Machining method of micropore polyurethane sealing ring and tool clamp used for method

A technology of fixtures and processing methods, which is applied in the field of polyurethane materials, can solve problems such as low production efficiency and finished product qualification rate, poor exhaust, and difficulty in large-scale production, and achieve the goal of improving production efficiency and yield, and high-efficiency processing methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a more specific understanding of the technical content, features and effects of the present invention, the technical solution of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

[0034] The processing method of the microporous polyurethane sealing ring of this embodiment includes the following steps:

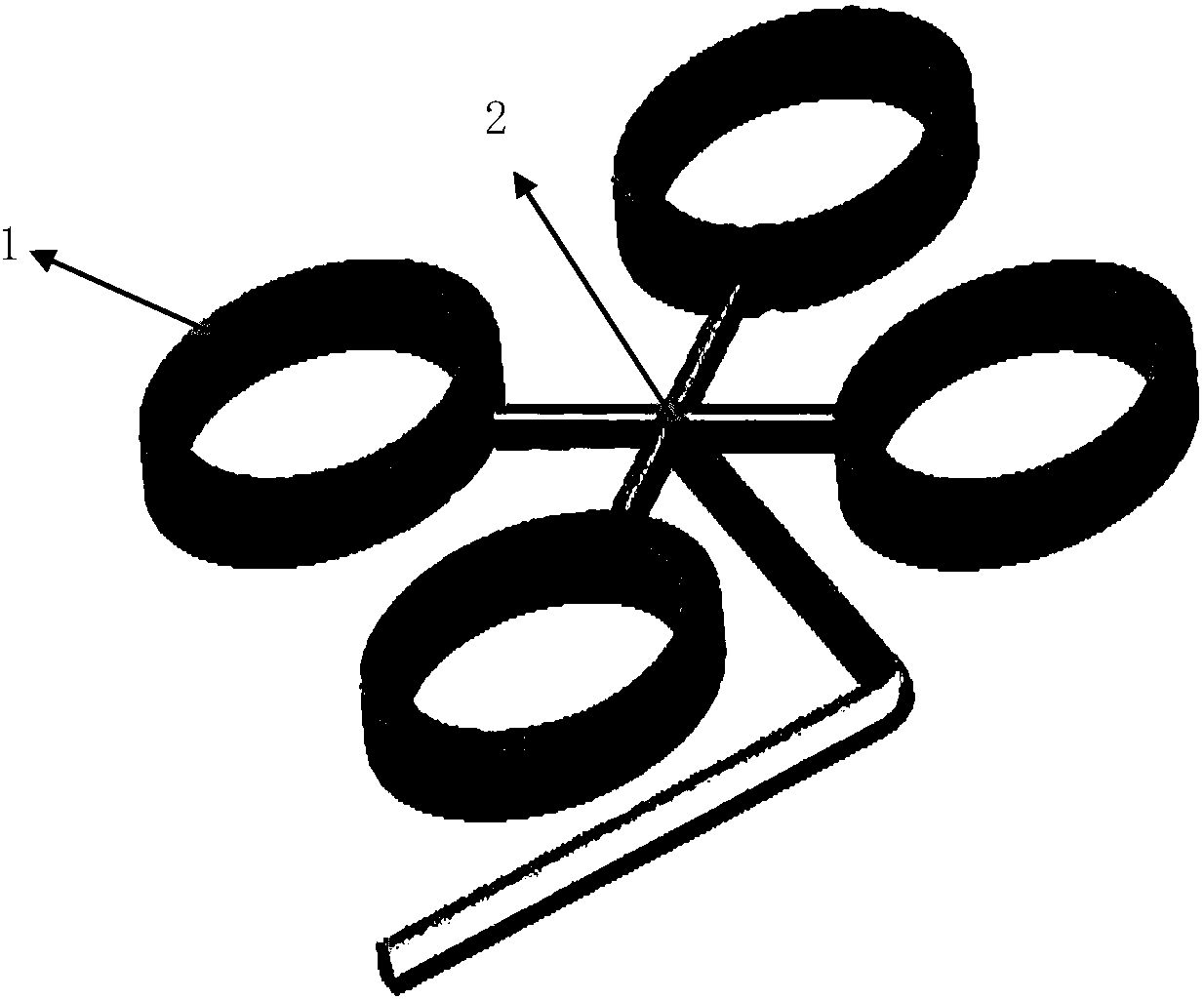

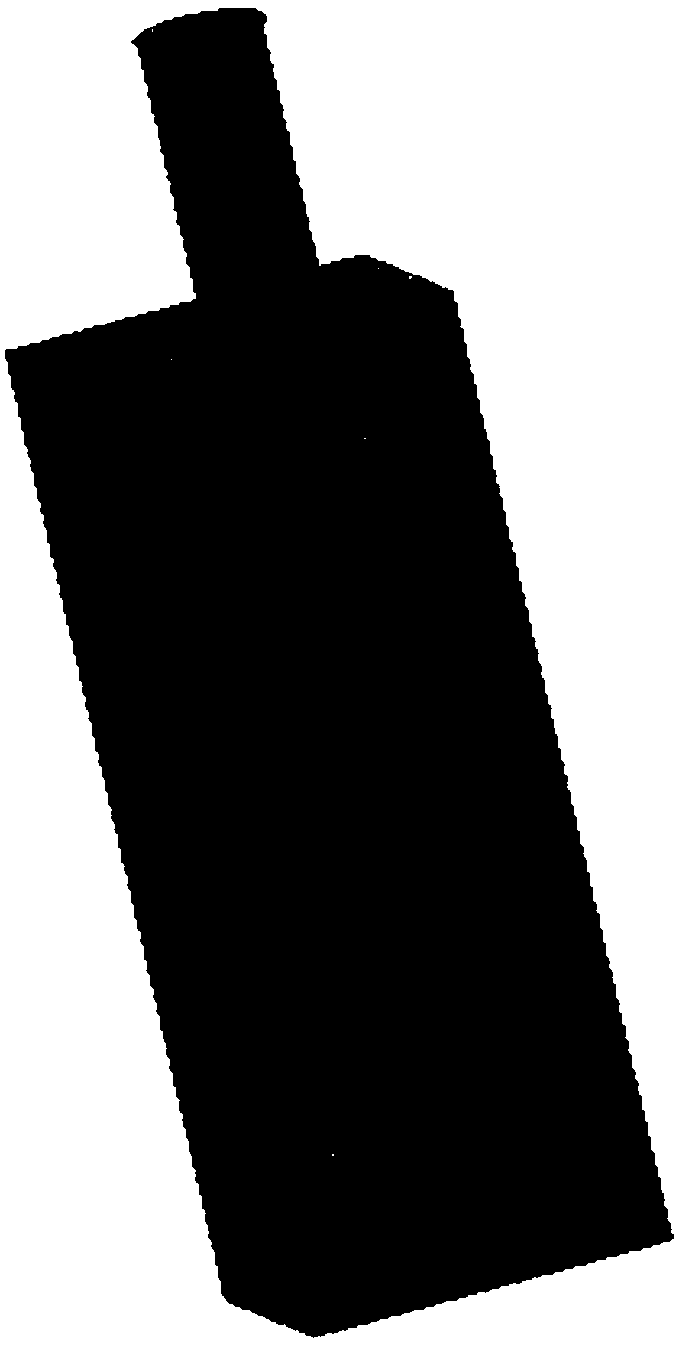

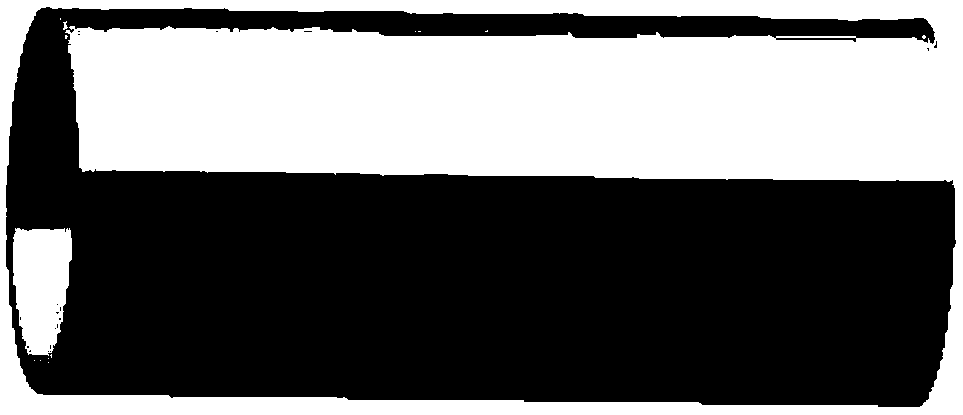

[0035] Step 1. Use a low pressure polyurethane injection machine to mix the microporous polyurethane liquid raw materials (usually A and B two-component materials, A material is usually polymerized polyol, and B material is usually isocyanate or isocyanate prepolymerized Body), composed of two mold halves (mold temperature 40~80℃, structure like figure 2 Shown) The bottom is injected into the two halves of the mold cavity, foamed for 5-10 minutes, then the mold is opened, and the microporous polyurethane blank casting is removed from the core to obtain image 3 The cylindrical micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com