Process method for processing longitudinal shift cone gear on vertical milling machine

A technology of vertical milling machine and bevel gear, which is applied in the direction of components with teeth, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of low precision and long time, and achieve high machining accuracy, shortened time and fast machining The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments.

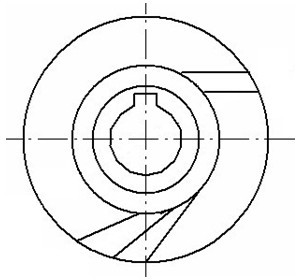

[0024] The process method of the present invention for processing tooth-shifting bevel gears on a vertical milling machine is characterized by including the following steps:

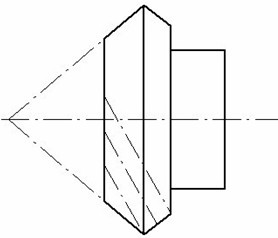

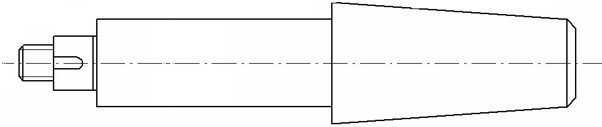

[0025] 1. According to the geometric dimensions of the bevel gear workpiece to be processed, the first mandrel and the second mandrel are made. The first mandrel is installed in the spindle hole of the vertical milling machine to install the gear cutter , The second mandrel is installed in the central axis of the horizontal indexing head of the vertical milling machine, and is used to install the gear workpiece to be processed;

[0026] 2. Install the vertical indexing disc on one end of the vertical milling machine table, and adjust the indexing line to zero; install the horizontal indexing head on the vertical indexing disc, the axial direction is the same as that of the vertical The worktable of the mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com