Patents

Literature

58results about How to "The processing method is practical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sunflower seed and processing method thereof

InactiveCN102048195AReduce processing timeImprove burnt aromaFood preparationIllicium verumAdditive ingredient

The invention relates to a sunflower seed and a processing method thereof. The sunflower seed is prepared by taking a sunflower seed as a raw material, and anise, fennel, cassia, pericarpium citri reticulatae, clove, star anise, pepper, salt, saccharin sodium salt, sodium cyclamate, acesulfame-K and water as ingredients, and is prepared by the following steps of selecting, cooking, drying, frying, cooling and spraying fragrance. The sunflower seed is characterized by comprising the following components in parts by weight: 1-2 parts of anise, 1-2 parts of fennel, 0.5-1 part of cassia, 0.5-1 part of pericarpium citri reticulatae, 0.01-0.2 part of clove, 2-3 parts of star anise, 1-2 parts of pepper, 4-6 parts of salt, 0.05-0.1 part of saccharin sodium salt, 0.3-0.6 part of sodium cyclamate, 0.01-0.1 part of acesulfame-K and a proper amount of water. In the invention, as spices are adopted to cook and flavor the sunflower seeds, and a high-temperature frying technique is adopted to process the sunflower seeds, thus shortening the processing time of the sunflower seeds, maintaining the nutritive components and the healing effects of the sunflower seed, improving the uniform and thick burnt taste of the sunflower seed, and providing better mouth feel. The sunflower seed not only has reasonable and practical processing method, and practicality, but also has simple operation and good effect, and is beneficial for being popularized.

Owner:CHACHA FOOD CO LTD

Cucurbitae semina and its processing method

The present invention relates to a snack food-pumpking seed and its processing method. Said invention uses pumpking seed as raw material, uses jasmine flower as main ingredient and uses tea, licorice, edible salt, sweetening agent and water as auxiliary material, and makes them undergo the processes of screening, peeling, cooking, drying, stir-frying, cooling, spraying flavouring material, air-separating and packaging so as to obtain the invented product.

Owner:CHACHA FOOD CO LTD

Crispy-skin peanuts and processing method thereof

InactiveCN101972010AGood crispiness and mouthfeelExtended shelf lifeFood preparationSodium bicarbonateMonosodium glutamate

The invention relates to crispy-skin peanuts and a processing method thereof. The invention is characterized in that the crispy-skin peanuts are prepared by using peanuts as raw materials and starch, flour, white granulated sugar, malt syrup, plant oil, salt, monosodium glutamate, sodium bicarbonate and water as ingredients and by selecting, coating, molding, baking, mixing, cooling and packaging, wherein the ingredients comprise 30 to 36 weight parts of starch, 30 to 36 weight parts of flour, 10 to 12 weight parts of white granulated sugar, 6 to 8 weight parts of malt syrup, 2 to 3 weight parts of salt, 1.5 to 2.5 weight part of monosodium glutamate, 0.6 to 1 weight part of plant oil, 0.4 to 0.6 weight part of sodium bicarbonate and a proper amount of water. The crispy-skin peanut prepared through automatic production equipment has the advantages of proper crisp degree, excellent mouthfeel and long quality guarantee period, and the processing method simultaneously has the advantages of reasonability and practicality, good effect, simplicity of operation and contribution to wide popularization.

Owner:CHACHA FOOD CO LTD

Processing method of peanuts with shells

The invention relates to a processing method of peanuts with shells, which is characterized in that peanuts with shells are used as raw materials, garlic, ginger, aginomoto, table salt, sodium cyclamate, AK (Acesulfame-K) sugar, and water are used as auxiliary materials to form ingredients, and the processing method comprises the steps of: washing, punching, flavoring, drying, baking, cooling and packaging. since a punch press is used for punching on the peanuts with the shells before flavoring, a vacuum kettle is used for vacuum flavoring and antioxidant is added in the processing process, the invention ensures that the made peanuts with the shells has consistent taste, long quality guarantee period, strong fragrant and crisp flavor and favorable mouthfeel while preserving the nutrients of the peanuts. The invention has reasonable and practical processing method, simple operation and good effect and is beneficial to wide popularization.

Owner:CHACHA FOOD CO LTD

Method for processing assembling type bamboo floor

The invention discloses a processing method of an assembled bamboo floor, which utilizes bamboo with a short growth period and abundant resources as a raw material, and after selecting bamboo, breaking bamboo, cooking, drying, matching colors, cutting materials, assembling, and gluing, Put it in a hot press and glue it together, then polish it with a heavy sand machine, cut it with mechanical equipment, paint it and dry it, and then it will be the finished product. The whole assembly process is simple, practical, and the finished product has no peculiar smell, and the assembled bamboo floor has a compact structure, is not easy to deform, has good pressure resistance, and feels comfortable on the feet. It avoids mold, insects, deterioration and other phenomena during the use of bamboo flooring, and uses the top layer of bamboo chips, carbonized bamboo chips or other colored bamboo chips to be placed regularly in the top layer, which greatly enriches the surface of the bamboo floor. It has the advantages of anti-mildew, anti-corrosion, waterproof, not easy to deform, energy saving and environmental protection.

Owner:孙长桥

Method for processing semen trichosanthis

The invention relates to a method for processing semen trichosanthis. The method is characterized in that ingredient is prepared from semen trichosanthis serving as raw material and anise, fennel, liquorice, tangerine peel, clove, salt, sweetener and water serving as auxiliary materials by selecting, frying, dipping in soup, cooling and seasoning, winnowing and packaging. As the semen trichosanthis is fried by mechanical equipment, the nutrition and drug effect of the semen trichosanthis are maintained, and due to the aroma of spice mixed therein, the fried semen trichosanthis has rich toasty taste and good mouthfeel. Moisture control is performed during the frying so that the fried semen trichosanthis is easy to crack; and meanwhile, the antioxidant prolongs the shelf life of the product. The invention has the advantages of reasonable and practical processing method, simple operation and good effect and is favorable for wide popularization.

Owner:CHACHA FOOD CO LTD

Method for processing green beans

The invention relates to a method for processing green beans, which is characterized by comprising the following processes of selecting, soaking, deactivating, freezing, vacuum frying, stirring, cooling and packaging by taking the green beans as raw materials and taking garlic, ginger, monosodium glutamate, salt, water and palm oil as auxiliary materials. According to the method for processing the green beans, the green beans is fried by vacuum frying equipment, so the nutrition and the medicinal effect of the green beans can be remained; at the same time, the aroma of the auxiliary materials is melted into the green beans, so the produced green beans has a delicious crispy taste and a good mouth feel. Due to the vacuum frying technique and antioxidant which is used in the frying process, so the shelf life of the products is prolonged. The method for processing green beans is reasonable and practical, simple in operation and good in effect, and is suitable to be widely popularized.

Owner:CHACHA FOOD CO LTD

Internal adjustment high-calcium potato chips and processing method thereof

The invention discloses internal adjustment high-calcium potato chips and a processing method thereof. The internal adjustment high-calcium potato chips comprise the following ingredients in parts by weight: 80-120 parts of potato starch, 15-25 parts of white granulated sugar, 8-14 parts of oat and wheat bran powder, 5-10 parts of cucumber seed powder, 4-7 parts of shrimp powder, 3-6 parts of egg yolk powder, 20-30 parts of vegetable oil, 7-13 parts of ham meat, 6-12 parts of shrimp meat, 0.8-1.2 parts of common salt, 0.15-0.25 part of chicken essence, 1-1.5 parts of sodium bicarbonate, 3-5 parts of ammonium bicarbonate and an appropriate amount of water. The processed internal adjustment high-calcium potato chips which are not deep-fried and rich in nutrients have good crisp degree and taste. By adding the oat and wheat bran powder, the cucumber seed powder, the shrimp powder, the egg yolk powder and other raw materials, the potato chips are richer in nutrients, rich in calcium and good in calcium supplementing effect; by regular consumption, the absorption of calcium in a human body can be effectively promoted, osteoporosis can be prevented, and the internal adjustment high-calcium potato chips are particularly suitable for eating by adolescents in growth period and middle-aged and old people with bones which start to age. The processing method disclosed by the invention is reasonable and practical, simple to operate, good in effects and conductive to extensive popularization.

Owner:CHACHA FOOD CO LTD

Pignut and method of processing the same

The invention relates to a peanut food and its processing method, wherein the food is prepared from peanut, table salt, gourmet powder, sweeting agent and AK sugar through steps of refining, blanching,dedressing, pickling, frying, stirring and cooling down.

Owner:CHACHA FOOD CO LTD

Method for baking sunflower seeds

InactiveCN101606732AReasonable processing methodThe processing method is practicalFood preparationBiologyAgronomy

The invention relates to a method for baking sunflower seeds. The method comprises the following steps: winnowing raw materials; matching materials; boiling; baking; winnowing; selecting and picking; packaging; and warehousing. The invention not only has reasonable and practical processing method but also has simple operation, good effect, is beneficial to be widely popularized and can well ensure the benefits and the economy.

Owner:青岛清光食品有限公司

Watermelon seed with nine vitamins and preparation method thereof

The invention relates to a watermelon seed with nine vitamins and a processing method thereof. With small pieces of watermelon seeds as raw materials and star anise, cinnamon, orange peel, clove, salt, a sweetener, nine vitamins and the like as main ingredients, and the watermelon seeds are prepared by subjecting the materials to selecting, frying, dipping, stirring, cooling and spraying fragrance. Because the watermelon seeds are fried with the adoption of mechanized equipment, the nine vitamins such as vitamin A, vitamins B1-B6, vitamin C, vitamin M, vitamin D, vitamin K and the like are blended in the watermelon seeds when the self nutrition of watermelon seeds can be retained, thereby the prepared watermelon seeds have rich caramel aroma and crisp texture in taste and can also supplement multivitamins necessary for a human body. The processing method of watermelon seeds is reasonable and practical, is simple to operate, has good effects and is beneficial to wide popularization.

Owner:ANHUI TRUELOVE FOODS

Method for processing Chinese walnuts

ActiveCN102524847AChange peel and eatChange the status quo of peeling and eatingFood preparationFlavorIce water

The invention relates to a method for processing Chinese walnuts. According to the method, the Chinese walnuts is obtained by the steps of sieving the Chinese walnuts serving as raw materials, grading, bleaching, stir-frying at high temperature, quenching and cracking, drying and cooling. The method is characterized by comprising the following specific steps of: sieving and grading the Chinese walnuts to be processed according to sizes; bleaching the Chinese walnuts which are obtained through sieving and grading, and of which the outer diameters are 19.5 to 21.5 millimeters to remove impurities; adding the bleached Chinese walnuts into a rotary pot, and stir-frying at the temperature of between 200 and 220 DEG C for 25 to 35 minutes; quickly putting the Chinese walnuts which are stir-fried at high temperature into ice water at the temperature of 0 DEG C, so that the Chinese walnuts are cracked automatically; drying the Chinese walnuts which are cracked automatically at the ambient temperature of between 90 and 100 DEG C for 3 to 4 hours until moisture on the surfaces of the Chinese walnuts is dried; and cooling, putting the dried Chinese walnuts on an air cooling line, cooling to the normal temperature and packaging for sale. By the method, the unique flavors of the Chinese walnuts are kept to the maximum degree, and the processed Chinese walnuts are cracked completely and canbe peeled by eaters conveniently.

Owner:重庆洽洽食品有限公司 +1

Chinese medicinalal soft capsule

InactiveCN102139066APromote circulationGood lookingNervous disorderMetabolism disorderFlavorGinkgo leaf extract

The invention relates to a Chinese medicinal soft capsule, which is characterized in that: a ginkgo leaf extract, a red sage root extract, corn oil and grape seed oil serve as raw materials and auxiliary materials of soluble substances in the capsule, and the soluble substances are obtained through the steps of preparing, mixing, grinding and degassing; edible gelatine, glycerin and purified water serve as the raw materials of a capsule shell and are mixed, gelatinized and heated to obtain a glue solution; and the soluble substances in the capsule and the glue solution are prepared into the soft capsule through an automatic machine after being subjected to pelleting, shaping, drying, pellet washing, lamp inspection, packaging and final inspection. In the invention, as the ginkgo leaf extract, the red sage root extract, the corn oil, the grape seed oil and the like are prepared together, and the prepared Chinese medicinal soft capsule is brown in color and olivary in shape and has the advantages of attractive appearance and color, special flavor of the traditional Chinese medicine, reasonable and practical processing method, safety and good effect, and easiness for popularization.

Owner:安徽哈博药业有限公司

Dried duck and processing method thereof

InactiveCN101822389AMaintain nutrientsSpecial fragrance flavorFood preparationCold airAdditive ingredient

The invention relates to a dried duck and a processing method thereof. The dried duck is prepared from a duck serving as a raw material and salt, star anise, shallot, ginger, pepper and water serving as ingredients by cleaning, air drying, curing and air drying. The processing method is characterized in that: based on 250 to 350 weight parts of raw material duck, the following ingredients in part by weight are added: 50 to 60 parts of salt, 2 to 2.5 parts of star anise, 1.5 to 2.5 parts of shallot, 2 to 2.5 parts of ginger, 1.5 to 2.5 parts of pepper and 100 parts of water. Since flowing cold air at the temperature of below 8 DEG C permeates the inside of the duck to evaporate water inside the duck, the original nutritional ingredients and special flavor of the duck are kept, a processing technique is simple, and the duck is clean, sanitary and pollution-free, has long shelf life, is convenient to eat and can be storage at normal temperature. The processing method is reasonable and practical, has low cost, simple operation, good effect and wide popularization.

Owner:安徽兴程食品有限责任公司

Method for making fried melon seeds

The invention provides a method for making fried melon seeds. The method comprises the following steps: winnowing raw materials; preparing; boiling; frying; cooling; winnowing; selecting; packaging; and warehousing. The making method is not only reasonable and practical, but also has simple operation and good effect, contributes to wide popularization, and has excellent guarantee in benefit and economy.

Owner:青岛清光食品有限公司

Method for baking liquorice melon seeds

The invention discloses a method for baking liquorice melon seeds, which comprises the following steps of: winnowing raw materials, preparing materials, boiling, baking, winnowing, picking, packaging and warehousing. The prepared melon seeds have crisp mouthfeel, can keep the nutrition of the melon seeds, and the liquorice juice is fused into the melon seeds, so that the baked melon seeds have unique flavor and a certain effect of relieving cough and asthma. The processing method is reasonable and practical; and moreover, the method is easy to operate, good in effect, contributes to wide popularization and has good guarantee for benefits and economical efficiency.

Owner:汪洋

Method for producing meat type food for pet animals

InactiveCN1785037AHigh in nutrientsEasy to addAnimal feeding stuffWorking-up animal fodderRaw meatChemistry

Owner:张士平 +1

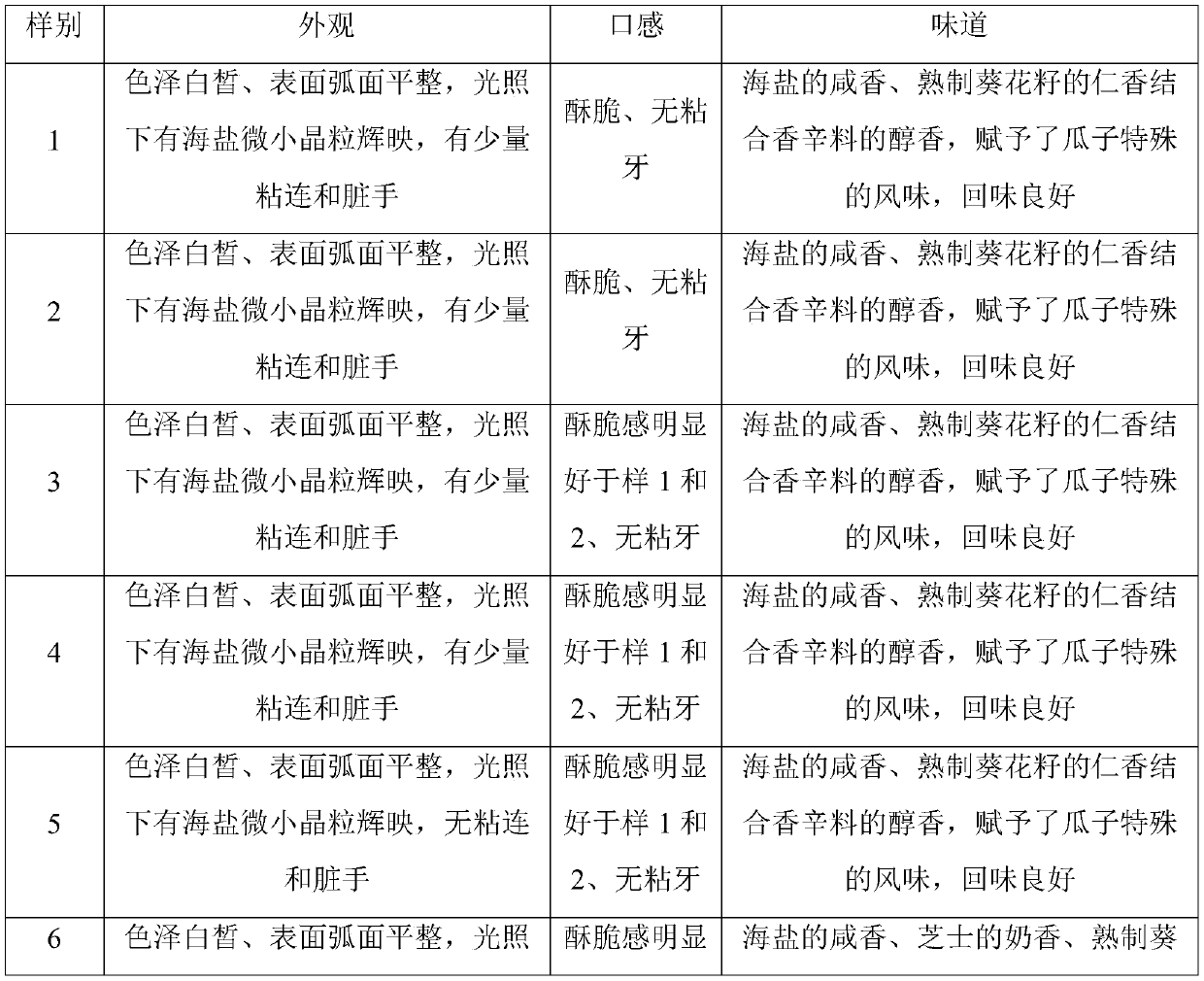

Sea salt taste original flavor sunflower seeds and preparation method thereof

PendingCN110419706AAttractive flavorUnique appearanceSeed preservation by dryingFood dryingSea saltFood flavor

The invention discloses sea salt taste original flavor sunflower seeds and a preparation method thereof, and belongs to the field of food processing.The preparation method comprises the steps that byrending a sea salt and spice together, original flavor sunflower seeds are stir-fried, through adhesion and drying, the sea salt taste original flavor sunflower seeds are obtained, and starch granulesadhere to the surfaces of the sunflower seeds; and the sea salt is added in two stages, and correspondingly regarded as a flavouring material and a dispersion medium in the two stages. According to the sea salt taste original flavor sunflower seeds, special appearance shapes such as special strip-type lines, swelling strip types and head-tip, tail-flat and middle-swelling appearance of the sunflower seeds are combined, the sunflower seeds are suitable for adhesion of the starch granules, adhesion excess is avoided to add sea salt special flavor given by sea salt granules to the sunflower seeds, at the same time, the synergistic effect with the starch granule is conducted, shaping and dispersing of the sunflower seeds are taken into account, and the technical problem is solved.

Owner:CHACHA FOOD CO LTD +1

Rhizoma polygonati and maca compound health food

InactiveCN105310072AReasonable processing methodThe processing method is practicalFood scienceSide effectOyster

The invention discloses a rhizoma polygonati and maca compound health food which is prepared by mixing the following components in parts by weight: 4-80 parts of maca powder, 2-60 parts of rhizoma polygonati powder, 0.6-30 parts of taurine, 0.6-30 parts of an oyster extract, 0.6-30 parts of a cervus elaphus linnaeus extract, 0.6-30 parts of a prepared rehmannia root extract, 0.5-15 parts of silica and 0.2-10 parts of magnesium stearate. The processing method of the health food disclosed by the invention is reasonable and practical, and the prepared product is non-toxic, does not have any side effect and can be taken for a long time. The product can relieve physical fatigue and has good effects on the crowd with symptoms such as spiritlessness, fatigue, mental tiredness and low resistance.

Owner:威海紫光金奥力生物技术有限公司

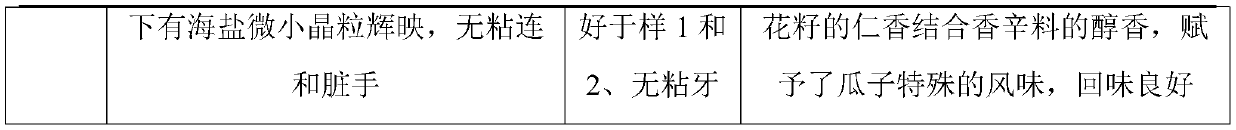

Process method for processing longitudinal shift cone gear on vertical milling machine

InactiveCN102632301ASimple processing methodShorten the timeGear-cutting machinesGear teethProcessing accuracyEngineering

The invention provides a process method for processing a longitudinal shift cone gear on a vertical milling machine. The process method comprises the following steps that: firstly, a first mandrel and a second mandrel are manufactured, the first mandrel is used for installing a gear sheet milling cutter and is arranged on the vertical milling machine, and the second mandrel is arranged on a center shaft of a horizontal index head of the vertical milling machine and is used for installing gear workpieces to be processed; a vertical index disc is arranged at one end of a work stable, and the index scribed line is regulated into zero; the horizontal index head is arranged on the vertical index disc surface, and the axial direction is parallel to the work stable of the vertical milling machine; the center line of the gear sheet milling cutter is a certain distance higher than the center line of the second mandrel; the vertical index disc rotates clockwise, the large end of cone teeth of the gear to be processed is used for the cutter setting and the cutter feeding, in addition, the work table is driven to longitudinally move, and a tooth groove is milled; and the horizontal index head is used for rotating a tooth angle, and the reprocessing is carried out; and the repeated operation is carried out in such a way. The process method has the advantages that the longitudinal shift cone gear can be processed on the existing vertical milling machine, the processing method is simple and practical, the time required by the gear processing is shortened, and the processing precision is high.

Owner:CHONGQING UNIV OF TECH

Health food capable of relieving physical fatigue

ActiveCN103504299BReasonable processing methodThe processing method is practicalFood ingredientsFood preparationSide effectAdditive ingredient

Owner:HAINAN ZHENGKANG PHARMA

Processing method of pumpkin powder

InactiveCN102524697ARealize large-scale productionGood colorFood shapingFood preparationPumpkin seedMoisture

The invention relates to a processing method of pumpkin powder. The pumpkin powder is prepared by using shellless pumpkin flesh as raw materials through material selecting, pretreatment, slicing and seed removal, color protection treatment, drying and crushing. The processing method is characterized in that the processing method comprises the following concrete processing steps that: a mature pumpkin with the yellow smooth and decayless peels is selected; the pumpkin is placed into water, dirt on the peel is cleanly washed, the pedicel is cut, and the peel is peeled; the pumpkin is split, the seeds and the flesh are removed, the flesh is cut into slices with the thickness being 4.5 to 5.5mm by a fruit and vegetable slicing machine; the pumpkin slices are placed into water of 88 to 92 DEG C to be boiled and bleached for 4.5 to 5.5 minutes and are then scooped up and drained; the pumpkin slices are placed into a rotary drying furnace to be dried, the drying temperature is 75 to 85 DEG C, the time is 5 to 6 hours, and the moisture content of the dried pumpkin slices is controlled at a value below 5 percent; and the dried pumpkin slices are placed into a crushing machine to be crushed into small-particle coarse materials, and then, the coarse materials are sent into a superfine crushing machine, are graded through a grading machine and are packed and sold. The processing method has the advantages that the scale production can be realized, and the pumpkin powder can realize good color, exquisite mouth feeling and easy brewing effects through deep processing. The processing method is reasonable and practical, in addition, the operation is simple, the effect is good, and the processing method is favorable for being widely popularized.

Owner:CHACHA FOOD CO LTD

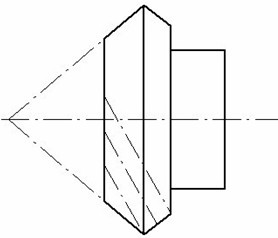

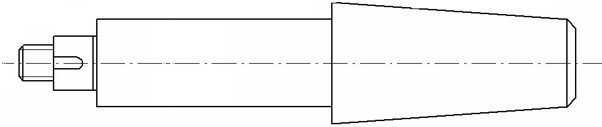

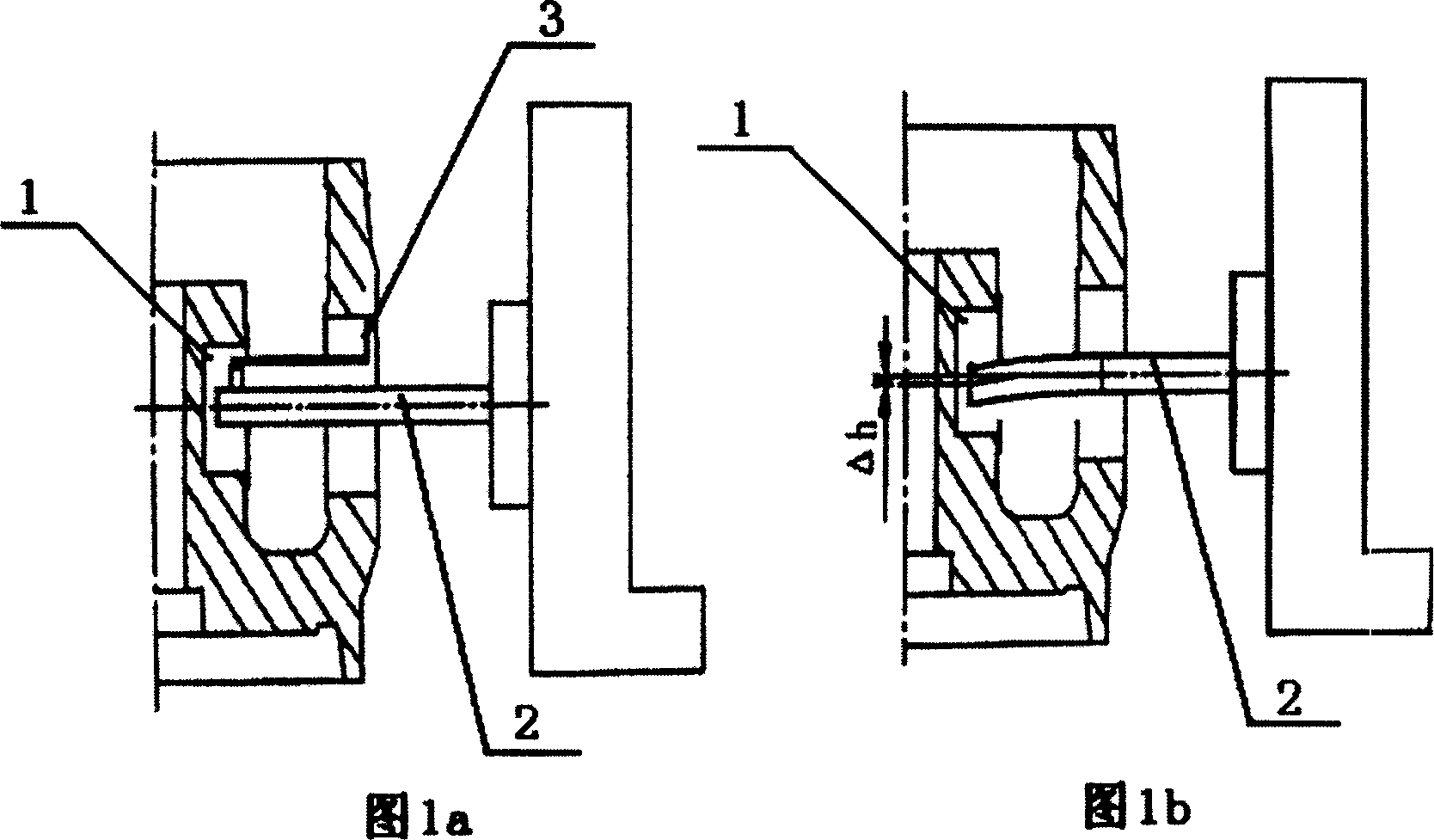

Rotary wheel body big and small axle holes coaxially processing method

InactiveCN1923461ASimple processing methodThe processing method is practicalAutomatic control devicesMeasurement/indication equipmentsEngineering

The invention relates to a method for coaxially processing the large and small axial holes of rotator, to confirm the coaxial degree. Wherein, it comprises that first processing large axial hole, then inserting boring main axle 2 into small axial hole to fine the jump of large axial hole via gage 3 at the part that boring axle is near to the end; via said jump. Increasing the boring main axle for 1 / 2 jump. The invention uses gage to test the jump Delth, to increase 1 / 2 Delth of main axle, with simple process and low cost.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

Potato chip with beef and black rice flavors and preparation method of potato chip

The invention discloses a potato chip with beef and black rice flavors and a preparation method thereof. The potato chip is prepared from the following raw materials in parts by weight: 100 parts of mashed potatoes, 2-3 parts of ginseng, 1-2 parts of fructus lycii, 2-3 parts of largehead atractylodes rhizomes, 0.5-0.8 parts of orange peels, 2-3 parts of kelp, 10-15 parts of stir-fried black rice flour, 5-7 parts of stick rice flour, 0.5-0.7 part of baking soda, 2-4 parts of hawthorn fruit powder, 5-7 parts of pork flavor powder, 15-18 parts of beef flavor powder, 2-3 parts of salt, 8-12 pars of xylitol, 4-6 parts of vegetable oil, 0.3-0.5 parts of monosodium glutamate, 2-3 parts of wine and a proper amount of water. The potato chip prepared with the method is unique in taste, wholesome, nutrient and convenient to eat; the obtained non-fried wholesome potato chip is crispy and tasty. The processing method is reasonable, practical, easy to use, good in effect and capable of being widely popularized.

Owner:王玉卿

Cranberry-almond kernels and processing method thereof

InactiveCN107019190AMeet nutritional needsCatering to the concept of healthy eatingFood scienceHealthy dietHealthy eating

The invention provides a processing method of cranberry-almond kernels. By adopting a technology of stirring and whipping, baking, bonding and aroma producing, the crispy mouthfeel and rich aroma of almond kernels and the sour-sweet taste of cranberries as well as the nutritional functions thereof are combined, and no additive is added, thereby meeting the requirements of consumers on taste and appearance and the needs for nutrients and conforming to the healthy diet idea of modern consumers. According to the processing method provided by the invention, by adding and whipping egg white, an appearance with good fullness and glossiness can be obtained, and nutrition is provided; meanwhile, since the egg white serves as a binder, the problem that the cranberries and the almond kernels bound with syrup cannot be separated easily is solved. The processing method provided by the invention is reasonable and practical; the operation is simple, and the effect is good; wide promotion is facilitated.

Owner:CHACHA FOOD CO LTD

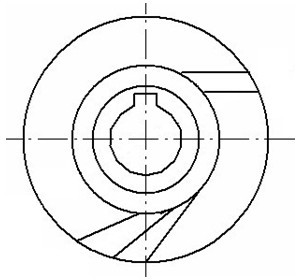

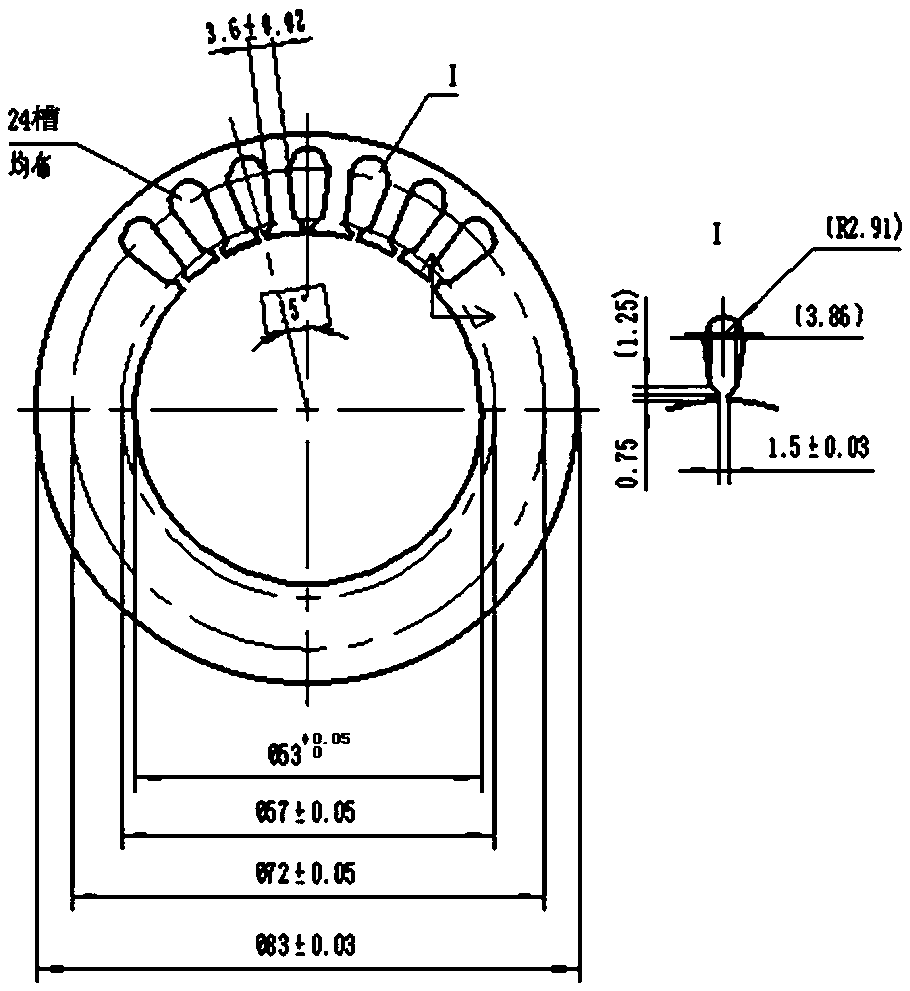

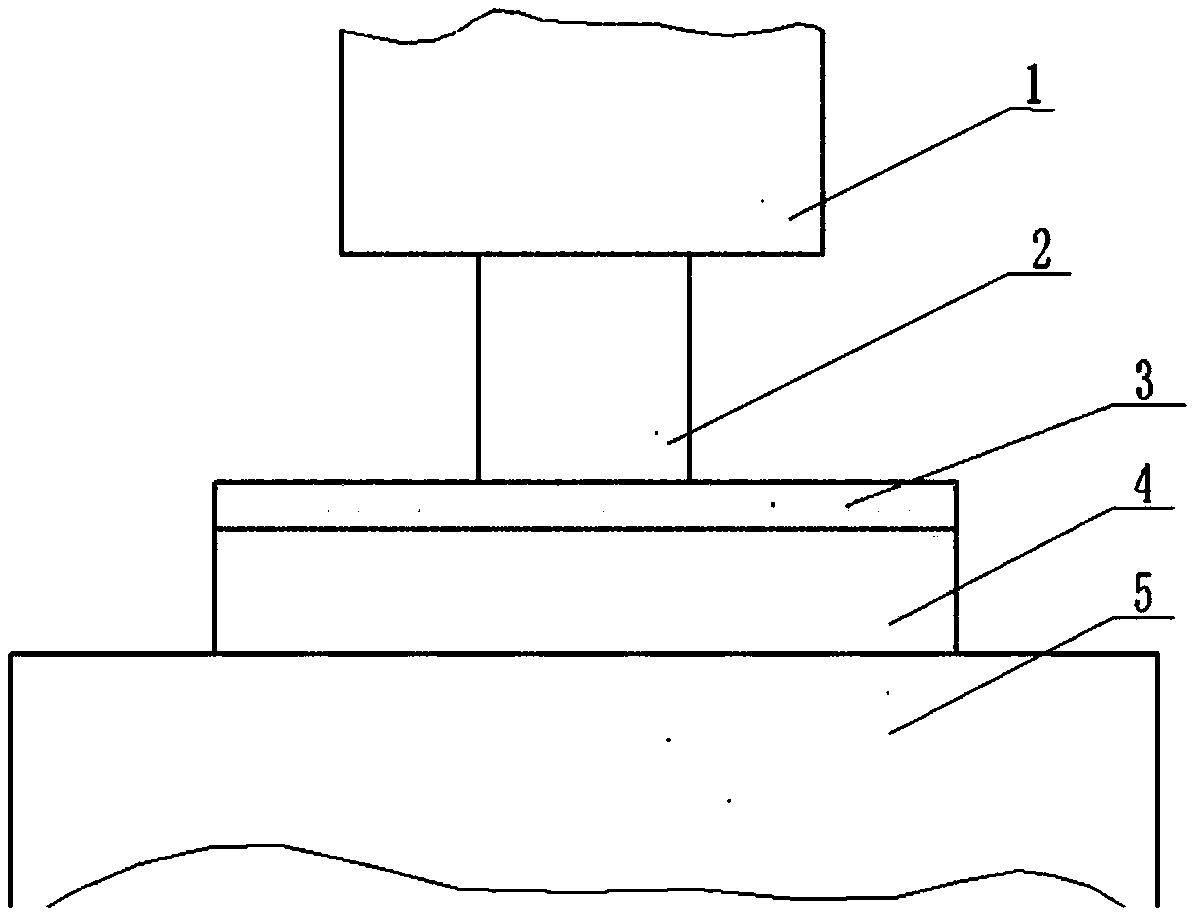

Machining method for thin and complex parts

InactiveCN109433902ASimple processing methodThe processing method is practicalManufacturing stator/rotor bodiesEngineeringMachining

The invention discloses a machining method for thin and complex parts. The machining method comprises the following steps that a concave die with a workpiece strip is firstly placed on a worktable; then a punch is placed on the workpiece strip; the working pressure of a hydraulic press is set; and the punch is used to press the workpiece strip, the concave die is elastically deformed by applying the pressure by the hydraulic press, the workpiece strip is deformed by stretching and pressing, and the punch continues to apply the pressure to make the workpiece strip completely separated, so thata workpiece with the same shape as a template is obtained. The machining method for the thin and complex parts has the advantages of simple and convenient operation, low die cost, low production costand high production efficiency, and can be used to manufacture not only insulating end plates but also thin parts of other materials.

Owner:XIAN MICROMOTOR RES INST

Processing method of spiced walnuts

The invention discloses a processing method of spiced walnuts. The processing method comprises the following steps of performing screening for classification, performing rinsing, and performing soaking until the walnuts are slotted but not broken; putting the slotted walnuts in seasoning juice, performing blending and cooking together for 10-30min, then pouring the walnuts and the seasoning juicein another tank, performing impregnation for 3-6h, fishing out the impregnated walnuts, and performing draining to remove the seasoning juice, wherein the mass ratio of the walnuts to the seasoning juice is 1 to (3-8), and the seasoning juice comprises the following raw materials in parts by weight: 5-20 parts of salt, 5-20 parts of white sugar, 1-10 parts of monosodium glutamate, 2-30 parts of star anises, 1-15 parts of Chinese prickly ash, 1-15 parts of fennel fruits, 0.5-8 parts of dried orange peel, 0.5-10 parts of radix angelicae dahuricae, 0.1-5 parts of Chinese cinnamon, 0.1-8 parts offructus momordicae, 0.1-8 parts of cloves, 0.1-8 parts of nutmeg, 0.1-8 parts of dried ginger, 0.1-8 parts of cumin seeds and 80-120 parts of water; and stir-frying the seasoned walnuts, performing baking, performing cooling, performing packaging, and performing sterilization to obtain the spiced walnuts. The spiced walnuts made by the processing method disclosed by the invention are free from heat toxins, are good in taste, rich in nutrition, and capable of nourishing bodies and preserving health, and people do not suffer from excessive internal heat after eating the spiced walnuts; and the processing method is reasonable and practical, simple to operate, good in effects and beneficial to extensive popularization.

Owner:安徽兆晨农业科技发展有限公司

Goose neck and processing method thereof

ActiveCN101637273BGreat tasteReduce processing timeFood preparationMonosodium glutamateAdditive ingredient

The invention relates to a goose neck and a processing method thereof. In the method, a raw goose neck is taken as material, salt, chili, five-spice power, light soy sauce, pepper, ginger, garlic, white sugar, monosodium glutamate and water are taken as subsidiary ingredients, and the goose neck is obtained through cleaning, salting, microwave treatment, decocting, dripping, cooling and sterilizing. The goose neck is characterized in that the subsidiary ingredients comprise the following components in weight proportion: 1-9 portions of salt, 3-4 portions of chili, 0.5-1.5 portions of five-spice powder, 0.5-1.5 portions of light soy sauce, 0.4-0.6 portion of pepper, 0.3-0.5 portion of ginger, 0.2-0.4 portion of garlic, 0.2-0.4 portion of white sugar, 0.15-0.25 portion of monosodium glutamate and proper portions of water. The invention not only provides a goose neck food for people, which is sanitary, has good taste and color and can be deeply processed through scale production; becausethe microwave technology is used in the course of processing, the goose neck is tastier, the processing time is reduced, and the production efficiency is improved. The processing method is reasonableand practical, has simple operation, good effect and easy popularization.

Owner:CHACHA FOOD CO LTD

Manufacturing method for crisp-fried green soya bean

The invention relates to a manufacturing method for crisp-fried green soya bean. The manufacturing method is characterized in that green soya bean is used as a raw material, and garlic, ginger, monosodium glutamate, salt, water and edible oil are used as accessorial materials and form seasonings; and steps consisting of careful choosing, soaking, enzyme deactivation, refrigeration, frying, blending with the seasonings, cooling and packaging are carried out to prepare the crisp-fried green soya bean. According to the invention, since frying equipment is employed to fry the green soya bean, the nutrients and the drug effect of the green soya bean are maintained and fragrance of the accessory materials are blended into the green soya bean; and thus, the prepared crisp-fried green soya bean has rich crisp-fried flavor and good taste. The method is reasonable and practical, is simple to operate, has good effect and can be conveniently and widely popularized.

Owner:董海伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com