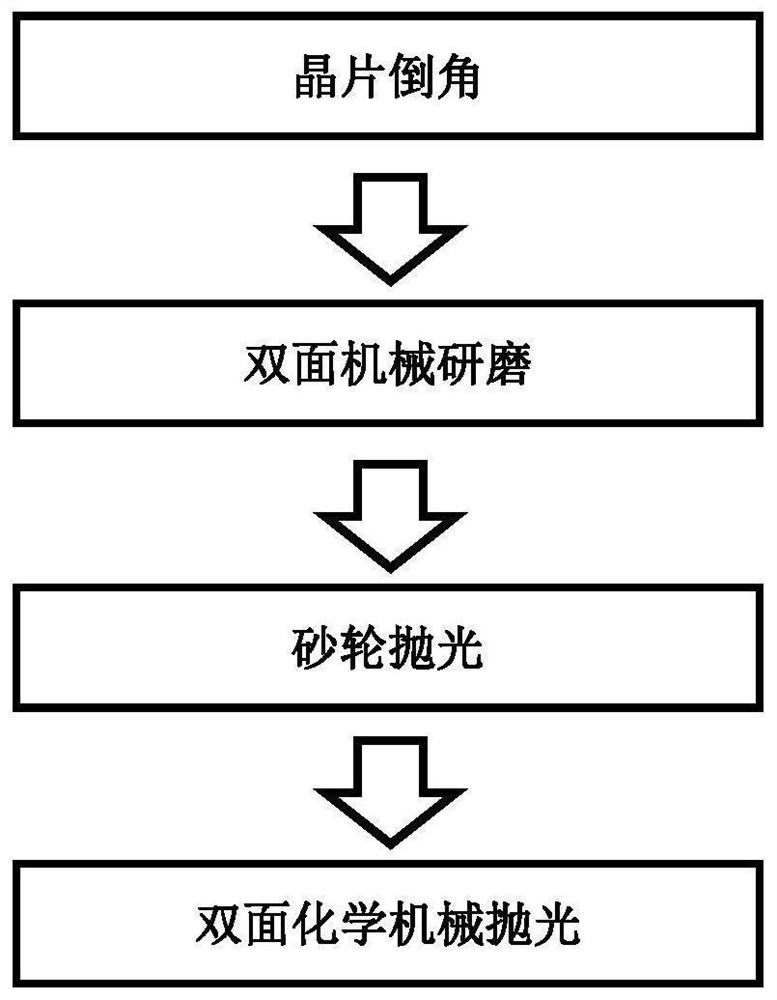

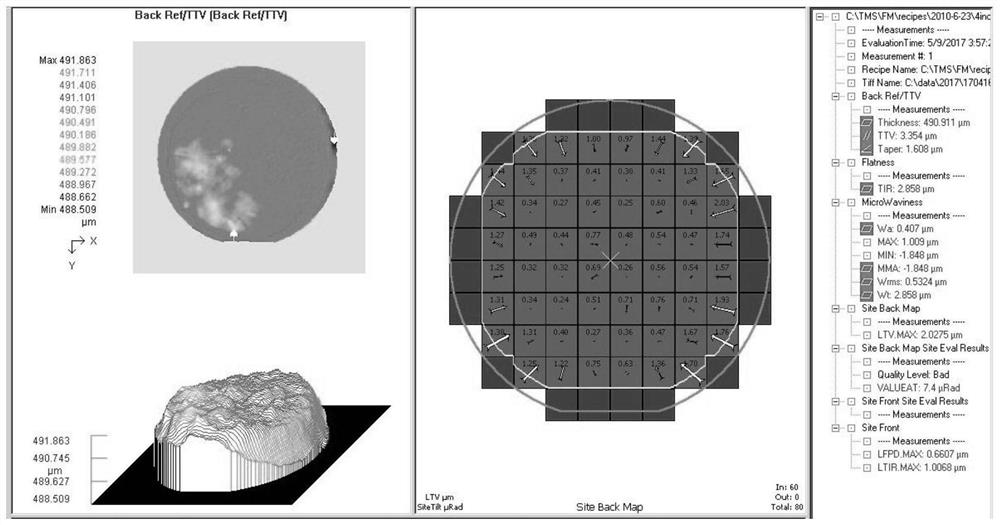

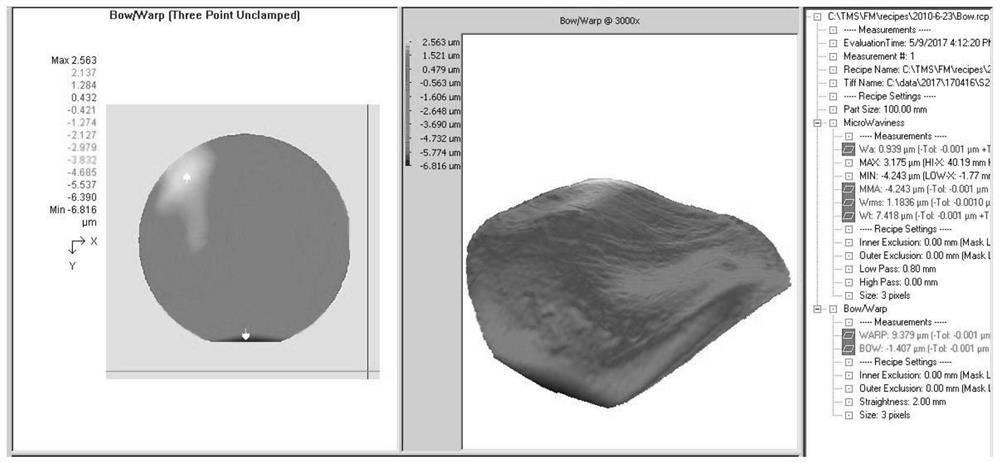

ActiveCN109129028AEfficient processing methodRapid processing methodLapping machinesLapping toolsSemiconductor materialsMachining process

The invention belongs to the technical field of semiconductor material machining and particularly relates to an efficient silicon carbide wafer machining method. The machining method includes wafer chamfering, double-face mechanical lapping, grinding wheel polishing and double-face chemical mechanical polishing. By means of the efficient silicon carbide wafer machining method, diamond grinding wheel polishing is linked with double-face mechanical lapping and double-face chemical mechanical polishing, a waxed wafer attaching procedure in a traditional single-face machining method is abandoned,the machining technology process is greatly optimized, meanwhile, the automation degree and precision of wafer machining are improved, and silicon carbide wafers low in warping degree and high in surface quality are obtained. By means of the efficient silicon carbide wafer machining method, the wafer machining process is greatly simplified, the machining efficiency is improved, and commercializedlarge-scale production is facilitated.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD +2

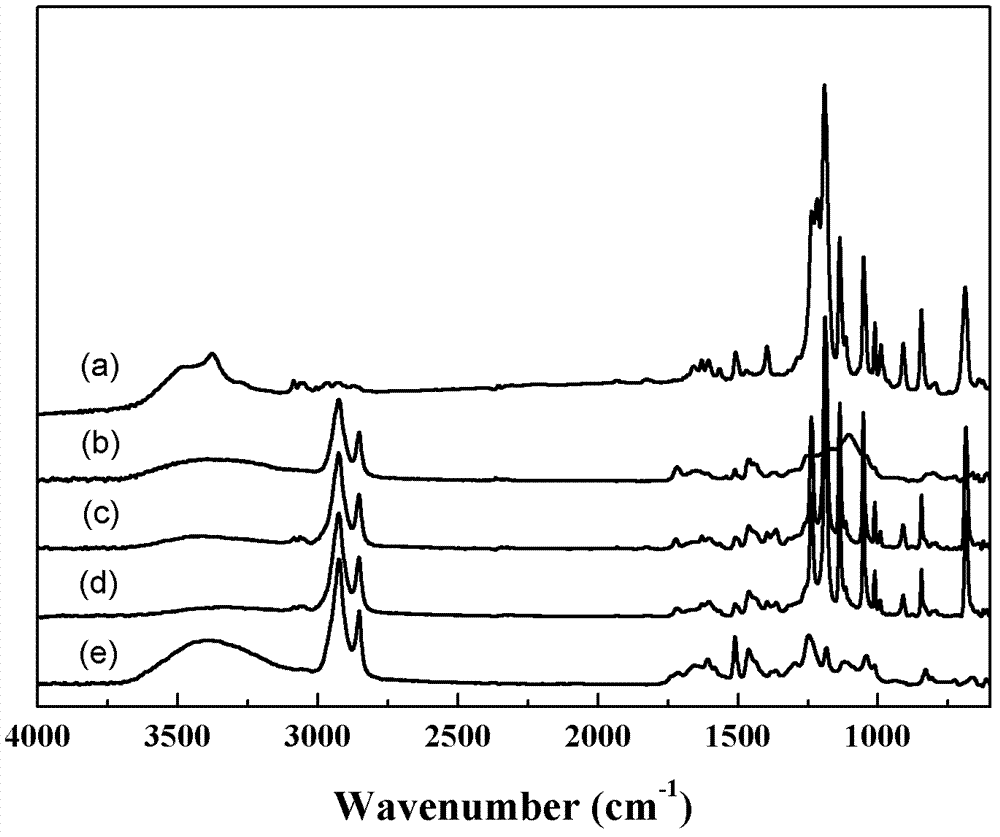

Sulphur-modified thermosetting polymer proton exchange membrane and preparation method thereof

InactiveCN103367781ASimple processing methodEfficient processing methodSolid electrolyte fuel cellsRubber materialPolymer science

The invention belongs to the field of polymer electrolyte materials for fuel cells, and particularly relates to a sulphur-modified thermosetting polymer proton exchange membrane and a preparation method thereof. The proton exchange membrane comprises a base body rubber material, a metal unsaturated sulfonate, a vulcanizing activator, a vulcanizing accelerator and sulphur. According to the preparation method, in-situ sulfonation modification and in-situ sulphur modification of rubber are simultaneously completed in a high-temperature hot-pressing process, sulfonic acid groups are effectively grafted on a rubber molecular chain, and a large amount of cyclical sulfides is generated, thus the glass-transition temperature of the rubber is greatly increased, the rubber is transformed into thermosetting plastics, and therefore excellent size stability, heat stability, chemical stability and electrochemical stability are endowed to the proton exchange membrane. The preparation method provided by the invention is simple in process, high in efficiency and low in cost, and is environmental-friendly; the prepared sulphur-modified thermosetting polymer proton exchange membrane has the advantages of high proton conductivity, low methanol permeability, high size stability and the like, and can meet the use requirement of a direct-methanol fuel cell.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Processing method for multi-flavor thin-skin walnut and walnut prepared by same

ActiveCN102423091BSimple processing methodEfficient processing methodFood preparationWalnut NutProcess engineering

The invention relates to the technical field of production and processing of walnut products, in particular to a processing method for a multi-flavor thin-skin walnut and the walnut processed by the processing method. The processing method comprises the following process steps of: selecting a thin-skin walnut; cleaning, drying and cracking; preparing a liquid; soaking the walnut in a seasoning liquid at high pressure for 24 hours; removing a residual liquid in the walnut by using a food dryer; placing the walnut into an electro-thermostatic blast oven for roasting; controlling the temperature to be about 100DEG C for 2 hours; cooling the roasted walnut; and bagging, vacuumizing and sealing. According to the processing method disclosed by the invention, a traditional production process of easily-cracked nuts is improved from the selecting and processing method; and the thin-skin walnuts from Sinkiang are selected and a high-pressure soaking technology is adopted, so that the process time is shortened and the quality of products is improved. The invention provides the simple and high-efficiency processing method with easiness in operation; peels of walnut products processed by the processing method are easily stripped; and the walnut products are convenience to eat, can be processed to obtain spiced and cream flavors and have fragrant and crisp mouthfeeling.

Owner:BEIJING UNIV OF AGRI

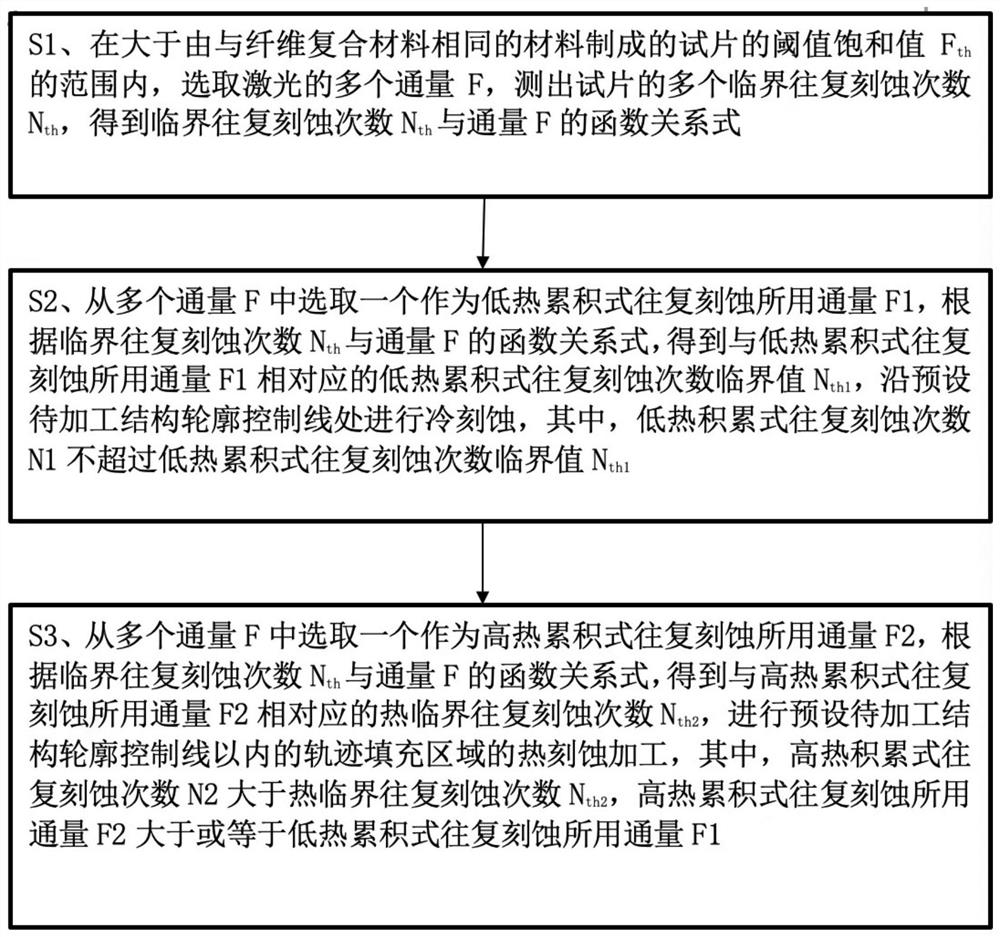

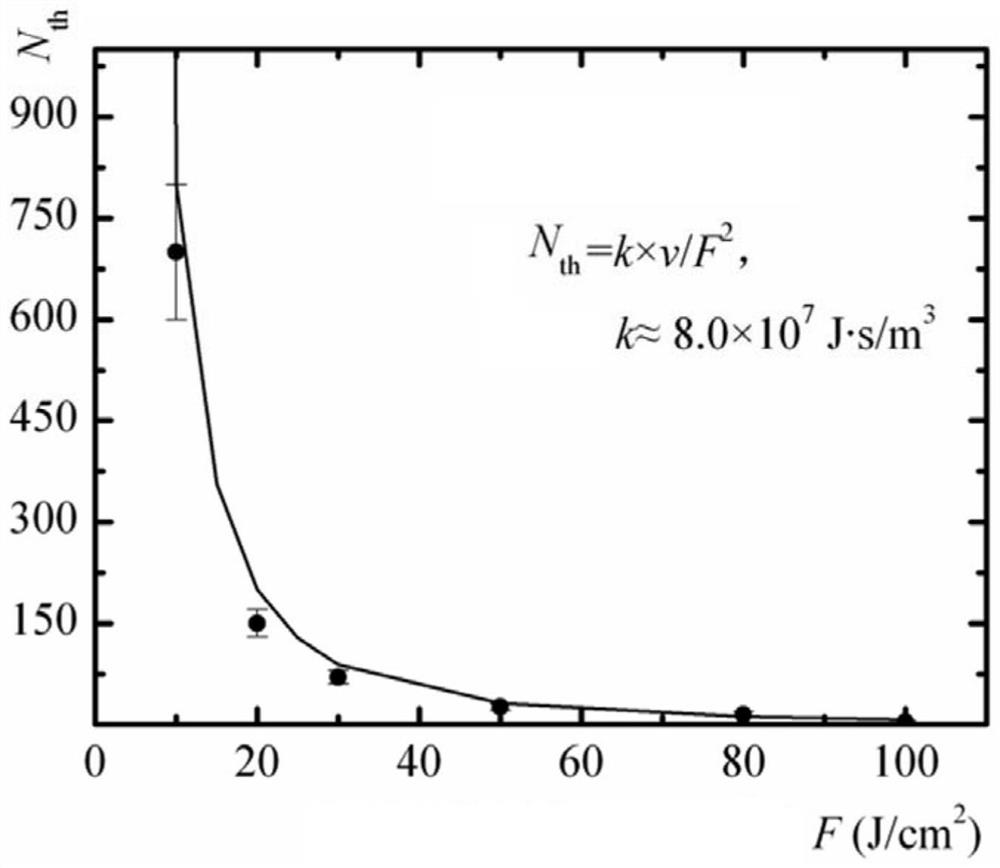

Ultrafast laser milling method for fiber composite material

PendingCN113977099AEfficient processingImprove efficiencyWelding/soldering/cutting articlesLaser beam welding apparatusEtchingFibrous composites

The invention relates to an ultrafast laser milling method for a fiber composite material, wherein the material comprises the steps: S1, in a range greater than a threshold saturation value (Fth) of a test piece made of the same material as the fiber composite material, selecting a plurality of fluxes (F) of laser, and measuring a plurality of critical reciprocating etching times (Nth) to obtain a function relational expression between the critical reciprocating etching times (Nth) and the fluxes (F); S2, performing cold etching along a contour control line of a to-be-processed structure, wherein the low-heat accumulation type reciprocating etching times (N1) do not exceed the critical value (Nth1) of the low-heat accumulation type reciprocating etching times; and S3, performing hot etching processing on a track filling area within a preset to-be-processed structure contour control line, wherein the high-heat accumulation type reciprocating etching frequency (N2) is larger than the heat critical reciprocating etching frequency (Nth2). Precise and efficient ultrafast laser milling processing can be achieved, quantitative guidance is provided, the processing effect can be improved, and high repeatability is achieved.

Owner:BEIJING SATELLITE MFG FACTORY

Steel tube as well as processing method and processing equipment for steel tube

ActiveCN102443691BTo achieve the purpose of wear resistanceEfficient processing methodFurnace typesIncreasing energy efficiencyWear resistantHardness

The invention discloses a processing method for a steel tube. The processing method comprises the following steps of: carrying out inner wall quenching on the steel tube to enable the steel tube to integrally form a martensite structure; carrying out medium-temperature tempering on the outer wall of the steel tube, which is processed by an inner wall quenching process, to enable the outer wall to form a tempered troostite structure; and meanwhile, carrying out low-temperature tempering on the inner wall to enable the inner wall and part of adjacent outer wall to form a tempered martensite structure. Therefore, the inner wall of the processed steel tube has higher hardness and wear resistant; the outer wall of the processed steel tube has higher toughness; and the processed steel tube can completely meet the requirements of wear resistance and toughness. The invention also discloses processing equipment for the steel tube. The processing equipment comprises a clamper for clamping the steel tube, an inner wall quenching device of a quenching sensor as well as an outer wall tempering device of a tempering sensor, wherein the inner wall quenching device can be moved inside the steel tube; and the outer wall tempering device can be moved on the outer wall of the steel tube. The processing equipment can be used for simultaneously finishing the inner wall quenching process and the outer wall tempering process and has high processing efficiency. The invention further provides the steel tube obtained by the processing method and the processing equipment disclosed by the invention.

Owner:ZOOMLION HEAVY IND CO LTD

A kind of efficient silicon carbide wafer processing method

ActiveCN109129028BEfficient processing methodRapid processing methodLapping machinesLapping toolsCarbide siliconWafering

The invention belongs to the technical field of semiconductor material processing, and in particular relates to an efficient silicon carbide wafer processing method, including wafer chamfering, double-sided mechanical grinding, grinding wheel polishing, and double-sided chemical mechanical polishing. The invention adopts diamond grinding wheel polishing to connect double-sided mechanical grinding and double-sided chemical mechanical polishing, abandons the wax patch program in the traditional single-sided processing method, greatly optimizes the processing process, and improves the automation and efficiency of wafer processing. Precision, obtained silicon carbide wafers with low warpage and high surface quality. The inventive method greatly simplifies the wafer processing flow, improves processing efficiency, and is beneficial to commercial large-scale production.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD +2

Capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device and application

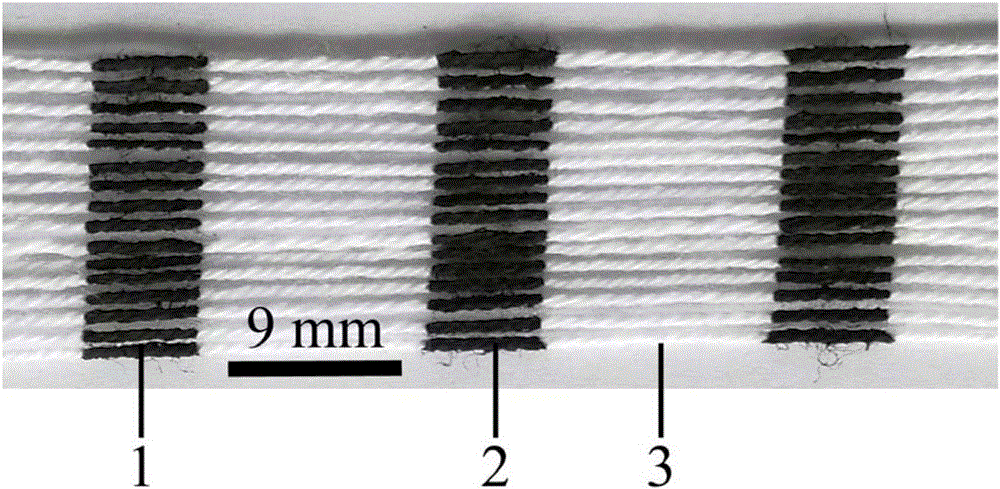

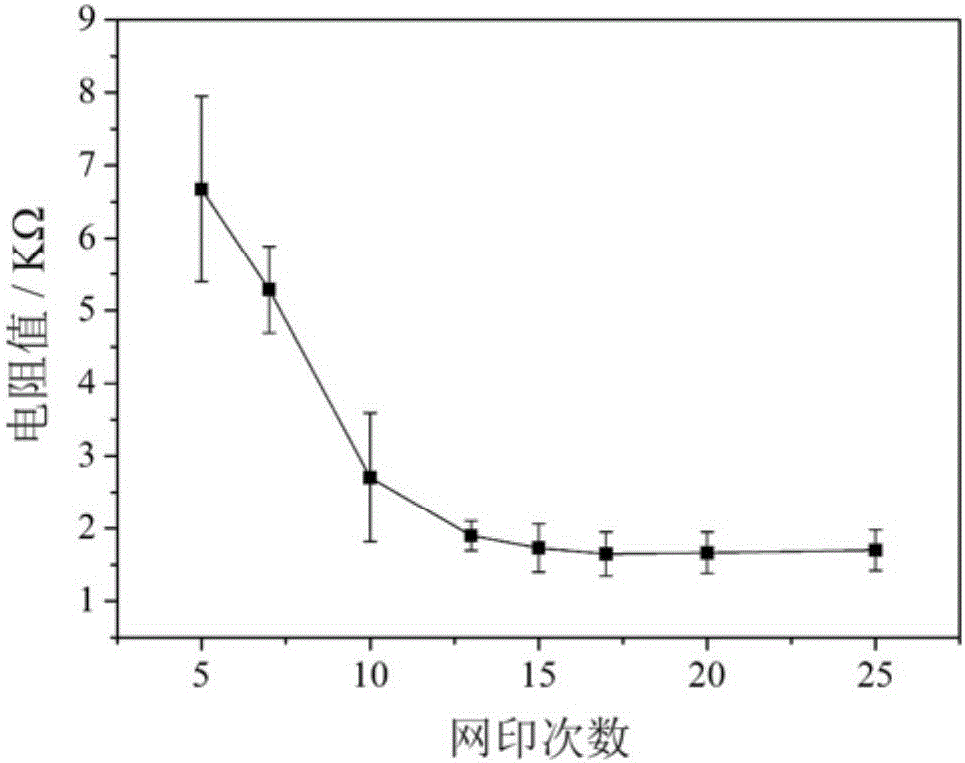

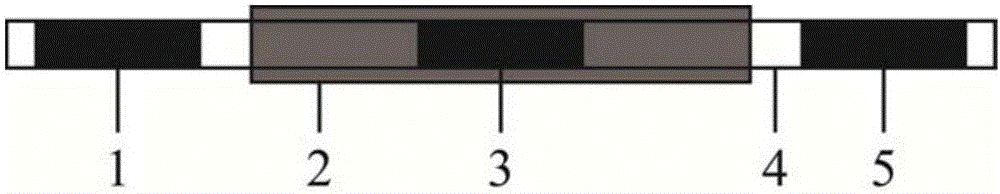

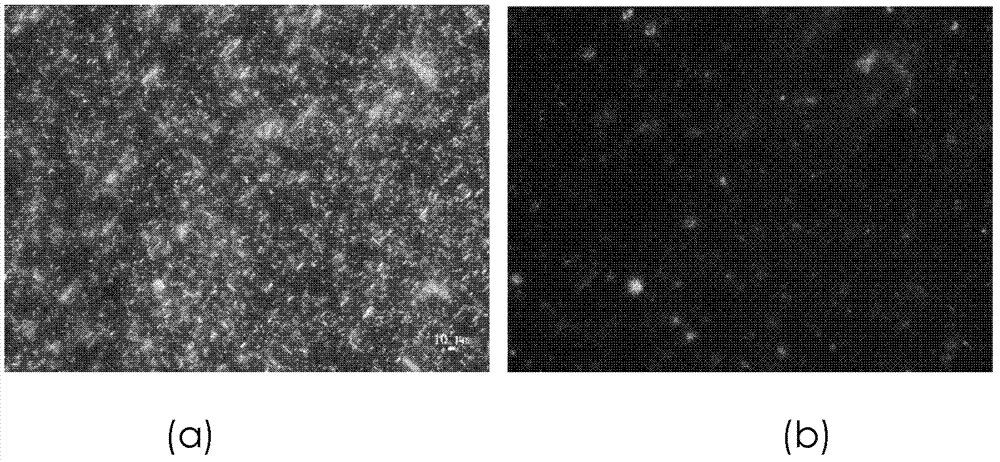

ActiveCN106353303AHigh resolutionControllable intervalChemiluminescene/bioluminescenceEngineeringLuminescence

The invention discloses a capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device, and a preparation method and the application thereof. The luminescence device consists of a capillary and a patterning line electrode, wherein the patterning line electrode consists of not less than three wire base electrodes and bare wire areas; the wire base electrodes are manufactured by conductive carbon paste; the wire base electrodes on two sides are driving electrodes; the wire base electrode between the driving electrodes is a bipolar electrode; an area between the every two wire base electrodes is the bare wire area; the capillary coats the patterning line electrode, needs to coat all bipolar electrodes, and simultaneously can not be in contact with the driving electrode. According to the luminescence device, the capillary micro-channel is applied to the line of the patterning carbon electrode for the first time to manufacture the capillary micro-channel assistant wire base microfluidic bipolar electrode electrochemical luminescence device. The integration device has the remarkable advantages that the loading speed of a sample is high and the samples can be evenly distributed on the patterning wire electrode.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Original-flavor sauce and processing method thereof

The invention relates to an original-flavor sauce which comprises the following raw materials in parts by weight: 1-300 parts of hot pepper, 1-100 parts of onions, 1-100 parts of garlic bulbs, 1-400 parts of edible oil, 0.1-30 parts of edible salt, 0.1-50 parts of white granulated sugar, and 0.1-30 parts of white spirit. The original-flavor sauce has the characteristics of being fresh and delicious in taste, safe to eat and long in shelf life, and can also achieve high-efficiently antiseptic and fresh-keeping effects without addition of any additive; furthermore, the original-flavor sauce is rich in nutritional ingredients such as vitamins, capsaicin, protein, mineral substances and the like, thus being suitable for all consumers to eat, and providing safe, relieved and delicious seasoning for people; in addition, a processing method has the characteristics of being high-efficiency, environment-friendly and cost-saving; and compared with the prior art, the working efficiency is greatly improved, and the production cost is saved.

Owner:刘少英

Preparation method of polymer matrix proton exchange membrane (PEM) with cross-linked structure

ActiveCN102775628BEvenly dispersedPromote practical developmentCell component detailsFuel cell detailsCross-linkPermeability coefficient

The invention relates to a preparation method of a polymer matrix proton exchange membrane (PEM) with a cross-linked structure, belonging to the field of battery electrolyte materials. The PEM is prepared by carrying out mechanical blending dispersion on matrix polymer material, unsaturated metal organic sulfonate, peroxide and auxiliary crosslinking agent, carrying out reaction in situ at the temperature of 140-200 DEG C, treating the product of the reaction by deionized water and sulfuric acid solution, and drying; and the PEM comprises the components in parts by weight: (1) 100 parts of matrix polymer material, (2) 20-150 parts of unsaturated metal organic sulfonate, (3) 1-20 parts of peroxide and (4) 0-5 parts of auxiliary crosslinking agent. In the molding process, organic solvent is not needed; and the preparation method is simple, high in efficiency, environment-friendly and low in cost. The prepared PEM has the proton conductivity approximate to Nafion (reaching up to the order of magnitude of 10<-2> / cm) and the methanol permeability coefficient far less than Nafion at the temperature of 20-80 DEG C, thus meeting the using requirement of a direct methanoi fuel cell.

Owner:BEIJING UNIV OF CHEM TECH

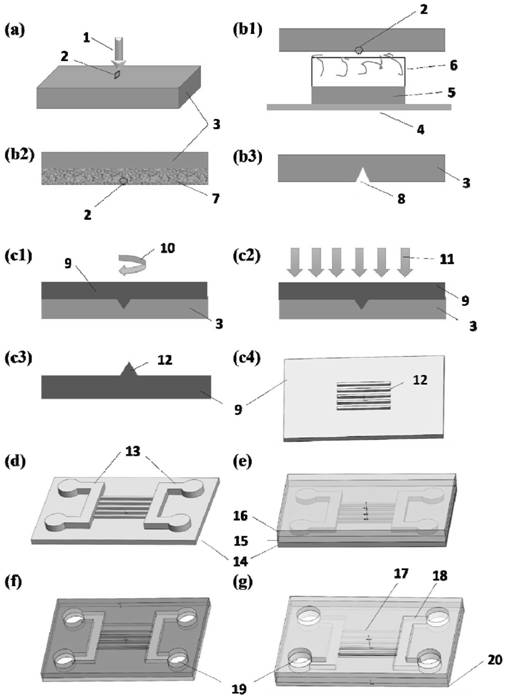

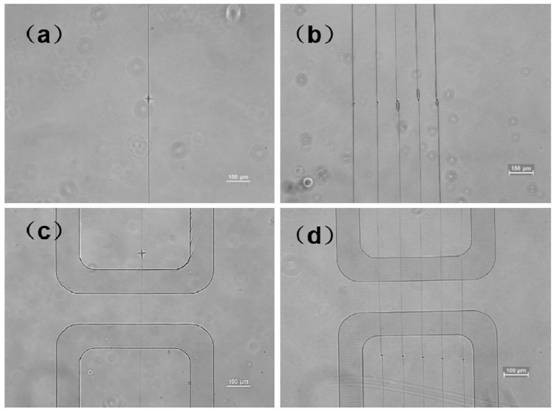

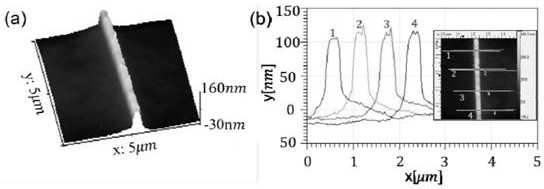

Nanofluidic chip based on nanocracks and processing method thereof

PendingCN114433260AHigh repeatabilityEfficient processing methodLaboratory glasswaresPhysicsSiloxane

The invention provides a nanofluidic chip based on nanocracks and a processing method thereof. The nano-fluidic chip is formed by bonding a polydimethylsiloxane channel layer and a glass substrate, the polydimethylsiloxane channel layer contains a micron channel and at least one nano channel, the nano channel is connected with the micron channel, the tail end of the micron channel is connected with the outside through a liquid storage tank, and the liquid storage tank is used for adding and extracting a nano-fluidic chip sample. The processing method is simple, efficient and rapid processing of a single nano-channel array or a multi-nano-channel array can be achieved, and the length, the position and the size of the nano-channel are accurate and controllable. The problems of long time consumption, high cost, complex operation and the like of a traditional semiconductor processing technology are solved. The processed micro-nano fluidic chip can be used in the fields of biosensing, chemical analysis, micro-nano energy collection and the like based on the nanofluidic technology.

Owner:DALIAN MARITIME UNIVERSITY

Large-aperture optical mirror surface rapid polishing method based on multiple polishing systems

ActiveCN112775724ASolve the problem of long production cycleEfficient processingOptical surface grinding machinesAutomatic grinding controlPolishingMaterials science

The invention provides a large-aperture optical mirror surface rapid polishing method based on multiple polishing systems, and belongs to the field of optical element processing. The problems that an existing large-diameter optical mirror face is long in processing period, and the production efficiency is affected are solved. A plurality of polishing systems are included, after mirror surface milling and grinding forming treatment and optical mirror positioning and fixing are carried out, and surface shape rough grinding, surface shape fine grinding, surface shape grinding and repairing and polishing are carried out through the multiple polishing systems till surface shape processing is completed. The large-aperture optical mirror surface rapid polishing method based on the multiple polishing systems is mainly used for quick polishing of large-aperture optical mirror surfaces.

Owner:CHANGGUANG SATELLITE TECH CO LTD

Machining method of micropore polyurethane sealing ring and tool clamp used for method

PendingCN109807360AIncrease productivityImprove production yieldTurning toolsTool holdersNumerical controlEngineering

The invention discloses a machining method of a micropore polyurethane sealing ring. The method comprises the steps of producing a micropore polyurethane hollow casting and cutting the micropore polyurethane hollow casting into the micropore polyurethane sealing ring. The invention further discloses a turning-lathe tool clamp used for the method. The tool clamp comprises a core rod and a supporting shaft, the core rod is cylindrical, and the supporting shaft is in a ring columnar shape, and coats the core rod. The cylindrical micropore polyurethane hollow casting is subjected into injection molding, a thin blade turning knife tool or numerical control automatic turning lathe is used for cutting the micropore polyurethane hollow casting into the needed-size seal ring, the production efficiency and the yield of the micropore polyurethane sealing ring are improved, and the more efficient machining method is provided for large-scale production of the micropore polyurethane sealing ring.

Owner:洛阳凯众减震科技有限公司

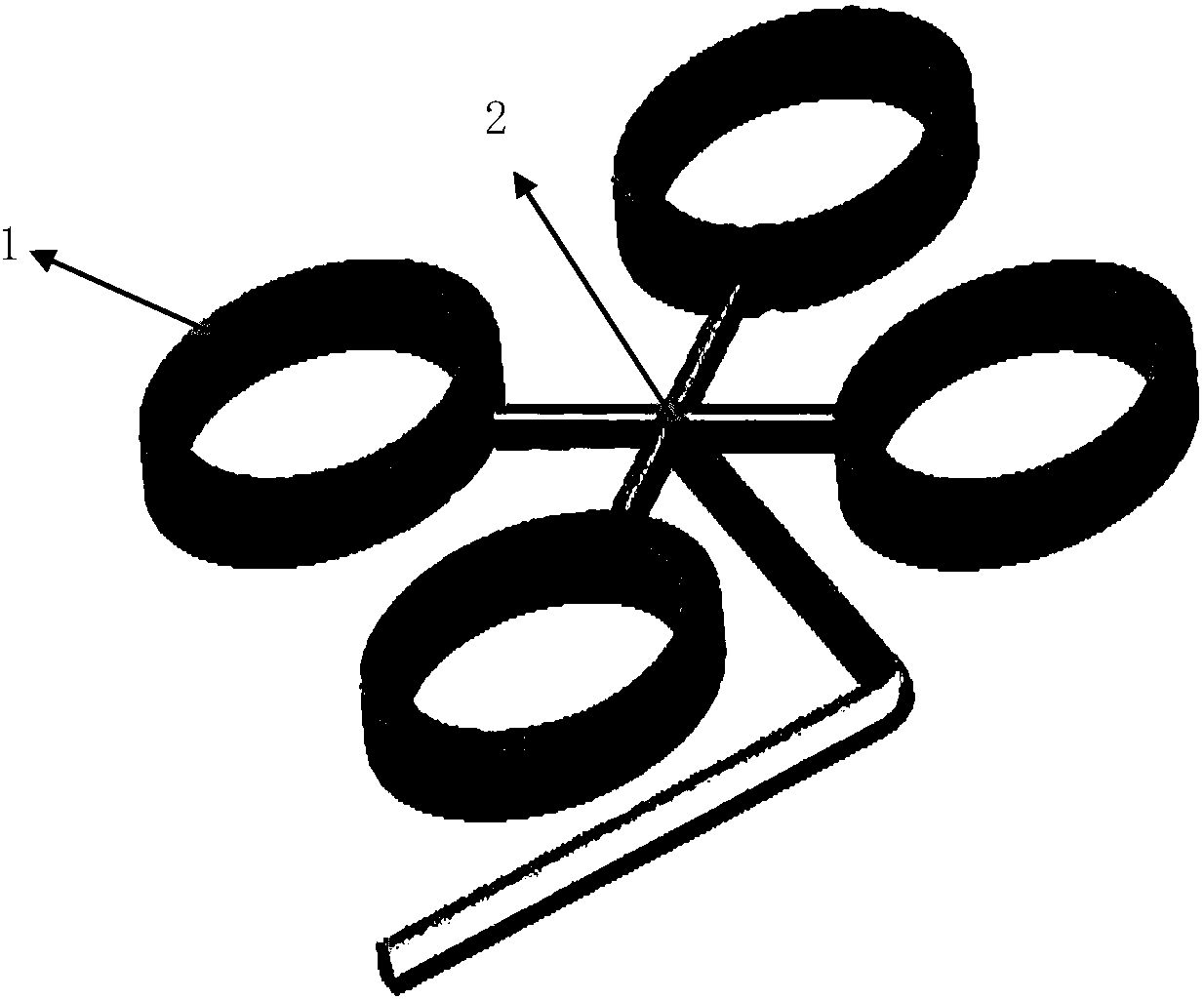

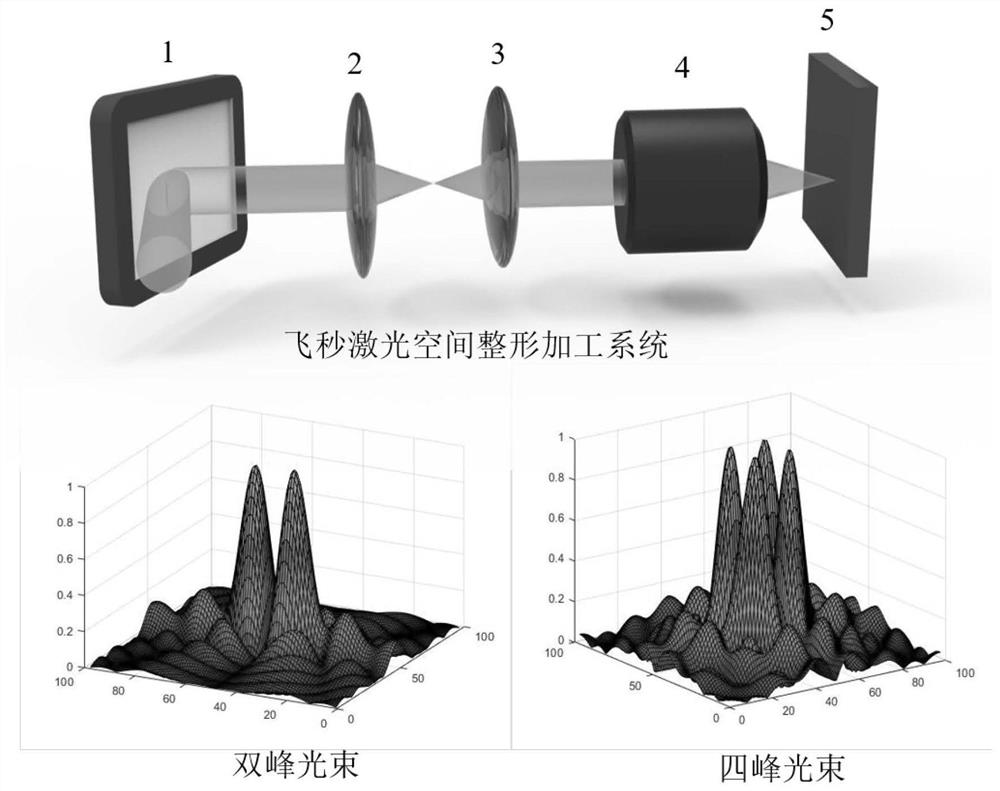

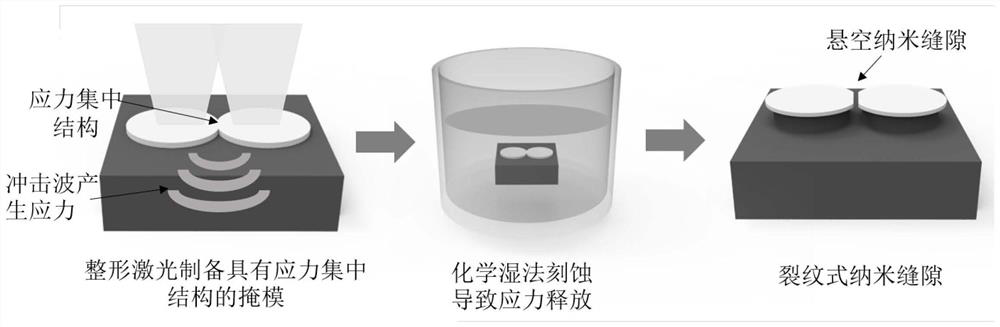

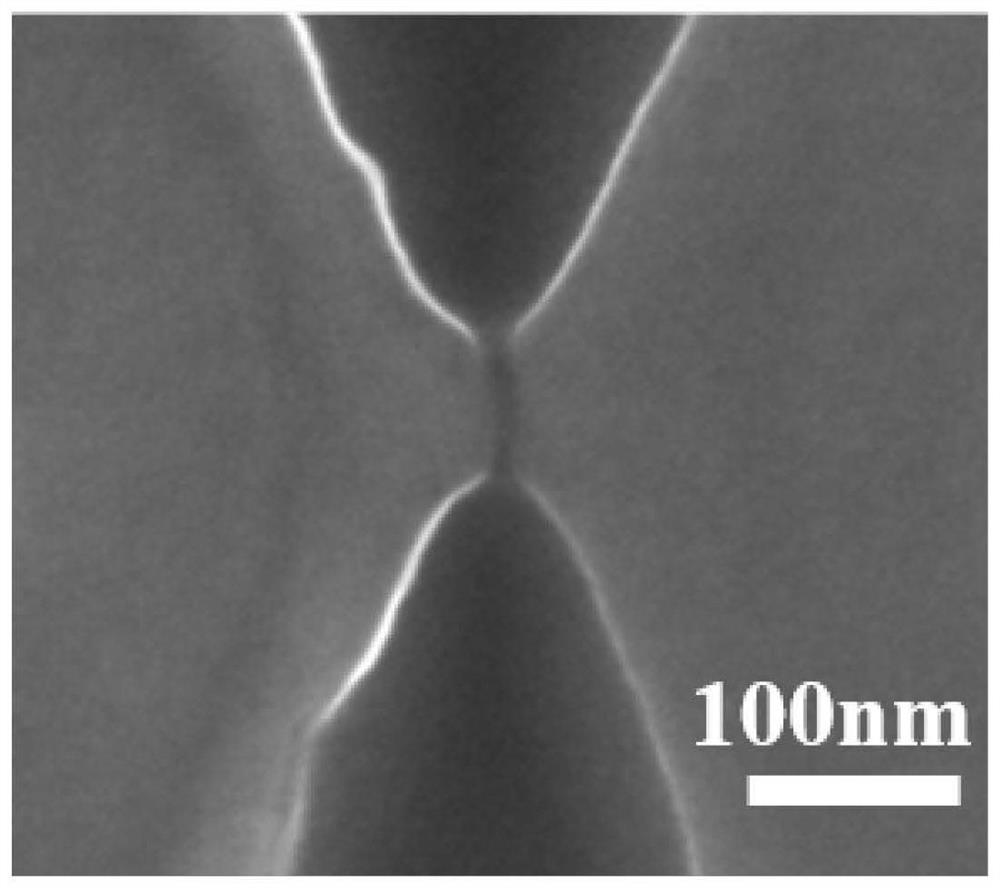

A femtosecond laser-based preparation method for cracked nano-gap structure

ActiveCN113247859BNo maskEfficient processing methodDecorative surface effectsNanotechnologyStress concentrationEtching

The invention relates to a preparation method of a crack-type nano-slit structure based on a femtosecond laser, and belongs to the technical field of laser application. The invention transforms the traditional Gaussian femtosecond laser beam into a double-peak or multi-peak beam through the space domain shaping technology. Based on the femtosecond laser-induced material amorphization and the femtosecond laser-induced shock wave phenomenon, a structure with multiple stress concentrations is induced on the silicon surface. Amorphous silicon etch mask. Such an etching mask with a stress-concentrating structure is the key to the formation of nanocrack propagation during wet etching. In the subsequent wet etching process, under the influence of solution undercutting, the etching mask with stress concentration structure releases the stress due to being etched into a suspended state, and at the same time, nanometers are generated at the stress concentration place under the action of the surface tension of the solution. The cracks propagate, forming nano-gap structures of extremely small size (below 10 nm).

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

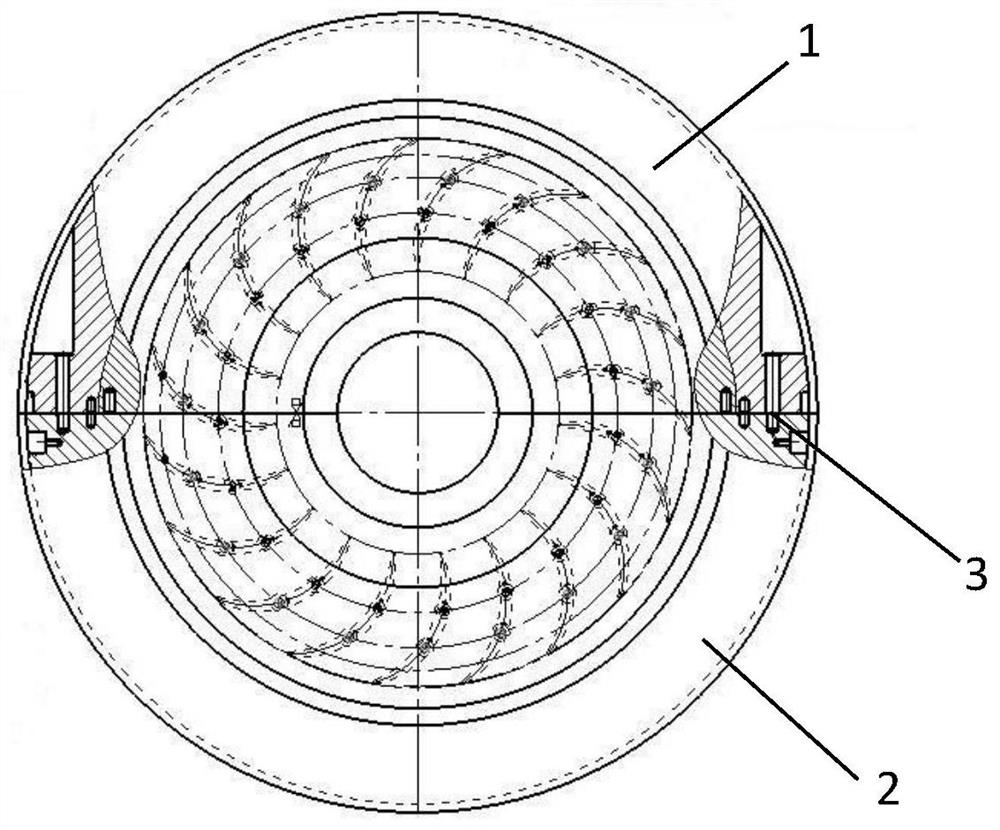

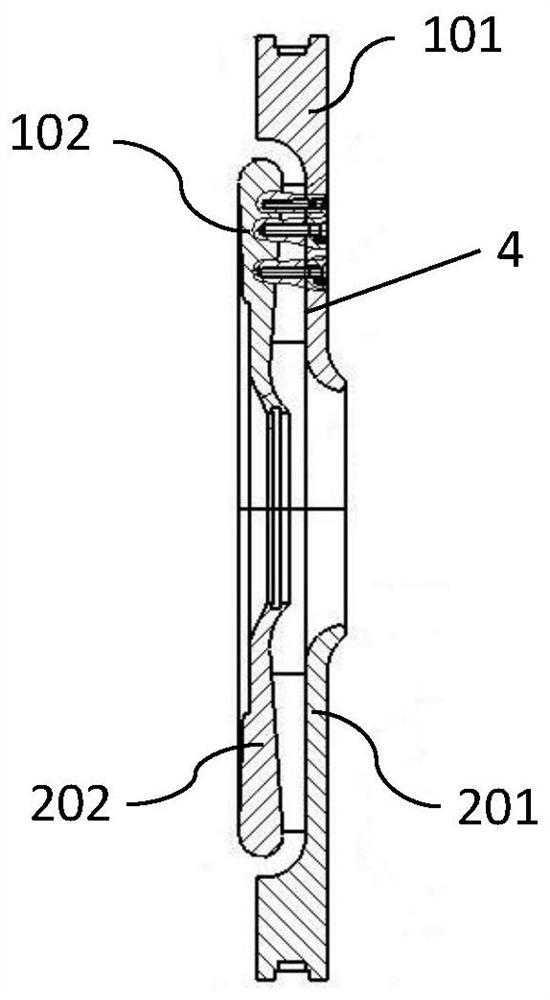

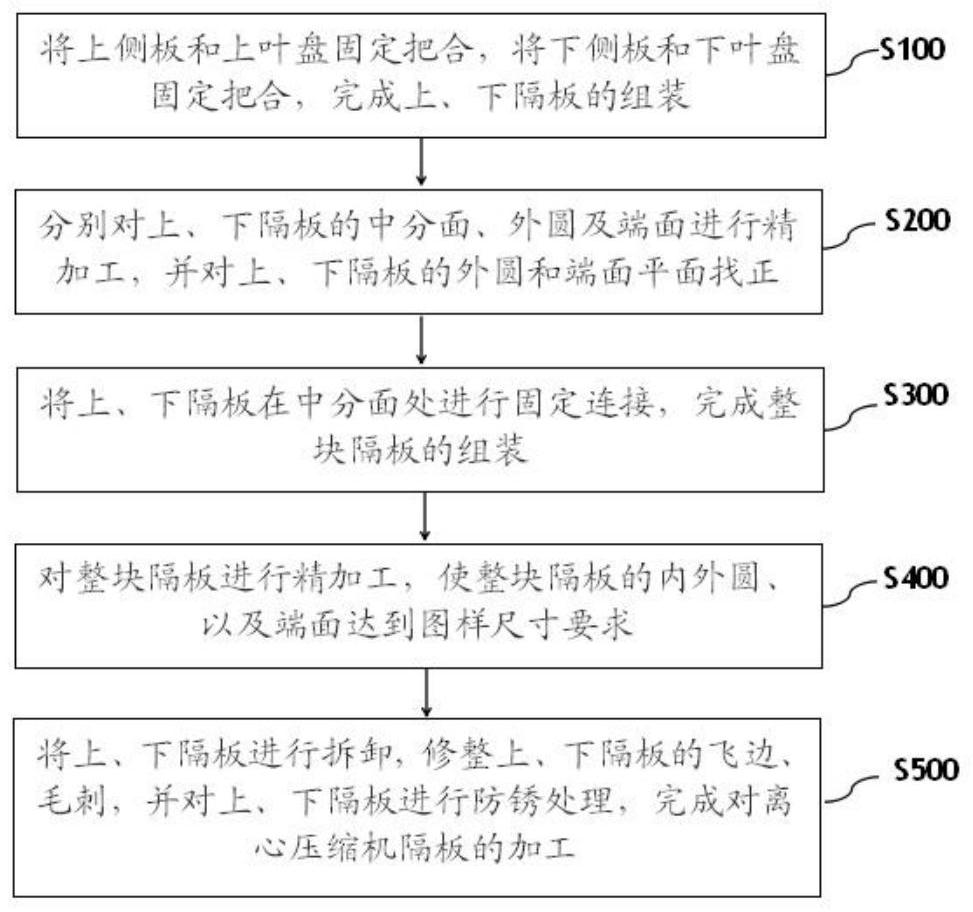

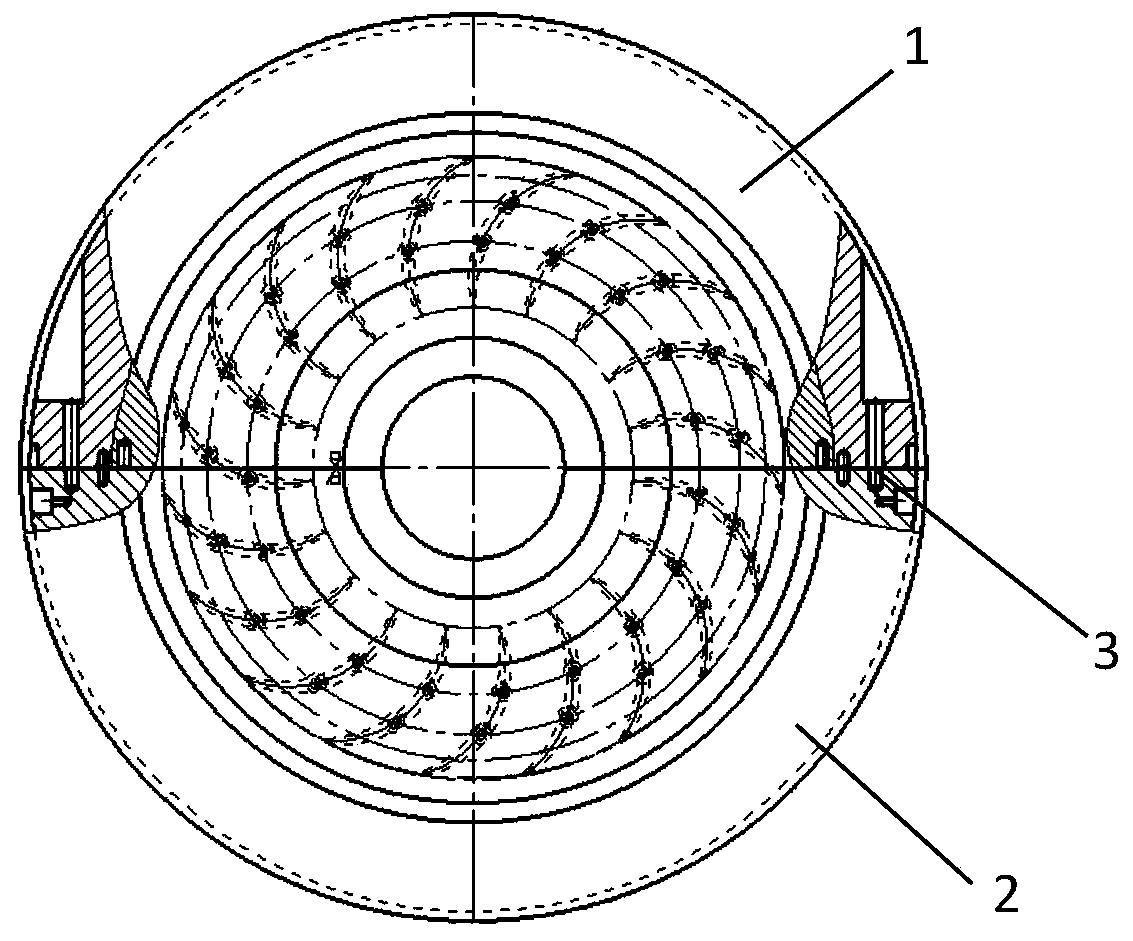

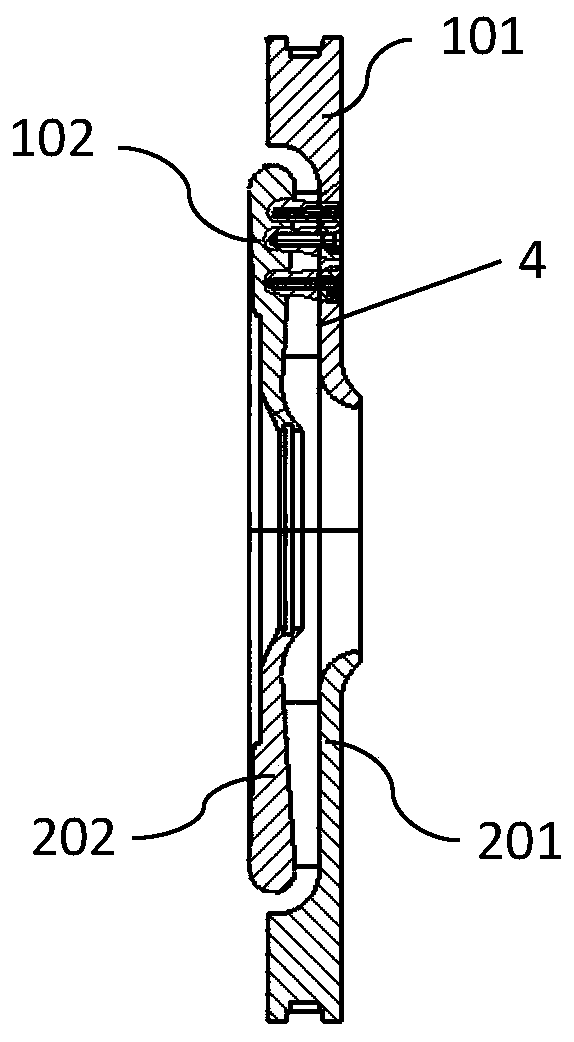

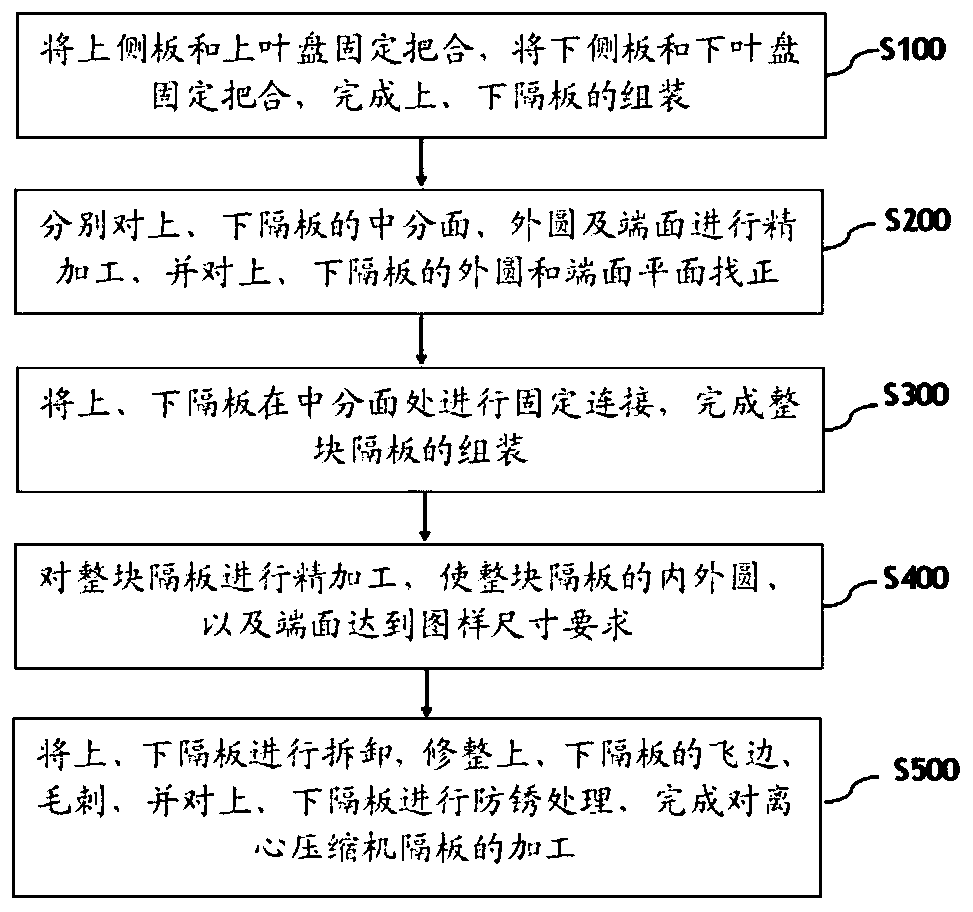

A processing method for centrifugal compressor diaphragm

ActiveCN110102970BThe processing method is practicalEfficient processing methodPump componentsPumpsStructural engineeringMechanical engineering

The invention discloses a processing method for a diaphragm of a centrifugal compressor, which includes: fixing the upper side plate and the upper blisk together, fixing the lower side plate and the lower blisk together, and completing the assembly of the upper and lower partitions; Finish the mid-section, outer circle and end surface of the upper and lower partitions respectively, and align the outer circle and end plane of the upper and lower partitions; fix the upper and lower partitions at the mid-section , complete the assembly of the whole partition; finish the whole partition, so that the inner and outer circles and end faces of the whole partition meet the size requirements of the drawing; disassemble the upper and lower partitions, and trim the upper and lower partitions Flash, burrs, and anti-rust treatment on the upper and lower partitions, complete the processing of centrifugal compressor partitions. The invention realizes a practical and high-efficiency preparation method for processing the diaphragm of the centrifugal compressor, and solves the technical blank of the diaphragm of the centrifugal compressor at present.

Owner:SHENYANG TURBO MASCH CORP

Processing method of centrifugal compressor clapboard

ActiveCN110102970AThe processing method is practicalEfficient processing methodPump componentsPumpsEngineeringCentrifugal compressor

The invention discloses a processing method of a centrifugal compressor clapboard. The processing method of the centrifugal compressor clapboard comprises the steps of fixedly combining an upper sideplate and an upper blade disk, fixedly combining a lower side plate and a lower blade disk, and accomplishing the assembling of an upper clapboard and a lower clapboard; finish-machining center parting surfaces, excircles and end surfaces of the upper clapboard and the lower clapboard; aligning the excircles and planes of the end surfaces of the upper clapboard and the lower clapboard; fixedly connecting the upper clapboard and the lower clapboard on the center parting surfaces, and accomplishing the assembling of the whole clapboard; finish-machining the whole clapboard, and enabling an innercircle, an excircle and the end surface of the whole clapboard to meet the dimensional requirement of a drawing; disassembling the upper clapboard and the lower clapboard, trimming flashing and burrsof the upper clapboard and the lower clapboard; and derusting the upper clapboard and the lower clapboard, so that the processing of the centrifugal compressor clapboard is accomplished. The invention realizes the practical and high-efficiency processing method of the centrifugal compressor clapboard, and fills the technical blank of a current centrifugal compressor clapboard.

Owner:SHENYANG TURBO MASCH CORP

Manganous oxide doped isomelanin nano material with electromagnetic shielding function, preparation method of thin film and product

PendingCN114874433AEfficient useEasy Process SynergyMagnetic/electric field screeningManganese oxides/hydroxidesThin membraneChemistry

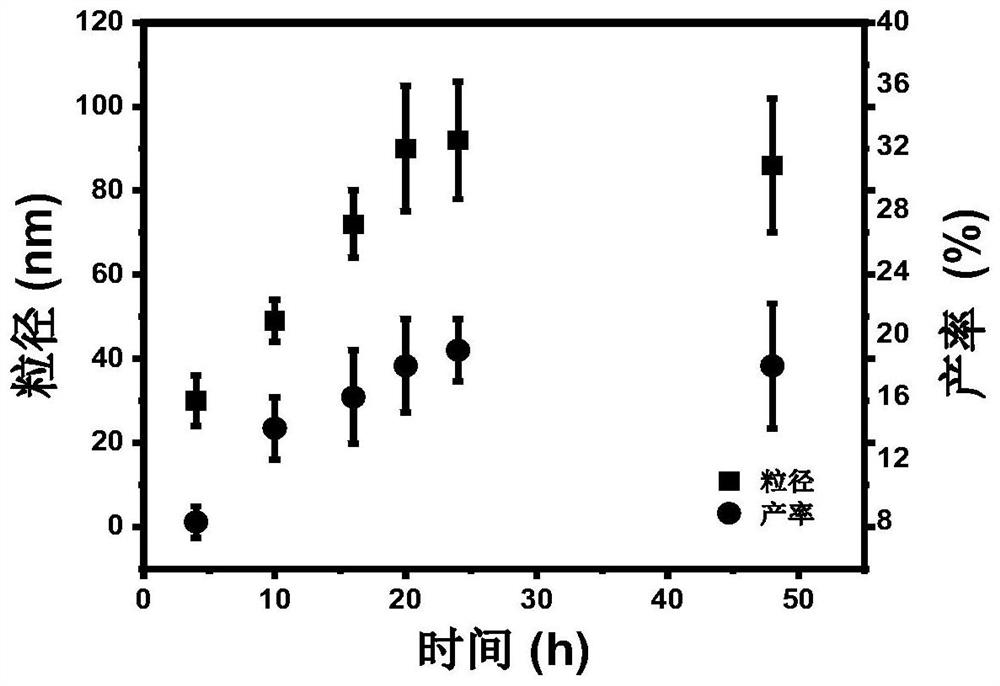

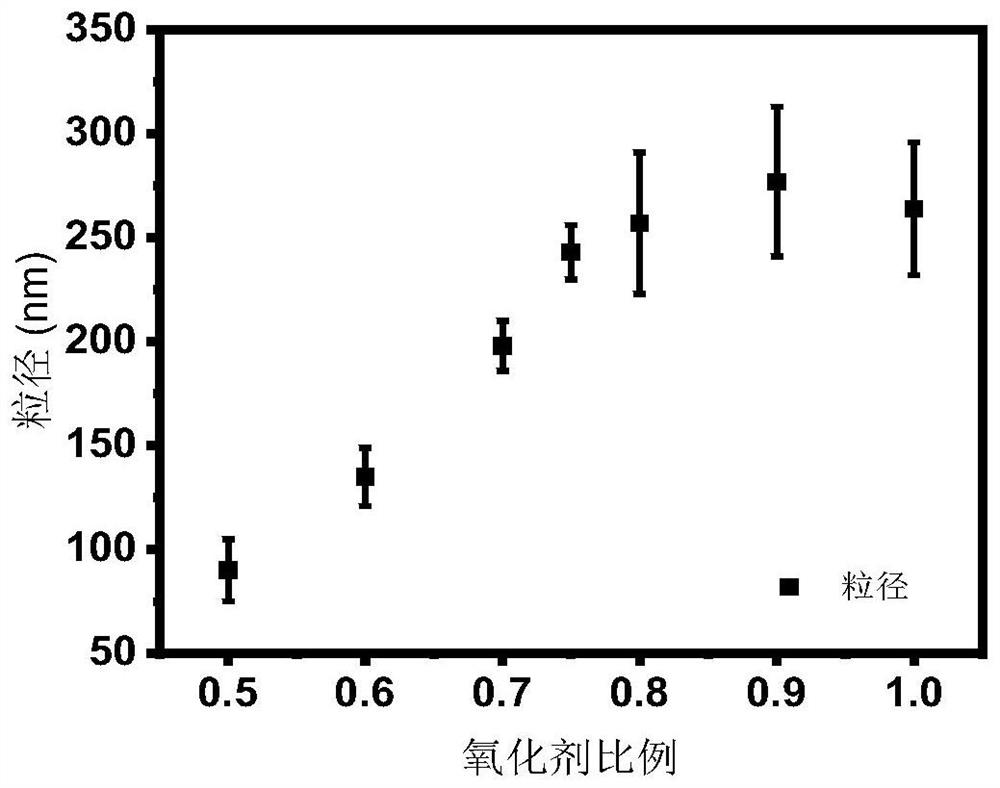

The invention provides a manganous oxide doped isomelanin nanometer material with an electromagnetic shielding function, a preparation method of a film and a product, and the preparation method of the nanometer material comprises the following steps: preparing a 1, 8-dihydroxy naphthalene solution with a solvent being a mixed solvent of acetonitrile and water; the method comprises the following steps: slowly adding a potassium permanganate aqueous solution into a 1, 8-dihydroxynaphthalene solution, stirring to obtain a black turbid solution, centrifuging, and washing to obtain an isomelanin nano material; and carrying out heat treatment on the isomelanin nano-material in a protective atmosphere to obtain the manganous oxide doped isomelanin nano-material. The preparation method of the nano-film comprises the following steps: mixing the isomelanin nano-material with a polytetrafluoroethylene dispersion liquid, adding water, carrying out ultrasonic dispersion, drying, and rolling to obtain the manganous oxide doped isomelanin nano-film. According to the invention, multivalent metal ions are adopted as an oxidizing agent, metal is introduced into a melanin material, and a metal loading system with uniform valence is obtained through heat treatment. The thin film has a good electromagnetic shielding function, and thin film materials with different grade requirements can be achieved simply and conveniently by adjusting the thickness.

Owner:SICHUAN UNIV

Garlic-flavor sauce and processing method thereof

InactiveCN107048333AGreat tasteFood safetyAlcoholic food ingredientsLipidic food ingredientsVegetable oilFood flavor

The invention provides garlic-flavor sauce, prepared from the following raw materials in parts by weight: 1-30 parts of chili, 1-10 parts of garlic, 0.1-5 parts of fermented soya beans, 0.1-5 parts of minced ginger, 0.1-3 parts of edible salt, 0.1-3 parts of white wine and 1-30 parts of vegetable oil. The garlic-flavor sauce provided by the invention has the advantages of good mouthfeel, edible safety and long shelf life, the sauce has efficient antiseptic and freshness-preserving effects without adding any additive, so a safe food is provided for people; and the processing method has the characteristics of high efficiency, environmental protection and simple operation, effectively prolongs the shelf life of the sauce, greatly improves the working efficiency and reduces the production cost.

Owner:刘少英

Preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber

InactiveCN103184586BLow priceWide variety of sourcesFibre chemical featuresCarbon fibersEconomic benefits

The invention relates to a preparation method of bacterial-cellulose-fiber-based nano-grade carbon fiber. According to the invention, a bacterial cellulose wet film is adopted as a substrate raw material. The prepared nano-grade carbon fiber is a product obtained after pyrolytic carbonization and graphitization of ultrafine bacterial cellulose fiber processed through an acupuncture carding refining treatment. The bacterial-cellulose-fiber-based nano-grade carbon fiber preparation method provided by the invention is safe, simple, and highly efficient, and has the advantages of wide raw material source, low price, and environment-friendly processing method. The bacterial-cellulose-fiber-based nano-grade carbon fiber obtained by processing has wide application field and great potential economic benefit.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of color-changing hot stamping film and its manufacturing method

ActiveCN103921582BIncrease contrastImprove visual recognitionDuplicating/marking methodsMetal layered productsHot stampingColor effect

The invention relates to a variable color thermoprinting membrane and a making method thereof. The variable color thermoprinting membrane includes a base membrane, a release layer, a transflective metal layer, an information medium layer, a total reflecting metal layer and a hot melt adhesive layer, the information medium layer is a yieldable organic medium coating, steps with different heights are arranged on the at least one surface of the information medium layer or in the information medium layer, and the height of each of the steps corresponds to the Fabri-Perot cavity of a color. The above Fabri-Perot cavities enable a plurality of variable color zones, variable color figures and characters to be formed on a same hot stamping membrane, can realize the change of the color effect with the viewing angle under different polarization, and the color of the novel thermoprinting membrane changes. The thermoprinting membrane is made in a roll-to-roll manner, a heat evaporation coating partially substitutes a vacuum sputter coating, the organic medium coating is made in an efficient nano-coating manner, and steps and a micro-nano structure are obtained through an impression means, and the method is simple and efficient, and is suitable for wide format production.

Owner:SUZHOU UNIV +1

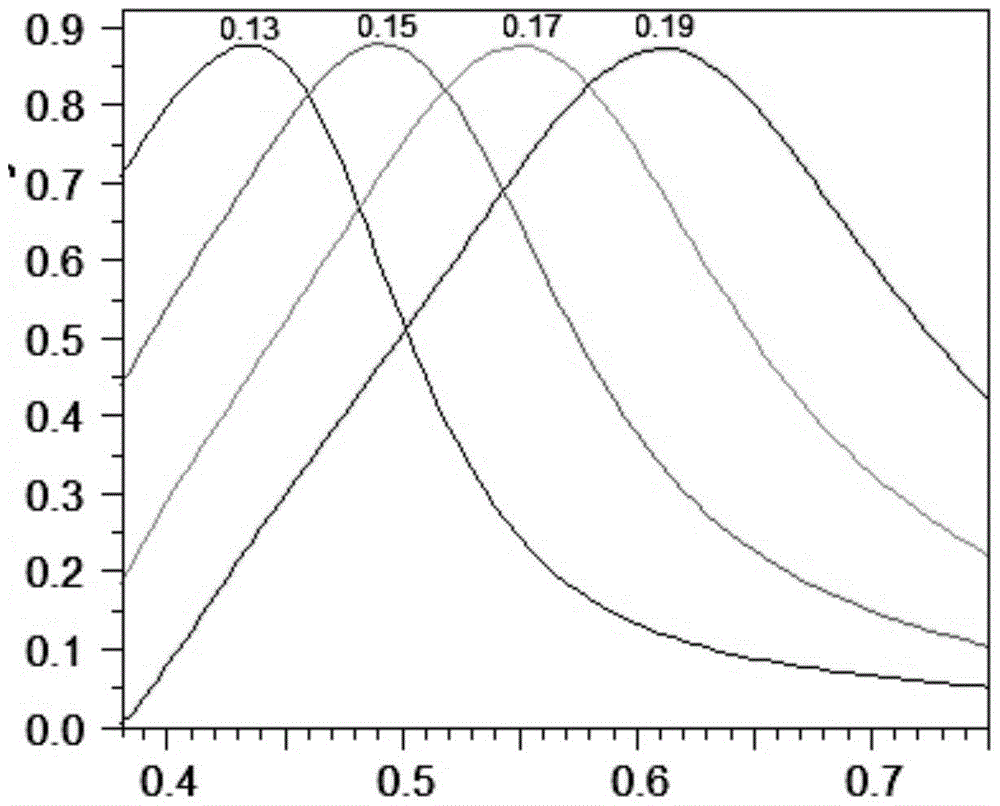

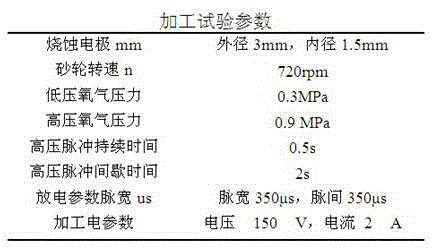

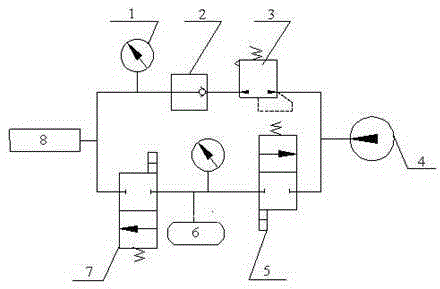

Discharge ablation machining method for difficult-to-machine metal materials based on quantitative high-pressure composite low-pressure intake system

ActiveCN103692038BSolve the problem of controllability of combustion and explosion reactionGuaranteed machining accuracyHigh pressure oxygenPulse power supply

The invention provides an intractable metal material discharge ablation processing method based on a quantitative high-pressure and low-pressure combination gas inlet system. According to the method, a hollow electrode is used as an electrode for inducing ablation; certain relative movement speed is kept between a workpiece and the electrode; spark discharge is generated between the electrode and an intractable metal material under the effect of a direct current or pulsed power supply; the surface of the intractable metal material is enabled to at a temperature which is higher than a material burning point temperature so as to be in an activation state by use of spark discharge; then quantitative high-pressure and low-pressure combination combustion-supporting gas output by the gas inlet system is introduced into an activation region through the interior of the hollow electrode; continuously introduced low-pressure gas and the metal which is in an activation state are subjected to a strong burning reaction so as to release heat; as the released heat quantity is greater than the dissipated heat quantity, ablation processing can be continuously performed; intermittently introduced quantitative high-pressure gas enables a quantitative activated material to be subjected to a fire blast reaction. By virtue of the gas inlet system, ablation processing is in a process of ablating the materials by virtue of continuous low-pressure oxygen induced combustion and quantitative high-pressure oxygen controllable fire blast.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of bacteria cellulose fiber-based carbon nanofiber knitted fabric

InactiveCN103184651BFine spatial networkHigh chemical purityWeft knittingCarbon fibresPolymer scienceCarbon fibers

The invention relates to a bacteria cellulose fiber-based carbon nanofiber knitted fabric, which is made through the following steps: adopting spinning and knitting technology to prepare a carbon nanofiber knitted fabric with a superfine bacteria cellulose fiber subjected to refining and carding treatment by the needling, and carrying out pyrolysis carbonization and graphitization. The preparation method has the benefits that the raw material source is wide; the price is low; the processing method is environment-friendly, safe, simple and efficient; the bacteria cellulose fiber-based carbon nanofiber knitted fabric gained after processing has wide application fields; and the potential economic benefit is huge.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of sulfur-modified thermosetting polymer proton exchange membrane and preparation method thereof

InactiveCN103367781BSimple processing methodEfficient processing methodSolid electrolyte fuel cellsRubber materialPolymer science

The invention belongs to the field of polymer electrolyte materials for fuel cells, and particularly relates to a sulphur-modified thermosetting polymer proton exchange membrane and a preparation method thereof. The proton exchange membrane comprises a base body rubber material, a metal unsaturated sulfonate, a vulcanizing activator, a vulcanizing accelerator and sulphur. According to the preparation method, in-situ sulfonation modification and in-situ sulphur modification of rubber are simultaneously completed in a high-temperature hot-pressing process, sulfonic acid groups are effectively grafted on a rubber molecular chain, and a large amount of cyclical sulfides is generated, thus the glass-transition temperature of the rubber is greatly increased, the rubber is transformed into thermosetting plastics, and therefore excellent size stability, heat stability, chemical stability and electrochemical stability are endowed to the proton exchange membrane. The preparation method provided by the invention is simple in process, high in efficiency and low in cost, and is environmental-friendly; the prepared sulphur-modified thermosetting polymer proton exchange membrane has the advantages of high proton conductivity, low methanol permeability, high size stability and the like, and can meet the use requirement of a direct-methanol fuel cell.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com